Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

Steel is one of the most widely used materials in the world due to its strength, durability, and adaptability. The engineering and manufacturing industries rely heavily on different grades of steel to fulfill diverse requirements ranging from construction and automotive applications to high-precision tools. While there are hundreds of classifications, certain types stand out because of their ability to perform across multiple industries and environments.

This article focuses on the top 9 versatile grades of steel today, with a particular emphasis on tool steel. Tool steel is especially valued for its hardness, resistance to abrasion, and ability to retain shape under high temperatures. Understanding these steel types can guide professionals and businesses in selecting the right material for long-term performance and cost-effectiveness.

What Makes a Grade of Steel Versatile?

Before diving into the top selections, it’s important to define what makes certain grades of steel more versatile than others. Versatility can be characterized by a steel’s ability to:

- Maintain strength and hardness under pressure

- Resist wear and corrosion

- Be heat-treated for specific mechanical properties

- Perform in multiple industrial contexts (cutting, forming, machining, etc.)

- Offer a good balance between cost and performance

Tool steels often excel in all these categories, which is why they are a focal point in this list.

Top 9 Versatile Grades of Steel You Should Know

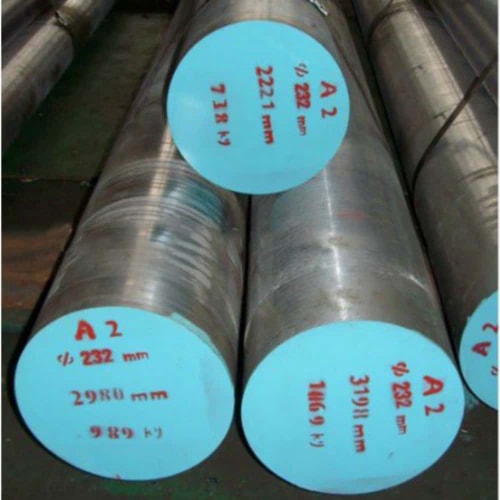

1. A2 Tool Steel

A2 is one of the most reliable grades of steel used in the tool-making industry. As an air-hardening variety, A2 offers an excellent combination of toughness and wear resistance. This grade performs especially well in applications that demand durability over extended use, such as blanking dies, forming tools, and cutting instruments. Among tool steels, A2 stands out because it resists distortion during heat treatment, making it a preferred choice for complex geometries. Due to its balanced alloy composition, A2 maintains its performance across different thermal and mechanical environments, further enhancing its versatility within the broader range of grades of steel.

2. D2 Tool Steel

D2 is a high-carbon, high-chromium tool steel known for exceptional hardness and superior abrasion resistance. Within the landscape of grades of steel, D2 is a standout for cold work operations including stamping dies, trimming tools, and shearing blades. Its ability to retain a sharp edge under repeated stress, along with its dimensional stability, makes it a favorite for precision cutting tools. Despite being harder to machine compared to other grades of steel, D2’s performance advantages often outweigh this limitation, especially when wear resistance is a priority.

3. O1 Tool Steel

O1 represents one of the most user-friendly grades of steel in the toolmaking category. As an oil-hardening steel, it is relatively easy to heat treat and machine, making it suitable for small-scale workshops and custom fabricators. O1 is commonly employed in knife blades, precision gauges, and woodworking tools where edge stability and moderate toughness are required. Though it doesn’t offer the extreme wear resistance of D2, its cost-effectiveness and workability make it a popular choice among various tool steel grades. For users seeking a balance between performance and ease of processing, O1 is a solid contender among the many grades of steel available today.

4. H13 Tool Steel

H13 is a hot-work tool steel that thrives in high-temperature applications, making it indispensable for die casting, extrusion dies, and forging dies. What makes H13 one of the most adaptable grades of steel is its ability to resist thermal fatigue and maintain dimensional stability under repeated heating and cooling cycles. This thermal resilience is vital in tooling operations where consistent mechanical properties must be maintained under stress. H13’s unique metallurgical profile allows it to serve a wide array of industries, reaffirming its place among the most trusted grades of steel for both performance and longevity.

