Introduction

In modern manufacturing, the selection of materials is crucial for achieving desired product quality and performance. Among the array of materials available, M2 tool steel rods stand out for their exceptional hardness, wear resistance, and machinability. This blog explores in-depth the benefits of incorporating M2 tool steel rod into manufacturing processes, examining their properties, applications across industries, advantages, and practical considerations.

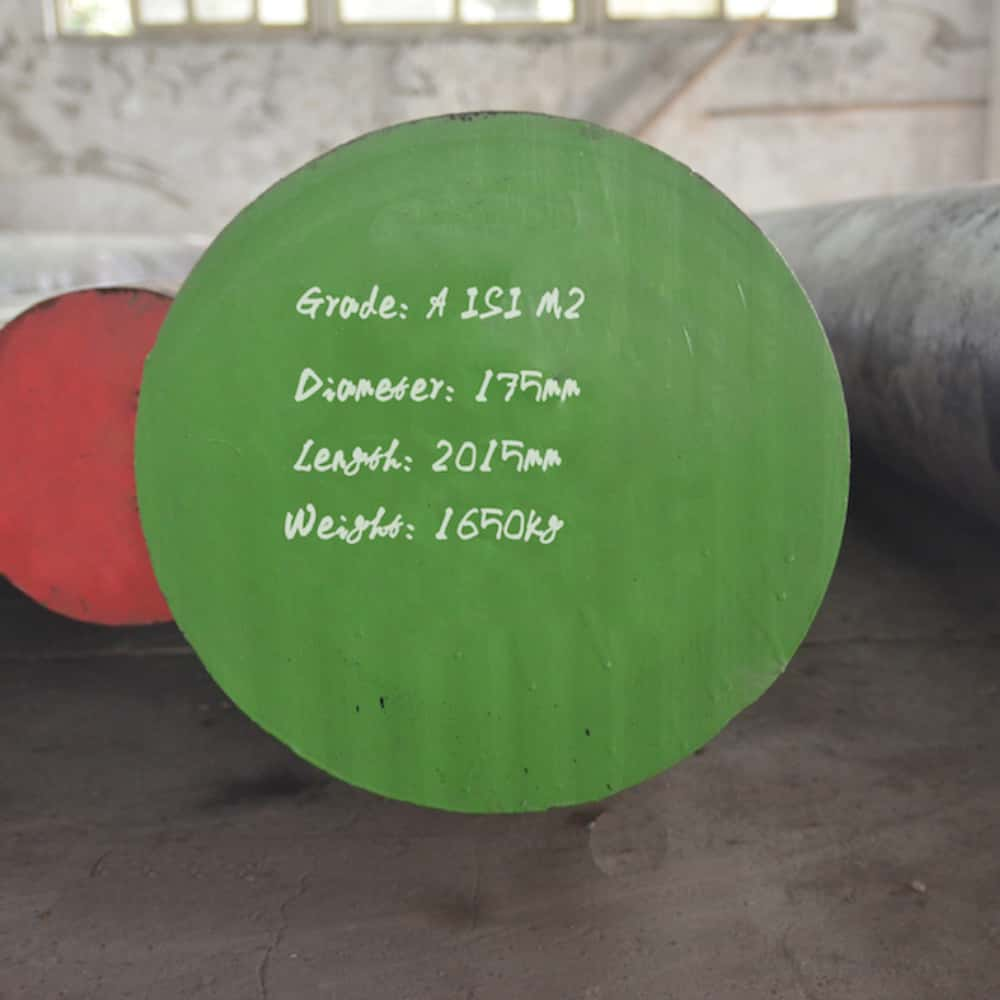

Properties of M2 Tool Steel Rods

M2 tool steel rod are renowned for their unique composition and properties. They are characterized by high carbon (0.85% – 0.95%) and tungsten (5.50% – 6.75%) content, which contribute significantly to their exceptional hardness and wear resistance. This composition allows M2 tool steel rod to achieve a hardness of approximately HRC 60-65, making them suitable for applications where high abrasive wear and cutting forces are encountered.

Their tensile strength typically ranges around 2,020 MPa (293,000 psi), with a yield strength of approximately 1,600 MPa (232,000 psi). These mechanical properties ensure that M2 tool steel rod can withstand the stresses and strains of machining operations without compromising on performance. Moreover, M2 tool steel rod exhibit good heat resistance, capable of maintaining their hardness and toughness at temperatures up to 600°C (1,112°F), which is advantageous in high-speed machining applications.

