Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Blog Key Points

- Introduction to S‑7 tool steel and why it matters

- Detailed material properties with engineering data

- Industrial applications and impact performance insights

- Comparisons with other steels (D2, A2, 4140)

- Heat treatment and processing best practices

- Real‑world expert observations on machining and use

- Design and engineering considerations

- Maintenance, safety, and cost factors

- FAQ section addressing common search intents

Introduction

S‑7 tool steel has earned a strong reputation among engineers, toolmakers, and manufacturing professionals for its exceptional shock resistance, toughness, and durability in demanding environments. Unlike many steels optimized solely for wear resistance or hardness, this grade delivers the resilience needed where repetitive impact, sudden loading, and cyclic shock conditions are common. For high‑impact tools like hammers, punches, shear blades, and forging dies, S‑7 strikes an ideal balance — resisting fracture while maintaining performance under stress. This article dives deep into what makes this alloy stand out, supported by authoritative data and real industry insights.

Understanding the Material: What Is S‑7 Tool Steel?

Material Classification and Composition

S‑7 is classified within the “S series” of shock‑resisting tool steels, defined by the American Iron and Steel Institute (AISI) and widely standardized across ASTM and DIN systems (≈ 1.2355). Its balanced chemical makeup gives it high impact strength with moderate wear resistance — a trade‑off critical for shock‑intensive applications.

Typical Composition (nominal):

- Carbon (C): 0.45 – 0.55%

- Chromium (Cr): 3.00 – 3.50%

- Molybdenum (Mo): 1.30 – 1.80%

- Manganese (Mn): 0.20 – 0.80%

- Silicon (Si): 0.20 – 1.00%

- Vanadium (V): 0.20 – 0.30%

(Balance is iron)

These alloying elements provide a mix of toughness, hardenability, and dimensional stability post‑heat treatment.

Key Mechanical Properties

| Property | Typical Value |

|---|---|

| Density | ~7.83 g/cm³ |

| Modulus of Elasticity | ~207 GPa |

| Annealed Hardness | ~200–240 HB (~18–24 HRC) |

| Hardened & Tempered Hardness | 50–58 HRC (commonly 52–57 HRC) |

| Tensile Strength (Hardened) | ~900–1100 MPa |

| Impact Toughness | High (Charpy > 20–60 J) |

| Machinability (Annealed) | ~70–75% of 1% carbon steel |

These properties illustrate S‑7’s ability to withstand heavy loads, absorb energy without cracking, and retain structural integrity after heat treating — traits vital for impact tools.

What Makes S‑7 Steel Ideal for Impact Tools?

Shock & Impact Resistance

The most defining trait of S‑7 tool steel is its ability to withstand repeated impacts without catastrophic failure. It absorbs and redistribates shock energy better than many high‑hardness steels, reducing micro‑cracking or sudden breakage.

This makes it a preferred choice for:

- Hammers, chisels, and punches where repetitive blows are expected

- Shear blades and dies that face intermittent high‑force cycles

- Forging and swaging tools where shock loads are inherent

Balanced Hardness and Toughness

While S‑7 can achieve 50–58 HRC hardness after quenching and tempering, it maintains exceptional toughness compared to high‑carbon, high‑chromium steels that become brittle at similar hardness levels. This balance prevents premature tool failure in impact scenarios.

Dimensional Stability

S‑7’s air‑hardening response reduces distortion during heat treatment, making it suitable for precise components where geometric accuracy after hardening is crucial — a significant advantage over water‑ or oil‑quenched tool steels.

Industrial Use Cases: What Applications Benefit Most?

Heavy‑Duty Hand Tools

Tools such as hammer heads, cold chisels, and punches benefit from S‑7’s shock‑resisting nature — absorbing impact without losing shape or cracking. These tools typically operate under high dynamic loads, where both toughness and fatigue resistance matter.

Cold Work Dies

Shear and blanking dies used in metal forming industries experience sharp, repetitive impact forces. S‑7’s resilience against notched impact loads helps extend die life and reduce downtime due to frequent breakages.

Medium Run Forging Components

In forging operations where dies are reused and repeatedly struck, the steel’s combination of hardness and toughness ensures longevity and reliability, particularly in production environments.

Tool and Die Prototyping

Prototyping for heavy‑duty tools often leverages S‑7 because it provides realistic performance outcomes without extreme brittleness, giving engineering teams a reliable baseline for durability testing.

Benchmarking S‑7 Tool Steel Against Other Grades

S‑7 vs D2 Tool Steel

- S‑7: High impact resistance, moderate wear resistance, avoids brittleness.

- D2: Exceptional wear resistance due to higher chromium and carbides but more brittle under impact.

