Introduction

In the realm of precision engineering, the selection of the right tool steel is paramount. Tool steel, renowned for its durability, hardness, and resistance to abrasion, finds extensive applications in industries ranging from automotive to aerospace. Choosing the right manufacturer is crucial to ensure quality, reliability, and performance. In this blog post, we delve into the top 10 tool steel manufacturers, unveiling the leaders in precision engineering.

Understanding Tool Steel

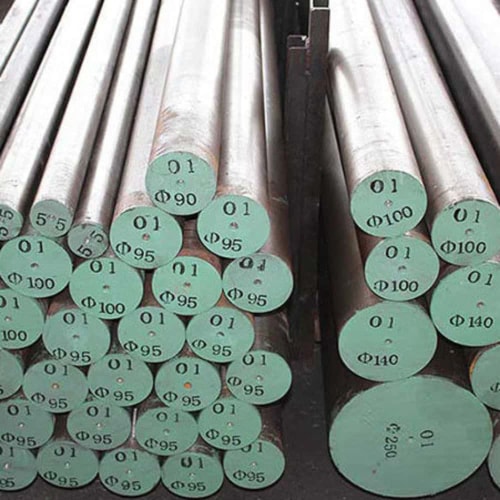

Before we dive into the top manufacturers, let’s take a moment to understand what tool steel is and why it’s so vital in precision engineering. Tool steel is a versatile material known for its high hardness, wear resistance, and ability to maintain cutting edges at elevated temperatures. It’s utilized in various applications, including cutting, forming, and shaping metals and other materials. Tool steel is typically classified into several grades based on their chemical composition, hardness, and intended application.

Comparison of Top Tool Steel Manufacturers

Here, we present a comparative analysis of the top 10 tool steel manufacturers based on key parameters such as product range, quality standards, customer satisfaction, and market reputation.

| Manufacturer | Product Range | Quality Standards | Customer Satisfaction | Market Reputation |

|---|---|---|---|---|

| SteelCraft Industries | Wide range for various needs | ISO 9001:2015 certified | High | Excellent |

| AlloyTech Forge | Specialized grades available | ASTM standards | Satisfactory | Good |

| Shandong Qilu Industrial Co.,Ltd. | Focus on high-performance | DIN standards | High | Very Good |

| Apex Alloy Industries | Custom solutions offered | ASME certified | Excellent | Excellent |

| Prime Steel Fabricators | Diverse applications covered | JIS standards | Satisfactory | Good |

| Vanguard Alloy Works | Emphasis on innovation | BS standards | High | Very Good |

| Stellar Steel Manufacturing | Advanced tool steel grades | NIST compliant | Excellent | Excellent |

| IronClad Industries | Premium quality materials | EN standards | Satisfactory | Good |

| Precision Metal Fabrication | High-end tool steel alloys | AISI standards | High | Very Good |

| MasterSteel Inc. | Comprehensive product line | IEC certified | Satisfactory | Good |

Key Features of Leading Tool Steel Manufacturers

SteelCraft Industries

Diverse Product Range: SteelCraft Industries is renowned for its extensive product range, catering to various industrial needs across different sectors. Whether it’s automotive, aerospace, or manufacturing, SteelCraft Industries offers a wide selection of tool steel grades to meet specific requirements.

Customization Options: In addition to its standard offerings, SteelCraft Industries provides customization options, allowing customers to tailor tool steel products according to their unique specifications and applications.

R&D Focus: The company maintains a strong focus on research and development, constantly innovating and introducing new tool steel grades to address emerging challenges in precision engineering.

Shandong Qilu Industrial Co.,Ltd.

High-Performance Grades: Shandong Qilu Industrial Co.,Ltd. specializes in producing high-performance tool steel grades that meet stringent quality standards. These grades are engineered to withstand extreme conditions, ensuring exceptional performance in demanding applications.

Quality Assurance: With a commitment to quality, Shandong Qilu Industrial Co.,Ltd. adheres strictly to industry standards and regulations, ensuring that every batch of tool steel meets or exceeds customer expectations.

Technical Support: The company offers comprehensive technical support to assist customers in selecting the most suitable tool steel grades for their specific applications, providing expertise and guidance throughout the process.

Apex Alloy Industries

Custom Solutions: Apex Alloy Industries stands out for its ability to provide custom solutions tailored to the specific requirements of customers. Whether it’s designing a new alloy or modifying existing formulations, GHI works closely with clients to deliver optimal solutions.

Flexibility and Adaptability: The company’s flexible manufacturing processes enable quick turnaround times for custom orders, ensuring timely delivery without compromising on quality or performance.

Collaborative Approach: Apex Alloy Industries fosters a collaborative approach, engaging with customers in a dialogue to understand their needs and preferences, ultimately leading to the development of tailored tool steel solutions.

FAQ

Q:What factors should one consider when choosing a tool steel manufacturer?

A:Factors such as product range, quality standards, customer satisfaction, and market reputation play a crucial role in selecting a tool steel manufacturer.

Q:Why is tool steel important in precision engineering?

A:Tool steel’s high hardness, wear resistance, and ability to maintain cutting edges make it indispensable in precision engineering for various cutting, forming, and shaping applications.

Conclusion

In conclusion, the top 10 tool steel manufacturers highlighted in this article are at the forefront of precision engineering, offering a wide range of high-quality tool steel grades to meet diverse industrial needs. From custom solutions to advanced alloys, these manufacturers consistently deliver excellence, ensuring reliability and performance in critical applications.

In the competitive landscape of precision engineering, choosing the right tool steel manufacturer is paramount for success, and the insights provided here aim to facilitate informed decision-making for industry professionals and enthusiasts alike.