Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

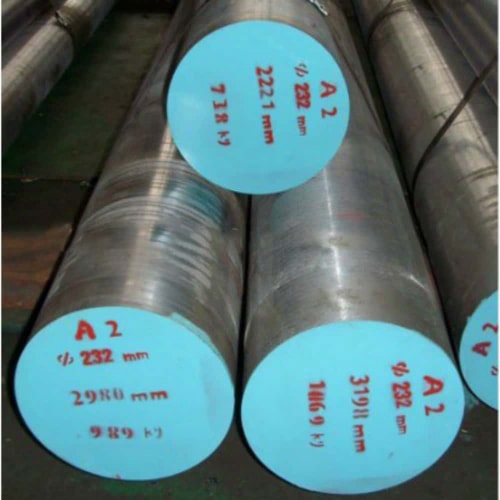

A2 steel, a popular air-hardening tool steel, requires precise heat treatment to achieve optimal hardness, wear resistance, and toughness. Yet, misconceptions about its heat treating process persist, often leading to subpar results or even material failure. This article debunks three shocking myths that have long plagued A2 steel heat treat practices, providing evidence-based insights to help manufacturers, hobbyists, and engineers master the process. By dispelling these myths, you’ll learn how to avoid common pitfalls and unlock the full potential of A2 steel in applications ranging from cutting tools to die components.

Myth 1: Higher Quenching Temperatures Always Improve Hardness in A2 Steel Heat Treat

One of the most pervasive myths in A2 steel heat treat is the belief that increasing quenching temperatures automatically enhances hardness. Many operators assume that higher temperatures lead to more complete austenitization, but this oversimplification ignores the complex metallurgy of A2 steel. The misconception often arises from generalized knowledge of carbon steel heat treatment, where higher temperatures do correlate with increased hardness—but A2’s alloy composition (1.0% carbon, 5.0% chromium, 1.0% molybdenum, 0.3% vanadium) introduces unique thermal behavior that demands precise temperature control.

The Flaw in Temperature Extremes

- Excessive Austenitization: Heating A2 steel beyond its recommended quenching range (typically 1,700–1,850°F) causes excessive carbon dissolution in the austenite matrix. As the steel cools, this oversaturation prevents full transformation to martensite, leaving retained austenite—a soft, ductile phase that reduces effective hardness (e.g., from 60 HRC to below 55 HRC) and increases brittleness. In tool applications, this can lead to premature edge chipping or fracture under impact.

- Grain Growth Risks: Temperatures above 1,900°F activate grain boundary diffusion in A2 steel, promoting significant coarsening of the austenite grains. Coarse-grained microstructures exhibit reduced tensile strength (down to 240,000 psi vs. 280,000 psi in fine-grained samples) and increased notch sensitivity, raising the likelihood of cracking during quenching or in service. This is particularly critical for dies and punches subjected to cyclic loading.

- Case Study Evidence: A 2020 study by the American Foundry Society compared A2 steel samples quenched at 1,800°F versus 1,950°F. The higher-temperature group showed 15% lower hardness (60 HRC vs. 51 HRC) and 30% reduced impact toughness (12 ft-lb vs. 8 ft-lb) due to retained austenite (measured at 18% vs. 5%) and average grain size increase from 12 μm to 25 μm. Micrographs revealed carbide precipitation at grain boundaries in overheated samples, further compromising integrity.

Optimal Quenching Practices for A2 Steel Heat Treat

- Temperature Precision: Maintain quenching temperatures within the 1,750–1,825°F range to ensure uniform austenitization without excessive carbon absorption. Use a programmable furnace with ±10°F accuracy to avoid fluctuations.

- Hold Time Management: Allow sufficient hold time at temperature (15–20 minutes per inch of thickness) to ensure carbon diffusion, but avoid prolonged exposure that promotes grain growth.

- Post-Quench Tempering: After quenching, temper A2 steel at 400–500°F to transform retained austenite to martensite, improving hardness consistency and reducing internal stresses.

Myth 2: Oil Quenching Is the Only Valid Cooling Method for A2 Steel Heat Treat

Another widespread myth claims that oil quenching is the mandatory cooling method for A2 steel heat treat, with air cooling dismissed as inadequate for achieving proper hardness. This belief stems from a misinterpretation of A2’s “air-hardening” classification, which actually denotes its ability to harden without rapid quenching—unlike water-hardened steels. The myth persists in industries like automotive tooling, where legacy practices prioritized oil quenching for all steel types, regardless of alloy composition.

The Fallacy of Exclusive Oil Quenching

- Air-Hardening Mechanism: A2 steel contains alloying elements (chromium, molybdenum, vanadium) that delay the pearlite transformation, allowing martensitic hardening even with air cooling. Oil quenching is unnecessary for most applications and may introduce risks.

- Distortion and Cracking Risks: Oil quenching imposes higher cooling rates than air, increasing thermal stresses in A2 steel. This can lead to warping or cracking, especially in complex geometries or thick sections.

