Introduction

Heat treating O1 tool steel is a critical process that can significantly enhance its performance. By carefully controlling the heating and cooling rates, it is possible to achieve the desired properties, such as hardness, toughness, and wear resistance. In this blog post, we will explore the intricacies of heat treating O1 tool steel, including the benefits, procedures, and factors that can affect the outcome.

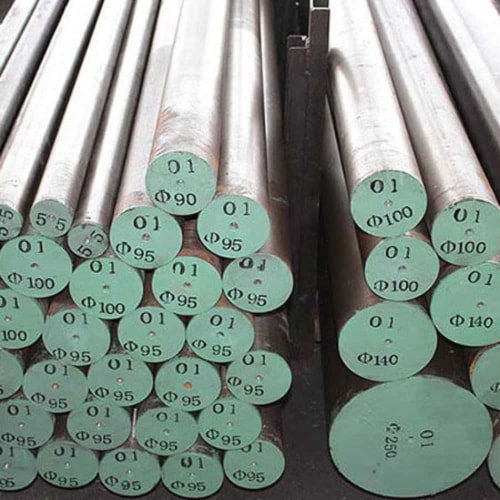

O1 tool steel is a versatile alloy that is widely used in various industries, including manufacturing, automotive, and aerospace. Its excellent balance of hardness, toughness, and wear resistance makes it an ideal choice for cutting tools, dies, and other components that require a durable and long-lasting material.

Understanding O1 Tool Steel

Before delving into the heat treating process, let’s briefly discuss O1 tool steel itself. This alloy is primarily composed of iron, carbon, and small amounts of other alloying elements. Its unique composition grants it exceptional properties, making it a valuable material for a wide range of applications.

O1 tool steel is particularly well-suited for applications that require:

- High hardness: For resisting wear and abrasion.

- Excellent toughness: For preventing fractures and ensuring durability.

- Enhanced wear resistance: For extending the lifespan of cutting tools and other components.

The Science Behind Heat Treating

Heat treating O1 tool steel involves heating the steel to a specific temperature, holding it there for a certain period, and then cooling it at a controlled rate. This process alters the microstructure of the steel, resulting in desired properties.

The heat treating process typically involves the following steps:

- Heating: The steel is heated to a temperature known as the austenitizing temperature, which is usually between 1200°F and 1300°F.

- Soaking: The steel is held at the austenitizing temperature for a specific period to ensure that the microstructure changes uniformly throughout the material.

- Quenching: The steel is rapidly cooled, typically in oil, to transform the austenite into martensite. Martensite is a hard but brittle phase that gives the steel its hardness.

- Tempering: The martensite is tempered at a lower temperature to improve its toughness and reduce its brittleness.

Benefits of Heat Treating O1 Tool Steel

Heat treating O1 tool steel offers numerous advantages, including:

- Increased hardness: For enhanced resistance to wear and abrasion.

- Improved toughness: For preventing fractures and ensuring durability.

- Enhanced wear resistance: For extending the lifespan of cutting tools and other components.

- Stress relief: For preventing cracking and distortion.

The Heat Treating Process

The heat treating process for O1 tool steel is a critical step in optimizing its performance. By carefully controlling the heating and cooling rates, it is possible to achieve the desired properties.

The heating rate is an important factor in heat treating O1 tool steel. Heating too quickly or too slowly can affect the microstructure and properties of the steel.

The soaking time is also crucial. Insufficient soaking time can lead to incomplete transformation of the microstructure.

The quenching medium can significantly influence the cooling rate and the resulting microstructure.

The tempering temperature and time determine the balance between hardness and toughness.

Factors Affecting Heat Treating Results

Several factors can influence the outcome of heat treating O1 tool steel, including:

- Heating rate: Heating too quickly or too slowly can affect the microstructure and properties of the steel.

- Soaking time: Insufficient soaking time can lead to incomplete transformation of the microstructure.

- Quenchant: The type of quenchant used can significantly affect the cooling rate and the resulting microstructure.

- Tempering temperature and time: The tempering temperature and time determine the balance between hardness and toughness.

Common Heat Treating Mistakes and How to Avoid Them

- Incorrect heating temperature: Using an incorrect heating temperature can lead to incomplete transformation of the microstructure.

- Insufficient soaking time: Insufficient soaking time can result in non-uniform properties.

- Quench cracking: Quench cracking can occur if the steel is cooled too rapidly or if there are sharp corners or stress concentrations.

- Overtempering: Overtempering can reduce the hardness of the steel.

Heat Treating Equipment

To perform heat treating O1 tool steel, you will need the following equipment:

- Furnace: A furnace capable of reaching the required temperatures.

- Quenchant: A suitable quenchant, such as oil or water.

- Thermometer: To accurately measure the temperature.

- Safety equipment: Protective gear, such as gloves and safety glasses.

Table: Common Quenchants for O1 Tool Steel and Their Characteristics

| Quenchant | Cooling Rate | Hardness | Distortion | Cracking Tendency |

|---|---|---|---|---|

| Oil | Moderate | High | Moderate | Low |

| Water | Rapid | Very high | High | High |

| Polymer | Slow | Moderate | Low | Low |

Conclusion

Heat treating O1 tool steel is a critical process for optimizing its performance. By understanding the principles of heat treating and following proper procedures, you can achieve the desired hardness, toughness, and wear resistance for your specific application.

FAQ

Can I heat treat O1 tool steel at home?

While it is possible to heat treat O1 tool steel at home, it requires specialized equipment and knowledge. It is recommended to have the process performed by a professional heat treater.

What is the difference between hardening and tempering?

Hardening increases the hardness of the steel by forming martensite, while tempering reduces the brittleness of the martensite.

How long does heat treating take?

The duration of the heat treating process depends on the size of the workpiece, the desired properties, and the equipment used.