Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090797846538

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

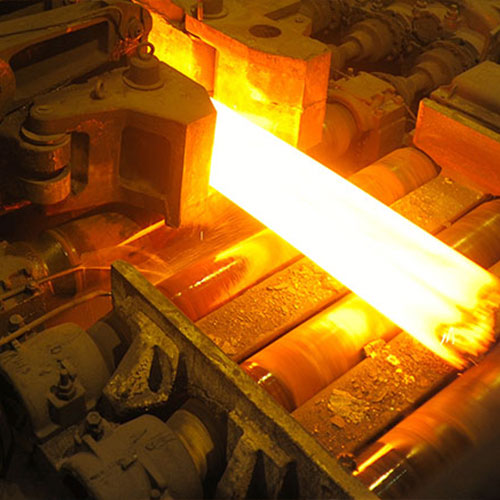

When it comes to high-performance tool steels, D2 steel stands out as one of the most trusted and preferred options among professionals and manufacturers. Known for its exceptional durability, impressive wear resistance, and incredible versatility, D2 steel has become an indispensable material in a variety of industries. From cutting tools and industrial machinery to die-making and manufacturing applications, D2 steel is renowned for its ability to withstand extreme conditions and provide reliable performance. But what exactly is D2 steel, and why is it consistently recommended by experts across the world?

In this blog, we’ll take an in-depth look at what D2 steel is and why it has earned its place as one of the top choices for industries that demand high-performance materials. We’ll explore its defining properties, examine its wide range of applications, and highlight five compelling reasons why D2 steel remains a favorite among industry professionals. Whether you’re a manufacturer, engineer, or hobbyist working on specialized projects, understanding the unique advantages of this steel can help you make well-informed decisions that will lead to more efficient and effective results. By learning about the composition, characteristics, and uses of D2 steel, you’ll gain a deeper appreciation of why it’s trusted in demanding environments.

From its strength and toughness to its exceptional resistance to wear and corrosion, D2 steel proves to be a reliable material that stands the test of time. This blog will provide you with the information you need to understand why D2 steel is considered a superior material and how it can enhance the quality and longevity of your projects.

What Is D2 Steel?

D2 steel is a high-carbon, high-chromium tool steel that belongs to the cold work steel family. It is classified as a semi-stainless steel due to its chromium content, which provides enhanced corrosion resistance compared to other tool steels. The material is known for its excellent hardness, wear resistance, and ability to retain sharp edges, making it ideal for demanding applications.

Key Properties of D2 Steel

- High Hardness: With a hardness range of 55-62 HRC (Rockwell Hardness Scale), D2 steel is exceptionally tough and durable.

- Wear Resistance: Its high carbon and chromium content make it resistant to abrasion, ensuring a longer lifespan for tools and components.

- Moderate Corrosion Resistance: While not fully stainless, D2 steel offers better resistance to rust and corrosion than many other tool steels.

- Dimensional Stability: It maintains its shape and size under stress, making it suitable for precision applications.

These properties make D2 steel a versatile and reliable material for a wide range of industrial and commercial uses.

Reason 1: Exceptional Wear Resistance

One of the primary reasons experts recommend D2 steel is its outstanding wear resistance. This property makes it an ideal choice for applications where tools or components are subjected to high levels of friction and abrasion.

Applications Highlighting Wear Resistance

- Cutting Tools: Blades, shears, and punches made from D2 steel retain their sharpness even after prolonged use.

- Dies and Molds: Its ability to withstand wear ensures longevity in stamping and forming operations.

- Industrial Machinery: Components like rollers and guides benefit from its resistance to surface degradation.

By choosing D2 steel, manufacturers can reduce the frequency of tool replacements and downtime, ultimately saving time and money.

Reason 2: High Hardness and Durability

D2 steel’s high hardness makes it exceptionally durable, capable of withstanding heavy loads and harsh conditions without compromising performance.

Benefits of High Hardness

- Edge Retention: Tools made from D2 steel stay sharper for longer, reducing the need for frequent sharpening.