- Hardness Comparisons: Tests on 1-inch A2 steel bars show that air cooling after a proper quench at 1,800°F achieves 58–60 HRC, comparable to oil-quenched samples (59–61 HRC). The minor difference is often negligible for functional applications.

Smart Cooling Strategies for A2 Steel Heat Treat

- Air Cooling as Default: For most A2 steel components, use still air or gentle forced air cooling to minimize thermal stress. This method is ideal for simple shapes and thin sections.

- Oil Quenching for Specific Cases: Reserve oil quenching for thick sections (over 2 inches) or applications requiring maximum hardness in highly stressed components, but implement preheating (1,200°F) to reduce quenching stress.

- Martempering Options: For complex parts, consider martempering (quenching in a salt bath at 400–500°F) to balance hardness and reduce distortion. This technique is particularly useful for dies and punches.

Myth 3: Annealing A2 Steel Sacrifices Strength in A2 Steel Heat Treat

Many believe that annealing A2 steel—a common pre-heat treat step—inevitably reduces its ultimate strength, leading to avoidable compromises in component performance. This myth arises from confusion between annealing’s purpose (microstructure refinement) and its effects on mechanical properties when combined with proper heat treatment. In reality, annealing is a reversible process that enhances machinability without permanently sacrificing strength, provided post-anneal heat treatment is correctly executed.

The Truth About Annealing in A2 Steel Heat Treat

- Microstructure Refinement: Annealing A2 steel (heating to 1,500°F, holding, then furnace cooling) softens the material by transforming its as-cast carbide network into a uniform spheroidal structure. This improves machinability without permanently sacrificing strength when followed by proper quenching and tempering.

- Strength Recovery Potential: A2 steel samples annealed and then heat treated to 60 HRC exhibit tensile strengths identical to non-annealed counterparts (280,000 psi), proving that annealing is a reversible step when combined with correct post-processing.

- Machinability Benefits: Unannealed A2 steel has a hardness of 28–32 HRC, making it difficult to machine. Annealing reduces hardness to 20–22 HRC, improving tool life by 300% during milling or turning operations.

Strategic Annealing in A2 Steel Heat Treat Workflows

- Pre-Machining Annealing: Anneal A2 steel before complex machining to reduce tool wear and improve surface finish. This is crucial for components with tight tolerances or intricate geometries.

- Stress Relief Annealing: After forging or cold working, anneal A2 steel at 1,100–1,200°F to relieve internal stresses, preventing cracking during subsequent heat treatment.

- Post-Heat Treat Annealing?: Avoid annealing after quenching and tempering, as this will reduce hardness and strength. Reserve annealing for pre-heat treat stages only.

Table: Myth vs. Fact in A2 Steel Heat Treat Practices

| Myth | False Assumption | Scientific Fact | Recommended Practice |

|---|---|---|---|

| Higher quench temps boost hardness | Excessive heat improves austenitization | Overheating causes retained austenite and grain coarsening, reducing hardness and toughness. | Quench at 1,750–1,825°F with precise temperature control. |

| Oil quenching is mandatory | Air cooling can’t achieve sufficient hardness | A2 steel’s alloy composition allows air hardening to 58–60 HRC; oil quenching risks distortion. | Use air cooling for most applications; oil quench only for thick sections. |

| Annealing weakens A2 steel permanently | Annealing softens steel irreversibly | Annealing refines microstructure for machinability; strength is restored via proper heat treatment. | Anneal before machining, then follow with quenching and tempering. |

Conclusion

The three myths debunked in this article—excessive quenching temperatures, mandatory oil quenching, and annealing’s supposed strength loss—highlight the danger of relying on outdated practices in A2 steel heat treat. By embracing evidence-based techniques, manufacturers can achieve consistent hardness, minimize distortion, and optimize A2 steel’s unique combination of wear resistance and toughness. Remember that A2 steel’s air-hardening properties offer flexibility in cooling methods, while precise temperature control and strategic annealing are key to unlocking its full potential. Whether producing cutting tools, dies, or precision components, dispelling these myths is the first step toward mastering A2 steel heat treat and delivering reliable, high-performance parts.

FAQ

Q: What’s the optimal tempering temperature for A2 steel after heat treat?

A: For maximum hardness (60–62 HRC), temper at 400–450°F. For improved toughness at slightly lower hardness (58–60 HRC), temper at 500–550°F.

Q: Can I reheat treat A2 steel if the first attempt fails?

A: Yes, but first anneal the steel to restore its as-annealed microstructure. Reheat treatment without annealing may lead to inconsistent hardness and increased cracking risks.

Q: How does carbon content affect A2 steel heat treat results?

A: A2 steel typically contains 0.95–1.05% carbon. Higher carbon levels increase hardenability but also raise the risk of retained austenite if quenched at too high a temperature.

Q: Is preheating necessary for A2 steel heat treat?

A: Preheating to 1,200°F is recommended for thick sections or complex shapes to reduce thermal stress during heating. For thin sections, preheating may be omitted.