5. S7 Tool Steel

Among impact-resistant grades of steel, S7 holds a significant reputation. Engineered to absorb heavy shock loads without cracking, S7 is often the go-to steel for punches, chisels, and other hand tools. Its moderate wear resistance complements its high toughness, offering a balance that few grades of steel can replicate. In environments where sudden force or vibration is common, S7 provides durability and reliability. Its ability to be heat-treated without losing structural integrity adds to its widespread use across multiple sectors.

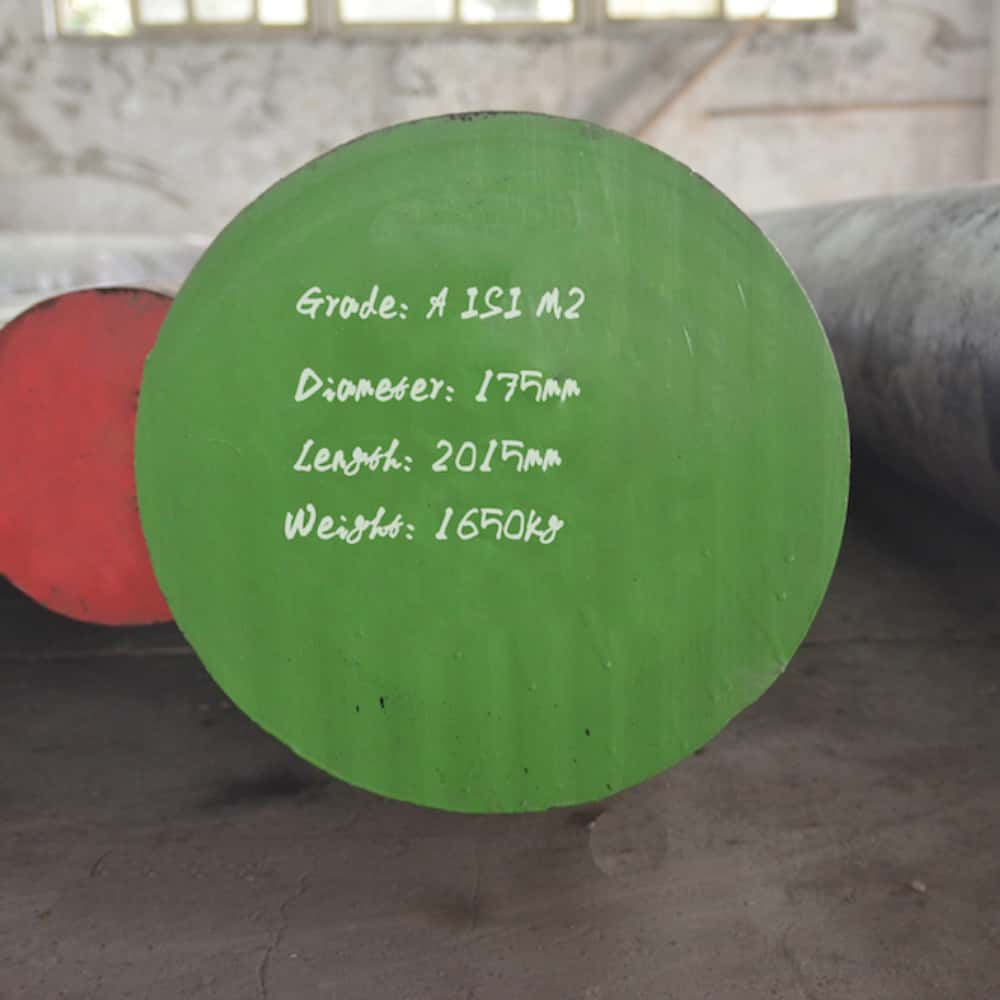

6. M2 High-Speed Steel

M2 is a popular high-speed grade used in cutting tools, such as drills and end mills. It maintains hardness at high operating temperatures and resists wear during fast machining. M2 offers an excellent balance of toughness and hardness.

