Introduction

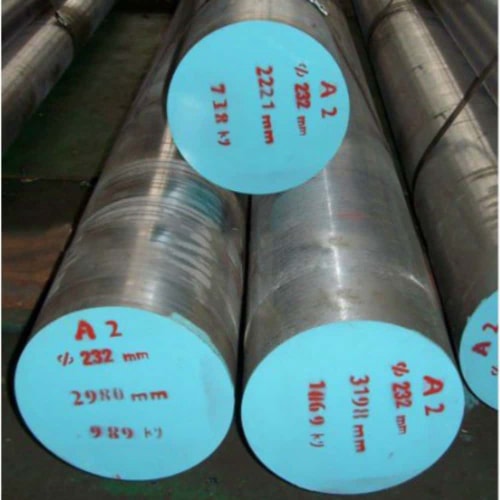

A2 tool steel stands out in the realm of industrial materials due to its remarkable combination of hardness, toughness, and wear resistance. This article provides a detailed exploration of A2 tool steel, essential for engineers, metallurgists, and anyone interested in its applications.

What is A2 Tool Steel?

A2 tool steel is a versatile member of the cold-work, air-hardening steel group. Its composition includes significant amounts of chromium, molybdenum, and vanadium, contributing to its excellent mechanical properties. With a carbon content between 0.95% to 1.05%, A2 steel offers a balance of hardness and machinability suitable for various cutting and forming applications.

Chemical Composition of A2 Tool Steel

Understanding the chemical composition of A2 tool steel is fundamental to comprehending its mechanical behavior and performance characteristics. The table below details the precise elemental composition:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.95 – 1.05 |

| Chromium (Cr) | 4.75 – 5.50 |

| Molybdenum (Mo) | 0.90 – 1.40 |

| Vanadium (V) | 0.15 – 0.50 |

Chromium enhances corrosion resistance and hardenability, while molybdenum and vanadium contribute to toughness and wear resistance, making A2 tool steel suitable for demanding applications.

Mechanical Properties of A2 Tool Steel

The mechanical properties of A2 tool steel make it highly desirable in tooling and machining applications. It typically exhibits a hardness range of 60-62 HRC after heat treatment, coupled with excellent dimensional stability and minimal distortion during quenching. Its high toughness ensures resistance to chipping and cracking under high-stress conditions, enhancing tool longevity.

Heat Treatment of A2 Tool Steel

A2 tool steel undergoes precise heat treatment processes to optimize its properties for specific applications. Annealing at controlled temperatures relieves internal stresses and ensures uniform hardness. Quenching in air or inert gas followed by tempering enhances hardness and toughness, striking a balance between hardness retention and impact resistance suitable for various tooling tasks.

Applications of A2 Tool Steel

A2 tool steel finds extensive use in diverse industrial sectors, including automotive, aerospace, and manufacturing. It is commonly employed in forming dies, blanking and piercing tools, thread rollers, and shear blades. Its ability to maintain cutting edge retention and withstand high-pressure applications makes it indispensable in precision machining and toolmaking.

Advantages of A2 Tool Steel

The advantages of A2 tool steel stem from its balanced composition and heat treatment capabilities. Its high wear resistance ensures prolonged tool life, reducing downtime and maintenance costs in production environments. Machinability is another notable advantage, allowing for intricate tool designs and precise machining operations. Dimensional stability under varying temperature conditions further enhances its reliability in critical applications.

Challenges and Considerations

Despite its numerous advantages, A2 tool steel presents challenges that engineers and manufacturers must consider. Its air-hardening properties can lead to dimensional changes during heat treatment, requiring careful control of heating and cooling rates. High tooling costs relative to other steel grades and the need for specialized equipment for heat treatment are additional factors to weigh in its adoption.

Conclusion

In conclusion, A2 tool steel remains a preferred choice for applications demanding high wear resistance, toughness, and dimensional stability. Its chemical composition, mechanical properties, and versatile applications make it an invaluable material in modern manufacturing and toolmaking industries. Understanding the nuances of A2 tool steel empowers professionals to optimize its use in diverse engineering projects, ensuring efficient and reliable performance.

FAQ

Q:What are the main properties of A2 tool steel?

A:A2 tool steel is renowned for its high wear resistance, toughness, and machinability, making it ideal for tooling and machining applications.

Q:What industries commonly use A2 tool steel?

A:A2 tool steel finds widespread use in automotive, aerospace, and manufacturing industries where high-performance tooling is essential.

Q:How does heat treatment affect A2 tool steel?

A:Heat treatment processes like annealing, quenching, and tempering significantly influence the hardness, toughness, and dimensional stability of A2 tool steel, enhancing its performance characteristics.

Q:What are the alternatives to A2 tool steel?

A:Alternatives include D2 tool steel and O1 tool steel, each offering distinct properties suitable for specific applications.