Introduction

Hot work tool steels are essential materials in industrial applications where tools and dies operate under high temperatures. This blog aims to delve into the properties, applications, and advantages of hot work tool steels, offering a comprehensive guide for engineers, metallurgists, and enthusiasts alike.

What is Hot Work Tool Steel?

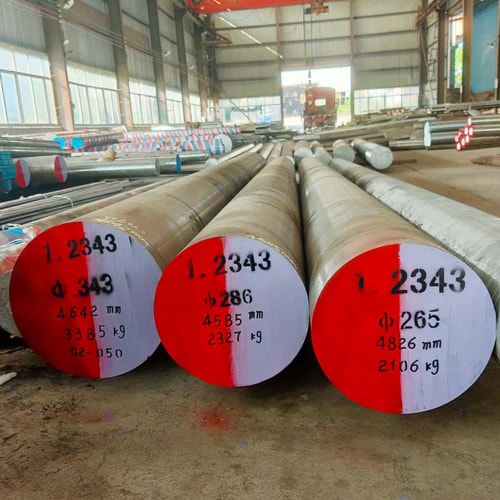

Hot work tool steels are a group of steels designed to withstand high temperatures during operation without losing their hardness, strength, or dimensional stability. They are primarily used in processes such as forging, extrusion, die casting, and hot stamping.

Chemical Composition and Microstructure

Hot work tool steels typically contain significant amounts of alloying elements such as chromium, tungsten, molybdenum, and vanadium. These elements contribute to their high temperature strength, wear resistance, and toughness. The microstructure is often martensitic or martensitic-bainitic, tailored to provide optimal mechanical properties.

Mechanical Properties

Typical Mechanical Properties of Hot Work Tool Steels

| Steel Grade | Hardness (HRC) | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Toughness (J/cm²) |

|---|---|---|---|---|

| H13 | 48-52 | 1800-2100 | 1500-1700 | 20-30 |

| H11 | 50-54 | 1900-2200 | 1600-1800 | 25-35 |

| H21 | 54-58 | 2000-2300 | 1700-1900 | 30-40 |

Heat Treatment of Hot Work Tool Steels

Heat treatment plays a crucial role in determining the final properties of hot work tool steels. Processes like annealing, quenching, and tempering are employed to achieve the desired hardness, toughness, and dimensional stability required for specific applications.

Applications of Hot Work Tool Steel

Hot work tool steels find applications in various industries, including:

Die Casting: Hot work tool steels are crucial for dies and inserts used in aluminum and magnesium die casting processes. These steels ensure the dies can withstand the high temperatures and pressures involved in casting molten metals, maintaining dimensional stability and prolonging tool life. Their high thermal conductivity also helps in efficient heat dissipation, reducing cycle times and enhancing productivity in die casting operations.

Forging: In the automotive and aerospace industries, hot work tool steels are indispensable for tooling used in hot forging operations. These steels are selected for their ability to maintain high hardness and strength at elevated temperatures, essential for shaping metals under extreme heat and pressure. The durability and wear resistance of hot work tool steels ensure that forging dies can withstand repeated impacts and thermal cycles, delivering precise and consistent component shapes with minimal downtime.

Extrusion: Hot work tool steels are extensively used in the manufacturing of dies and tooling for metal and plastic extrusion processes. These steels exhibit excellent thermal stability and resistance to deformation under pressure, ensuring consistent product dimensions and surface finish in extruded profiles and shapes. Their high hot hardness and abrasion resistance enable prolonged tool life, reducing maintenance costs and downtime in extrusion operations.

Hot Stamping: Tooling made from hot work tool steels is critical for hot stamping processes, particularly in the automotive industry for forming high-strength steels. These steels enable the production of complex and lightweight automotive components by facilitating rapid heating and quenching cycles without compromising on mechanical properties. The superior thermal fatigue resistance and high temperature strength of hot work tool steels ensure reliable performance in hot stamping dies, maintaining tight tolerances and surface quality in stamped parts.

Advantages and Challenges

Hot work tool steels offer several advantages such as high temperature resistance, excellent wear resistance, and good toughness. However, challenges include the need for careful heat treatment and susceptibility to thermal fatigue and oxidation at elevated temperatures.

Conclusion

In conclusion, hot work tool steels are indispensable in industries requiring tools and dies to operate under high temperatures and mechanical stress. Understanding their properties, proper heat treatment, and specific applications is crucial for optimizing performance and durability.

FAQ

Q: What are the key properties of hot work tool steels?

A:Hot work tool steels are known for their high temperature resistance, excellent wear resistance, and good toughness.

Q: What industries commonly use hot work tool steels?

A:Hot work tool steels are extensively used in die casting, forging, extrusion, and hot stamping industries.

Q: How does heat treatment affect hot work tool steels?

A:Heat treatment processes like quenching and tempering are used to adjust the hardness, toughness, and dimensional stability of hot work tool steels.