Table of Contents

Introduction

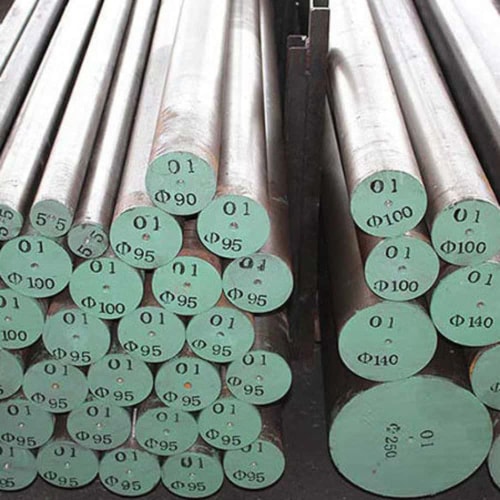

Medical grade steel is essential in healthcare, providing durability, precision, and biocompatibility. Tool steels such as O1, O2, M2, and M3 are widely used in high-precision surgical instruments, orthopedic tools, and critical structural components. Their combination of wear resistance, stability, and safety makes them ideal for modern medical environments, where repeated sterilization and rigorous performance are required.

Understanding Tool Steel Grades in Medical Applications

O1 Tool Steel: Precision and Stability

O1 is an oil-hardening tool steel with high hardness and excellent dimensional stability. It is ideal for cutting instruments such as scalpels and surgical scissors.

Its hardness typically ranges from 58–62 HRC, allowing instruments to maintain sharp edges through repeated sterilization.

O2 Tool Steel: Ease of Machining Without Compromising Performance

O2 shares similar hardness with O1 but is easier to machine, making it suitable for fine surgical tools and laboratory instruments.

The combination of hardness and machinability ensures both precision and efficient manufacturing.

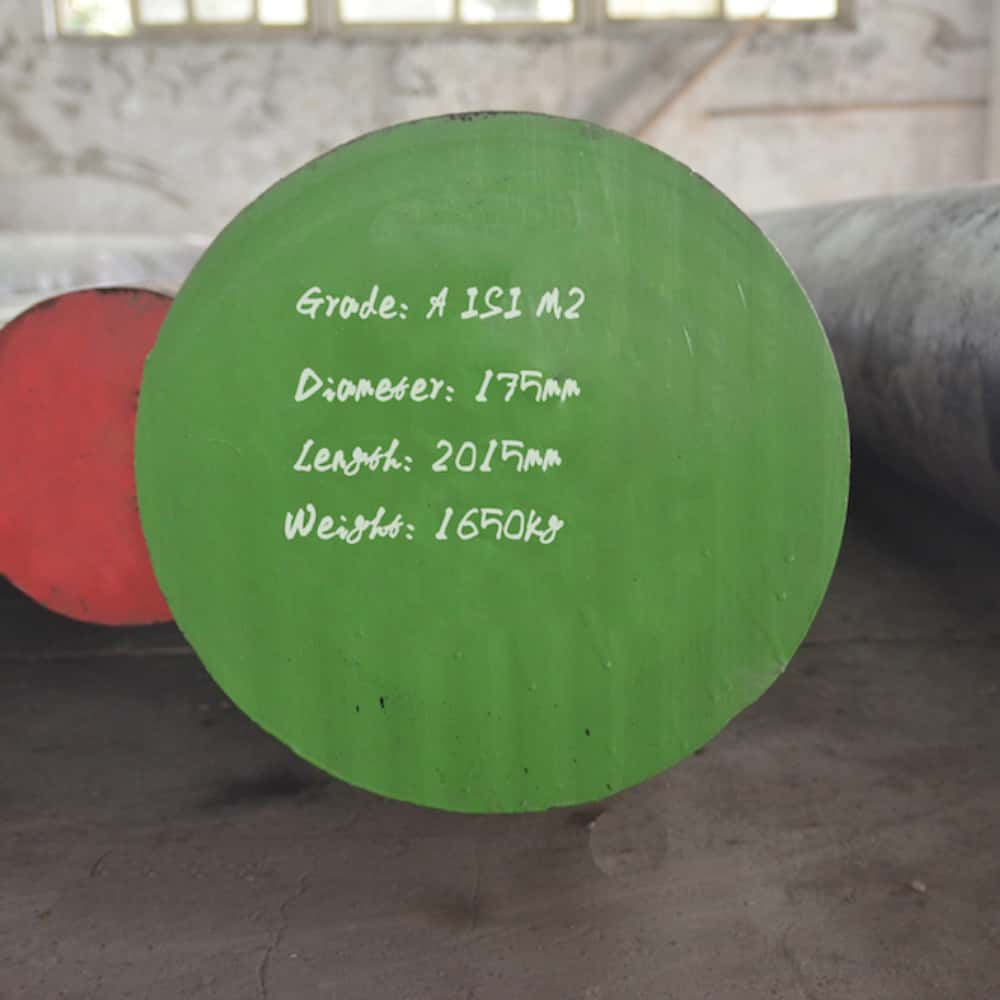

M2 High-Speed Steel: Durable and Wear-Resistant

M2 is a high-speed steel that offers exceptional wear resistance and toughness, maintaining performance under high-speed cutting or drilling.

Typical hardness: 62–64 HRC; typical tensile strength: 850–950 MPa.

It is widely used for orthopedic drills, implant manufacturing tools, and high-speed cutting instruments.

M3 High-Speed Steel: Heavy-Duty Medical Components

M3 steel provides superior toughness and long-term durability, making it ideal for structural supports and high-stress surgical tools.

Hardness: 63–65 HRC, tensile strength: 900–1000 MPa, ensuring reliability under repeated load and sterilization cycles.