Use Case Insight: S‑7 is preferred for shock tools (e.g., chisels), whereas D2 excels in cutting tools and wear‑intensive dies.

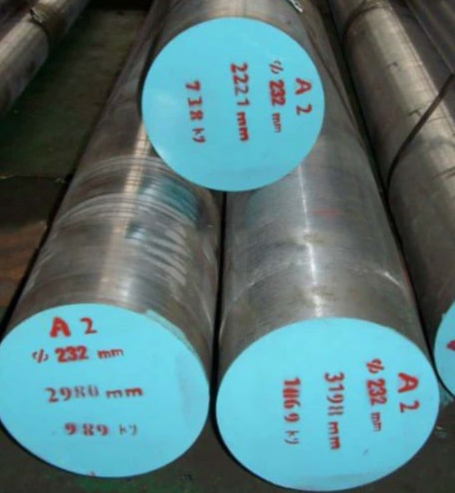

S‑7 vs A2 Tool Steel

- S‑7: Specialized for shock loads, retains toughness.

- A2: Air hardening, versatile with good wear resistance, slightly less shock tolerant than S‑7.

Design Takeaway: S‑7 fits impact tools; A2 may be a better choice when wear resistance is equally important as toughness.

S‑7 vs 4140 Alloy Steel

4140 is a versatile alloy steel capable of decent strength and toughness after heat treating, but generally lacks the shock absorption and air‑hardening consistency of S‑7, making the latter more predictable in high‑impact tooling.

Heat Treatment & Processing Best Practices

Annealing for Machinability

Annealing S‑7 to approximately 200–240 HB (~18–24 HRC) makes it easier to machine with standard tooling while reducing stress prior to final hardening.

Hardening and Tempering

After austenitizing at recommended temperatures, S‑7 is air cooled and then tempered to achieve targeted hardness. Optimal tempering (400–450 °F / 204–232 °C) results in 50–58 HRC, balancing toughness and strength.

Too high a final hardness (e.g., approaching 60+ HRC) can significantly reduce impact toughness and should be avoided in shock tool applications to prevent premature failures.

Additional Treatments

Surface hardening (like nitriding) can boost surface wear resistance to ~64 HRC, but may compromise underlying shock resistance — a trade‑off that should be assessed per application.

Machining & Fabrication Insights from Industry Pros

Professional machinists often note that S‑7 in its hardened state (50–58 HRC) typically requires specialized tooling (e.g., coated carbide or CBN) for effective milling or turning, especially when dimensional tolerances are tight. Pre‑hardening machining after annealing is recommended. Practical experience shows that interrupted cuts can thermally shock inserts — adjusting feed and speed accordingly improves tool life and surface finish. *

(*Community users discuss machining hardness ranges and tooling adjustments for S‑7, reinforcing the need for proper planning in production environments.)

Design Considerations When Choosing S‑7 Steel

Shock Load Profiles

Understanding the magnitude and frequency of impact forces is critical. Where repetitive, high‑energy impacts occur, S‑7’s toughness reduces crack propagation and catastrophic fractures.

Section Thickness and Hardness

Thicker tool sections may benefit from controlled hardening cycles with longer soak times to ensure uniform hardness and reduce residual stresses.

Operating Temperatures

While primarily a cold‑work tool steel, S‑7 performs satisfactorily under moderate elevated temperatures when tempered appropriately, maintaining useful mechanical properties in varied environments.

Maintenance, Safety & Cost Factors

Tool Maintenance

Regular inspection for chipping, micro‑cracks, and deformation extends service life. Correct storage and shielding from corrosion also contribute to long‑term performance.

Safety Considerations

Due to its hardness, improper heat treating or machining can introduce brittle zones — emphasizing the need for controlled heat treatments and experienced metallurgists.

Cost vs. Lifecycle Value

Although S‑7 may be priced higher than basic alloy steels, its extended life under impact conditions often yields lower total cost of ownership for shock‑intensive tooling.

FAQ

What makes S‑7 tool steel better for impact tools?

Its unique alloy balance and air‑hardening response provide high shock resistance and toughness, preventing fractures under repeated impacts common in heavy‑duty tools.

Can S‑7 be used for cutting tools?

While possible, steels like D2 or high‑speed steels often outperform S‑7 in pure cutting applications due to higher wear resistance.

How hard should S‑7 be hardened for impact applications?

Tempered hardness of 50–58 HRC typically gives the best balance between toughness and strength for impact tools.

Is S‑7 tool steel machinable?

Yes — especially in annealed condition — but hard machining after heat treatment may require specialized tools (e.g., carbide, CBN) and adjusted feeds/speeds.

What are common applications of S‑7 tool steel?

It’s widely used for punches, shear blades, forging dies, cold work tools, and impact components due to its toughness and shock‑resisting nature.