Introduction

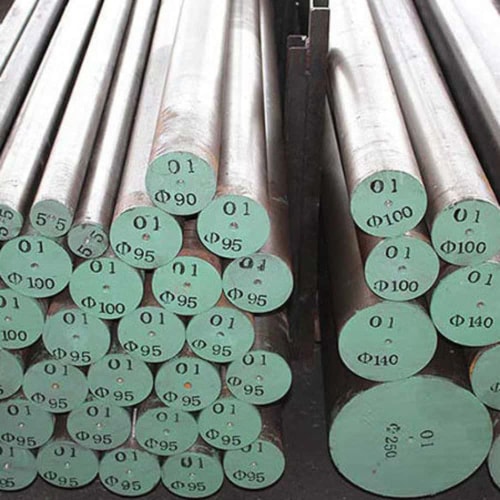

O1 tool steel, renowned for its versatility and reliability, stands as a cornerstone in precision engineering. This alloy, characterized by its excellent machinability, wear resistance, and dimensional stability, serves as a vital material across a myriad of applications. In this comprehensive exploration, we delve into the diverse facets of O1 tool steel, elucidating its properties, applications, and unparalleled utility in precision engineering.

Understanding O1 Tool Steel: Composition and Properties

At the heart of O1 tool steel lies a meticulously crafted composition, blending elements to perfection for optimal performance. Comprising primarily of carbon, chromium, manganese, and tungsten, this alloy boasts exceptional hardness, toughness, and edge retention. Its fine grain structure ensures superior machinability, enabling precise shaping and forming with ease. Moreover, O1 steel exhibits excellent dimensional stability, resisting distortion even under extreme conditions, thus rendering it indispensable in precision engineering endeavors.

Applications Across Precision Engineering Domains

The versatility of O1 tool steel transcends various domains within precision engineering, finding applications in machining, toolmaking, and die casting, among others. In machining, its high carbon content facilitates efficient cutting and shaping processes, enhancing productivity and precision. As a preferred choice in toolmaking, O1 steel delivers exceptional edge retention and durability, prolonging tool life and ensuring consistent performance. Furthermore, in die casting applications, its thermal conductivity and wear resistance prove invaluable, enabling the production of intricate components with unparalleled accuracy and reliability.

Exploring Case Studies: O1 Tool Steel in Action

To illustrate the practical efficacy of O1 tool steel, let us delve into a few compelling case studies showcasing its prowess in real-world applications:

- Precision Machining Components: In the automotive industry, O1 steel emerges as a preferred material for manufacturing precision machining components, such as gears and shafts. Its superior machinability and dimensional stability enable the production of high-precision parts, ensuring seamless integration into complex assemblies.

- Injection Molding Tools: Within the realm of injection molding, O1 steel finds widespread use in the fabrication of molds and dies. Its exceptional wear resistance and thermal conductivity enable prolonged tool life and enhanced productivity, facilitating the production of intricate plastic components with unparalleled accuracy.

- Cutting Tools and Blades: From industrial cutting tools to surgical blades, O1 steel demonstrates its versatility across diverse applications. Its high hardness and edge retention make it ideal for producing sharp, durable cutting implements, catering to the stringent demands of precision cutting operations.

Key Considerations and Maintenance Tips: Maximizing the Performance of O1 Tool Steel

While O1 steel exhibits remarkable properties, proper maintenance and handling are essential to ensure optimal performance and longevity. Here are a few key considerations and maintenance tips to maximize the performance of O1 steel components:

- Storage Conditions: Store O1 tool steel components in a clean, dry environment to prevent corrosion and contamination.

- Heat Treatment: Follow recommended heat treatment procedures to achieve the desired hardness and dimensional stability.

- Lubrication: Use appropriate lubricants during machining and forming processes to minimize friction and extend tool life.

- Regular Inspection: Conduct regular inspections to detect signs of wear or damage, and address any issues promptly to prevent degradation of performance.

Mechanical properties of O1 tool steel:

| Mechanical Property | Value |

|---|---|

| Hardness (Rockwell C) | 60-62 HRC |

| Tensile Strength | 250,000 psi |

| Yield Strength | 200,000 psi |

| Elongation at Break | 10-15% |

| Modulus of Elasticity | 30 x 10^6 psi |

| Impact Strength | 20-30 ft-lb |

FAQ

Q: What are the primary advantages of using O1 tool steel in precision engineering?

A: O1 tool steel offers exceptional hardness, machinability, and dimensional stability, making it ideal for producing high-precision components with superior performance and durability.

Q: How does O1 tool steel compare to other tool steel alloys?

A: Compared to other tool steel alloys, O1 tool steel boasts superior machinability and dimensional stability, making it particularly well-suited for precision engineering applications.

Conclusion

In conclusion, the versatility of O1 tool steel in precision engineering is truly remarkable, offering a myriad of advantages across diverse applications. From machining to toolmaking and beyond, this alloy continues to redefine the boundaries of precision and performance, empowering engineers and manufacturers to achieve unparalleled levels of quality and reliability. By harnessing the exceptional properties of O1 tool steel and adhering to best practices in maintenance and handling, practitioners can unlock new dimensions of innovation and excellence in their endeavors.