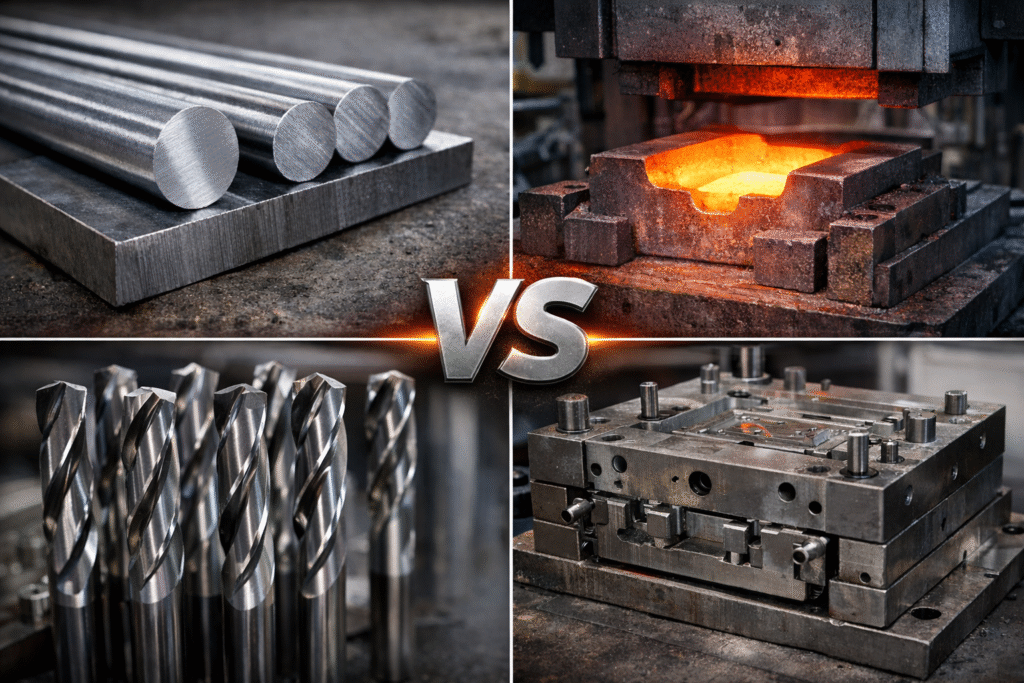

Tool steel is a specialized category of steel designed for manufacturing high-precision tools, molds, and dies that require exceptional hardness, wear resistance, and durability. Selecting the right material is critical for achieving optimal performance, efficiency, and product quality. This Tool Steel Comparison focuses on the most widely used types: Cold Work Tool Steel, Hot Work Tool Steel, High Speed Tool Steel (HSS), and Plastic Mould Steel, providing a detailed look at their performance, applications, and advantages to help manufacturers make informed choices.

Table of Contents

Tool Steel Comparison: Types and Characteristics of Cold, Hot, High-Speed, and Plastic Steels

Tool steel is engineered to withstand mechanical stress, friction, and heat during manufacturing processes. Unlike ordinary steel, tool steel maintains its hardness and structural integrity under challenging conditions. It is commonly used in cutting, stamping, molding, and forming operations, where precision and durability are crucial. Different types of tool steel are optimized for specific working environments, which makes understanding their properties essential for tool selection.

Tool Steel Comparison: Types and Characteristics of Cold, Hot, High-Speed, and Plastic Steels

Cold Work Tool Steel

Cold Work Tool Steel is designed for applications at room temperature. It features extremely high hardness, excellent wear resistance, and good fatigue strength. Cold work steel is ideal for cutting tools, stamping dies, and forming tools. Its main advantages include maintaining dimensional stability under heavy use and providing long-lasting performance in abrasive environments. However, it has relatively low toughness and can be brittle under high-impact conditions.

Applications: Cutting tools, stamping dies, forming tools

Key Advantage: High hardness and wear resistance

Hot Work Tool Steel

Hot Work Tool Steel is formulated to withstand high temperatures and thermal fatigue. It maintains strength and hardness even under repeated heating and cooling cycles, making it suitable for hot stamping dies, forging tools, and die-casting molds. Hot work steel offers excellent thermal shock resistance and can endure heavy loads at elevated temperatures. Its main drawback is higher production cost compared to cold work steel.

Applications: Hot stamping dies, forging molds, die-casting tools

Key Advantage: High-temperature resistance and thermal fatigue strength

High Speed Tool Steel

High Speed Tool Steel is engineered for high-speed cutting operations. It retains hardness at elevated temperatures generated during rapid machining, enabling faster cutting speeds and superior tool life. HSS is commonly used in drills, milling cutters, and cutting blades. Its exceptional wear resistance and heat resistance make it ideal for precision machining, though it comes at a higher cost.

Applications: Drills, milling cutters, cutting tools

Key Advantage: Extreme hardness and high-speed cutting capability

Plastic Mould Steel

Plastic Mould Steel is optimized for mold making, especially for injection and blow molding of plastics. It offers good toughness, corrosion resistance, and excellent surface finish, which ensures high-quality molded products. While it performs well under standard temperatures, it is not suitable for high-temperature forging or stamping processes. Its main advantage is producing precise, durable, and smooth molds.

Applications: Injection molds, blow molds, plastic forming tools

Key Advantage: Corrosion resistance and surface finish quality

Tool Steel Comparison – Hardness, Wear, Temperature, and Applications

| Type | Hardness | Wear Resistance | Temperature Resistance | Typical Applications |

|---|---|---|---|---|

| Cold Work | High | High | Low | Cutting, Stamping, Forming |

| Hot Work | Medium | Medium | High | Hot Stamping, Forging, Die Casting |

| High Speed | Very High | High | Medium | Drills, Milling, Cutting Tools |

| Plastic Mould | Medium | Medium | Low | Injection & Blow Molds |

How to Choose the Right Tool Steel – Insights from a Tool Steel Comparison

Choosing the right tool steel depends on the working environment, load conditions, temperature, and required precision. In this Tool Steel Comparison, Cold Work Tool Steel is ideal for high-wear operations at room temperature, Hot Work Tool Steel excels in high-temperature environments, High Speed Tool Steel is best for rapid machining and precision cutting, and Plastic Mould Steel ensures high-quality molds for plastic production. Balancing performance, durability, and cost is key to making the optimal tool selection.

Conclusion

Understanding the differences between Cold Work, Hot Work, High Speed, and Plastic Mould Tool Steel allows manufacturers to select the most suitable material for their specific applications. This Tool Steel Comparison highlights the unique advantages of each type: cold work steel for hardness, hot work steel for temperature resistance, high-speed steel for machining efficiency, and plastic mould steel for precision molding. Making the right choice improves tool longevity, operational efficiency, and overall product quality.