7. A36 Structural Steel

Though not a tool steel, A36 is included here for its widespread application in construction and manufacturing. It is easy to weld and machine, making it a go-to grade for frames, plates, and general fabrication.

8. 4140 Alloy Steel

4140 is a chromium-molybdenum alloy known for its strength, fatigue resistance, and versatility. It’s used in automotive parts, hydraulic machinery, and even some tooling applications. It can be heat-treated to improve performance.

9. 440C Stainless Steel

440C is a martensitic stainless steel offering a rare blend of corrosion resistance and high hardness. Unlike other stainless grades, 440C can be heat-treated to achieve strength levels that rival traditional tool steels. It is commonly used in bearing assemblies, surgical instruments, and precision cutting tools. Although it’s technically a stainless steel, its utility in wear-heavy and corrosive environments makes it one of the more specialized grades of steel worth considering for demanding applications. For projects requiring both hygiene and durability, 440C delivers outstanding results.

Comparison Table of Versatile Grades of Steel

| Grade | Steel Type | Key Properties | Common Applications | Heat Treatable |

|---|---|---|---|---|

| A2 | Tool Steel | Wear resistance, air-hardened | Dies, cutting tools | Yes |

| D2 | Tool Steel | High hardness, dimensional stability | Stamping, forming tools | Yes |

| O1 | Tool Steel | Good machinability, oil-hardening | Knives, gauges | Yes |

| H13 | Tool Steel | Hot work resistance, thermal fatigue | Die casting, forging | Yes |

| S7 | Tool Steel | Shock resistance, moderate wear | Punches, chisels | Yes |

| M2 | High-Speed | Maintains hardness at high temp | Drills, end mills | Yes |

| A36 | Structural | Easy welding and machining | Frames, structural plates | Limited |

| 4140 | Alloy Steel | Fatigue resistance, versatility | Automotive, hydraulic parts | Yes |

| 440C | Stainless | Corrosion resistance, hardness | Bearings, blades | Yes |

Why Tool Steel Grades Are Widely Used

Tool steels dominate the versatile grades of steel due to their engineered compositions that suit a variety of industrial needs. Whether it’s cutting, shaping, or resisting wear, tool steels such as A2, D2, and H13 offer unmatched adaptability. Their high carbon and alloy content allow them to be customized through heat treatment, further enhancing their strength, hardness, and resistance properties.

They are especially useful in industries like:

- Aerospace

- Automotive

- Metalworking

- Manufacturing

- Mold making

These applications demand consistent performance and durability, which is where tool steel excels.

Conclusion

Selecting the right steel grade is crucial to the success of any engineering or manufacturing project. With so many options available, it’s easy to make the mistake of choosing a material that doesn’t offer the required combination of hardness, toughness, and machinability.

This guide has highlighted the top 9 versatile grades of steel that deliver consistent results across different applications. Tool steel, in particular, stands out for its performance and adaptability. By understanding the properties and typical uses of each grade, you can make more informed decisions that optimize cost, performance, and longevity.

Consult with material engineers or suppliers to ensure you choose the best grade for your application and processing capabilities.

FAQ

What is the most versatile tool steel grade?

A2 is often considered the most versatile due to its balance of toughness, wear resistance, and ease of heat treatment.

Can structural steel like A36 be used for tools?

A36 is not ideal for tools due to its low carbon content. It lacks the hardness and wear resistance needed for cutting or shaping tasks.

How important is heat treatment in tool steels?

Very important. Heat treatment customizes the properties of tool steel, enhancing its hardness, toughness, and durability.

Are stainless steels considered tool steels?

Some high-carbon stainless steels like 440C can be used in tool applications, but they are not classified as traditional tool steels.

What industries benefit most from versatile steel grades?

Aerospace, automotive, machining, and mold-making industries rely heavily on these steel types for their wide range of mechanical properties.