Comparison of Tool Steel Grades for Medical Applications

| Steel | Hardness (HRC) | Tensile Strength (MPa) | Wear Resistance | Best Use | Key Advantages |

|---|---|---|---|---|---|

| O1 | 58–62 | 750–850 | Medium | Precision cutting instruments | Maintains sharpness and dimensional stability |

| O2 | 58–62 | 750–850 | Medium | Fine surgical tools | Easier machining for intricate instruments |

| M2 | 62–64 | 850–950 | High | Surgical drills, implants | Heat-resistant, durable under high-speed use |

| M3 | 63–65 | 900–1000 | Very High | Heavy-duty surgical tools, structural supports | Superior toughness, maintains precision under load |

This table provides quantitative data to help engineers and procurement specialists select the right steel for different medical applications.

Key Properties of Medical Tool Steel

Hardness and Wear Resistance

Medical Grade Steel, especially tool steel grades O1, O2, M2, and M3, retains its sharp edge over thousands of cycles. This property is crucial for surgical instruments, orthopedic drills, and other precision medical tools that undergo repeated cutting, drilling, or shaping. The high hardness of these Medical Grade Steels also reduces the frequency of maintenance and ensures long-term reliability in medical environments.

Dimensional Stability Under Sterilization

One of the defining features of Medical Grade Steel is its ability to maintain dimensional stability under heat sterilization. O1–M3 tool steels can withstand repeated autoclave cycles without losing shape or cutting precision, ensuring both safety and consistent performance of medical instruments. This makes Medical Grade Steel ideal for surgical, dental, and implant tools where accuracy is critical.

Biocompatibility and Corrosion Resistance

Medical Grade Steel is carefully alloyed and treated to provide biocompatibility, making it safe for instruments and implants that come into direct contact with human tissue. Additionally, these steels resist corrosion from bodily fluids and sterilization chemicals. O1, O2, M2, and M3 Medical Grade Steels are therefore widely used in high-demand medical environments where both safety and longevity are essential.

Machinability and Customization

Medical Grade Steel allows for precise machining and customization to meet the demands of modern healthcare. O1 and O2 tool steels are easier to machine for intricate surgical instruments, while M2 and M3 Medical Grade Steels, despite their higher hardness, can be CNC machined or heat-treated to achieve superior durability and high-speed cutting performance. This versatility makes Medical Grade Steel suitable for a wide range of medical applications, from delicate surgical tools to heavy-duty orthopedic equipment.

Applications of Medical Tool Steel

High-Precision Surgical Instruments

- O1/O2 steels are used in scalpels, scissors, and fine forceps.

- Their combination of hardness and stability ensures reliable precision for delicate procedures.

Wear-Resistant Surgical Tools

- M2/M3 steels are preferred for drills, reamers, and orthopedic cutting tools.

- High wear resistance allows instruments to perform under continuous use without losing sharpness.

Critical Structural Components

- M3 steel is commonly used for surgical table supports, implant guides, and critical frames.

- High toughness ensures structural stability during operations.

Implant Manufacturing

- M2 and M3 tool steels are used in custom orthopedic implants.

- The combination of precision machining, wear resistance, and biocompatibility ensures implants meet medical standards.

Selecting the Right Steel Grade

Comparing Steel Grades in Real Applications

- O1 vs O2: Both suitable for cutting tools; O2 is easier to machine for complex shapes.

- M2 vs M3: High-speed and wear-intensive tools; M3 preferred for structural support due to superior toughness.

Practical Selection Guide

- Fine precision instruments: O1/O2

- High-speed drills or implant tools: M2

- Heavy-duty surgical tools or support components: M3

Processing and Surface Treatment

Polishing and Mirror Finishing

Reduces bacterial adherence and enhances sterilization efficiency.

Heat Treatment

Improves hardness, wear resistance, and dimensional stability, especially critical for M2/M3 steels.

Coating and Plating

Optional coatings improve corrosion resistance and biocompatibility for surgical and implant applications.

Maintenance and Longevity of Medical Tool Steel

Cleaning and Sterilization

- Follow manufacturer-recommended sterilization cycles for O1–M3 instruments.

- Avoid harsh chemicals that could reduce hardness or damage coatings.

Inspection and Preventive Maintenance

- Regularly inspect for dulling, surface pitting, or structural deformation.

- Proper maintenance ensures long-term precision, reliability, and safety.

Troubleshooting Common Issues

- Dulling: Usually from extended use or improper sterilization.

- Surface corrosion or pitting: May result from chemical exposure.

- Dimensional changes: Rare if heat treatment and sterilization cycles are properly controlled.

FAQ

What are the main differences between O1, O2, M2, and M3 steel for medical instruments?

O1/O2 are best for precision cutting tools, while M2/M3 are more wear-resistant and suited for high-speed or structural applications.

Can M2 or M3 steel be used for implants?

Yes, with proper surface treatment and biocompatibility measures, M2/M3 steels are suitable for orthopedic implants.

How do I maintain high-speed surgical instruments made of M2/M3 steel?

Regular inspection, sterilization, and adherence to heat treatment recommendations ensure long-term performance.

Which steel is best for long-lasting surgical instruments?

O1/O2 for precision cutting tools; M2/M3 for wear-intensive, high-speed, or structural instruments.

Are medical tool steels safe for direct contact with the human body?

Yes, biocompatible grades with proper surface treatment are safe for instruments and implants.

Conclusion

Medical tool steels—O1, O2, M2, and M3—play a critical role in modern healthcare. From high-precision surgical instruments to wear-resistant tools and critical support structures, these steels ensure precision, durability, and biocompatibility. By selecting the appropriate grade, applying proper processing and surface treatment, and following best practices for maintenance, medical professionals and manufacturers can meet the strict standards of modern medical applications.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