- Impact Resistance: It can handle significant mechanical stress without cracking or breaking.

- Versatility: Its hardness makes it suitable for both heavy-duty and precision applications.

This durability ensures that tools and components made from D2 steel can endure the rigors of industrial use, making it a cost-effective choice in the long run.

Reason 3: Moderate Corrosion Resistance

While D2 steel is not fully stainless, its chromium content provides a level of corrosion resistance that surpasses many other tool steels.

Why Corrosion Resistance Matters

- Extended Lifespan: Components are less likely to degrade due to rust or corrosion, even in challenging environments.

- Reduced Maintenance: Less frequent cleaning and treatment are required to prevent corrosion.

- Versatility in Environments: It can be used in applications where exposure to moisture or chemicals is a concern.

This moderate corrosion resistance makes D2 steel a practical choice for industries where exposure to corrosive elements is unavoidable.

Reason 4: Excellent Dimensional Stability

D2 steel’s ability to maintain its shape and size under stress is another reason experts recommend it. This property is particularly important for precision applications where accuracy is critical.

Applications Requiring Dimensional Stability

- Precision Machining: Tools and components retain their exact specifications even under high stress.

- Mold Making: Ensures consistent quality in molded products.

- Gauges and Fixtures: Provides reliable measurements and alignments.

This stability ensures that products made from D2 steel meet stringent quality standards, making it a trusted material for precision engineering.

Reason 5: Cost-Effectiveness in the Long Run

While the initial cost of D2 steel may be higher than some alternatives, its long-term benefits make it a cost-effective choice.

Long-Term Financial Benefits

- Reduced Replacement Costs: Tools and components last longer, minimizing the need for frequent replacements.

- Lower Maintenance Costs: Its wear and corrosion resistance reduce the need for upkeep.

- Increased Productivity: Durable and reliable tools lead to fewer interruptions in operations.

By investing in D2 steel, businesses can achieve significant savings over time, making it a smart financial decision.

Comparison of D2 Steel with Other Tool Steels

To help you understand how D2 steel stacks up against other materials, here’s a table comparing its key properties with those of other common tool steels:

| Property | D2 Steel | A2 Steel | O1 Steel |

|---|---|---|---|

| Hardness (HRC) | 55-62 | 57-62 | 58-62 |

| Wear Resistance | Excellent | Good | Moderate |

| Corrosion Resistance | Moderate | Low | Low |

| Dimensional Stability | Excellent | Good | Good |

| Cost | Moderate | Low | Low |

This table highlights the unique advantages of D2 steel, making it a standout choice for many applications.

Conclusion

D2 steel is a remarkable material that offers a unique combination of hardness, wear resistance, and dimensional stability. Its moderate corrosion resistance and long-term cost-effectiveness make it a preferred choice for a wide range of applications. Whether you’re designing cutting tools, industrial machinery, or precision components, D2 steel provides the reliability and performance you need to succeed.

At Shandong Qilu Industrial Co., Ltd., we specialize in providing high-quality D2 steel products tailored to meet your specific requirements. If you’re ready to experience the benefits of this exceptional material, contact us today to learn more about our offerings and how we can support your projects. Let us help you achieve excellence with D2 steel!

FAQ

Q1: What is D2 steel commonly used for?

It is widely used in cutting tools, dies, molds, and industrial machinery due to its wear resistance and durability.

Q2: Can D2 steel rust?

While it is not fully stainless, D2 steel has moderate corrosion resistance and is less prone to rust than many other tool steels.

Q3: Is D2 steel suitable for knife making?

Yes, its high hardness and edge retention make it a popular choice for high-quality knives.

Q4: How does D2 steel compare to stainless steel?

D2 steel offers higher hardness and wear resistance but has lower corrosion resistance compared to stainless steel.

Q5: What industries benefit most from D2 steel?

Industries such as manufacturing, tooling, automotive, and aerospace benefit significantly from its properties.