Applications of M2 Tool Steel Rods

The versatility of M2 tool steel rods lends them to a wide range of applications across various industries:

- Cutting Tools: M2 tool steel rods are extensively used for manufacturing cutting tools such as drills, taps, milling cutters, and reamers. Their high hardness and wear resistance make them ideal for cutting and machining operations where tool longevity and performance are critical.

- Machine Components: In the manufacturing of machine components, where durability and toughness are paramount, M2 tool steel rods are preferred. They are used in gears, shafts, bushings, and other components subjected to high wear and abrasion.

- Cold Work Applications: M2 tool steel rod excel in cold work applications where tools need to maintain sharp edges and endure repetitive use. They are employed in punching dies, blanking dies, and forming dies where high hardness and toughness are essential.

The adaptability of M2 tool steel rod across these diverse applications underscores their importance in modern manufacturing processes, contributing to improved efficiency and performance.

Advantages of Using M2 Tool Steel Rods

The advantages of integrating M2 tool steel rods into manufacturing operations are manifold:

- High Hardness: M2 tool steel rod are renowned for their exceptional hardness, which allows them to maintain sharp cutting edges and resist deformation under high cutting forces. This characteristic extends tool life and reduces the frequency of tool changes, thereby enhancing productivity.

- Excellent Wear Resistance: Their high tungsten content contributes to superior wear resistance, making M2 tool steel rods suitable for prolonged use in demanding machining environments. This attribute minimizes tool wear and ensures consistent performance over extended periods.

- Good Machinability: Despite their high hardness, M2 tool steel rod exhibit good machinability. They can be easily shaped, ground, and finished to precise specifications, enabling the manufacture of complex geometries and intricate parts with minimal difficulty.

- Heat Resistance: M2 tool steel rods retain their hardness and mechanical properties at elevated temperatures, making them suitable for high-speed machining operations where heat generation is significant. This capability reduces the risk of thermal degradation and ensures consistent performance under challenging conditions.

More technical details about M2 Tool Steel Bars

| Property | Value |

|---|---|

| Chemical Composition | 0.85-0.95% C, 4.75-5.50% Cr, 5.50-6.75% W, 1.75-2.50% Mo |

| Density | 7.85 g/cm³ |

| Melting Point | 1,540-1,570°C (2,804-2,858°F) |

| Modulus of Elasticity | 210 GPa |

| Poisson’s Ratio | 0.27 |

| Coefficient of Thermal Expansion | 10.6 µm/m°C |

Case Study: Manufacturing Industry Application

To illustrate the practical benefits of M2 tool steel rods, consider a case study in the automotive manufacturing sector. A company specializing in the production of engine components upgraded their cutting tools to M2 tool steel rod. The transition resulted in a substantial increase in tool life, reducing tool replacement frequency by 30% and improving machining efficiency by 20%. Moreover, the enhanced wear resistance of M2 tool steel rod led to improved surface finish and dimensional accuracy of machined parts, thereby reducing scrap and rework.

This case study highlights how the superior properties of M2 tool steel rod can translate into tangible benefits for manufacturers, enhancing productivity, reducing costs, and improving product quality.

Conclusion

In conclusion, M2 tool steel rods represent a significant advancement in materials technology for manufacturing applications requiring high hardness, wear resistance, and machinability. Their unique properties make them indispensable in industries ranging from aerospace and automotive to general machining and toolmaking. By leveraging M2 tool steel rods, manufacturers can achieve superior performance, extend tool life, and optimize production processes.

The strategic adoption of M2 tool steel rods not only enhances operational efficiency but also strengthens competitiveness in today’s dynamic manufacturing landscape. As industries continue to evolve, the demand for advanced materials like M2 tool steel rods will continue to grow, driving innovation and excellence in manufacturing practices.

FAQ

Q: What are M2 tool steel rods used for?

A: M2 tool steel rods are primarily used in manufacturing cutting tools such as drills, taps, milling cutters, and reamers due to their high hardness and wear resistance.

Q: How do M2 tool steel rods compare to other tool steels?

A: M2 tool steel rods are distinguished by their superior hardness, wear resistance, and machinability compared to many other tool steels. They excel in high-speed machining applications.

Q: Can M2 tool steel rods withstand high temperatures?

A: Yes, M2 tool steel rods exhibit good heat resistance, maintaining their properties at temperatures up to 600°C (1,112°F), which is advantageous in demanding machining environments.