Plastic Mold Steel

High-Quality Molding Solutions

Introduction To Plastic Mold Steel

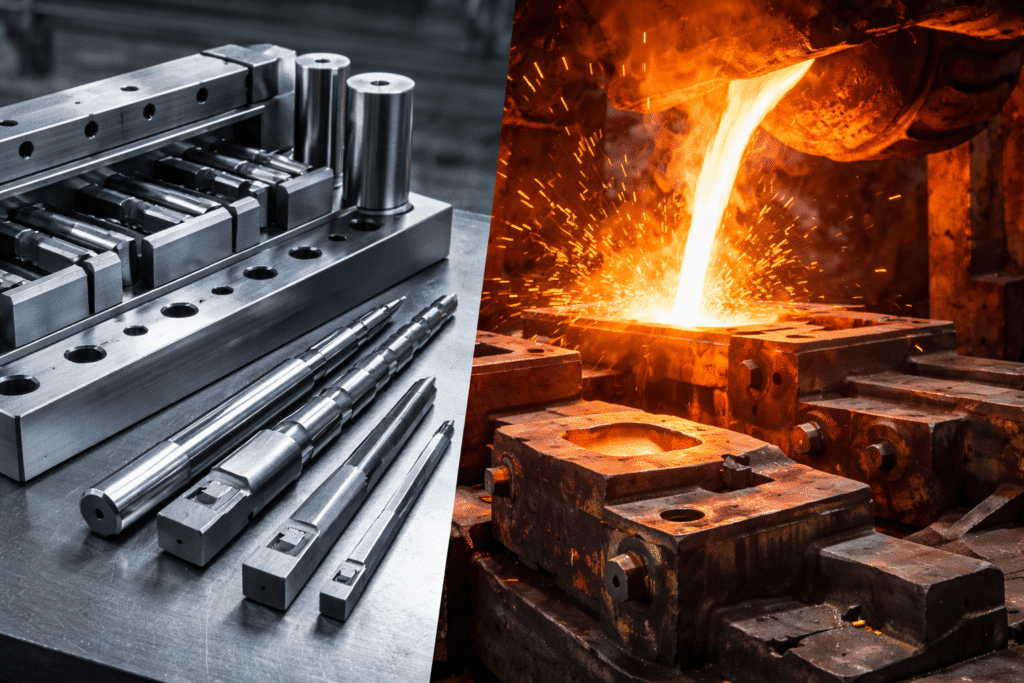

Plastic mold steel is a special steel used to make plastic molds, and is widely used in plastic molding processes such as injection molding, extrusion, and blow molding. Plastic mold steel has excellent wear resistance, corrosion resistance, and good processability, making it an ideal choice for high-performance plastic molds.

Key Features Of Plastic Mold Steel

Excellent Wear Resistance

Plastic mold steel can maintain the stability and precision of the mold after long-term use, reducing the risk of mold damage.

Good Corrosion Resistance

With strong corrosion resistance, it is particularly suitable for handling plastics that contain chemicals.

Superior Machinability

Plastic mold steel is easy to process and heat treat, and can maintain precision and stability during the manufacturing process.

High Strength And Hardness

Plastic mold steel can withstand high pressure and high temperature working environment and is suitable for high-demand plastic molds.

Heat Treatment Properties

This steel can be heat treated during processing to increase its hardness and wear resistance.

Applications Of Plastic Mold Steel

Plastic mold steel is widely used across various fields, especially in the production of plastic products. Below are some common applications:

Injection Molds

Plastic mold steel is the ideal choice for injection molds, ensuring mold stability under high temperatures and high pressure.

Precision Plastic Products

Used to manufacture high-precision plastic products, such as electronic device housings and automotive components.

Hot Runner Molds

High-speed tool steels like H13 are commonly used for hot runner molds to enhance production efficiency and product quality.

Blow Molding Molds

Suitable for molds used to create large plastic containers, bottles, and similar products.

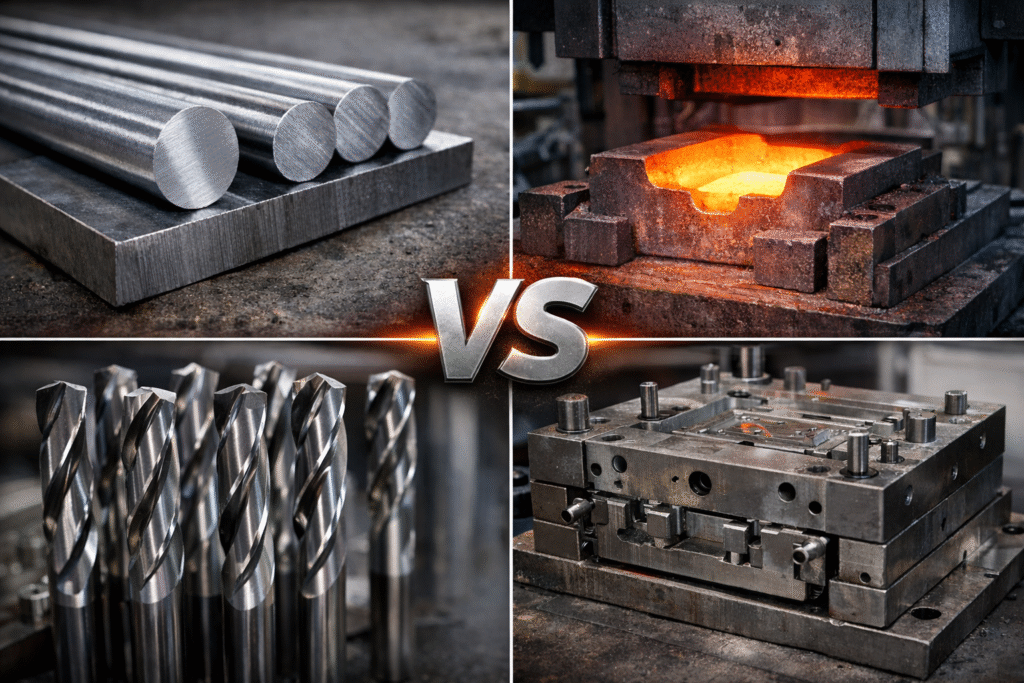

Common Types Of Plastic Mold Steel

Plastic mold steel comes in various types depending on application requirements. Below are some common types of plastic mold steel:

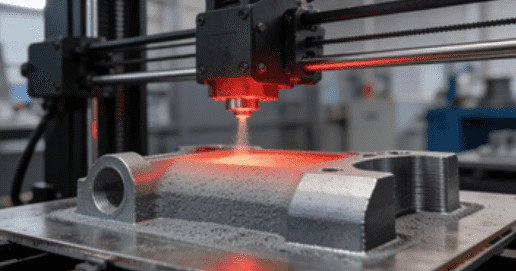

Why Choose Qilu For Plastic Mold Steel?

At Qilu, we provide high-quality plastic mold steel to meet the needs of different customers. We are well aware of the special requirements of mold steel for various applications, so our products can provide you with excellent performance and long-term durability. We strictly control quality to ensure that each batch of products meets industry standards, and at the same time provide customized solutions to meet the needs of different fields. Regardless of the size of the order, we can ensure timely delivery and provide competitive prices by optimizing the production process to ensure that customers get cost-effective products.

FAQ

You May Also Be Interested In

P20/1.2311

Round Bar:

diameter 200mm–1000mm

Steel Plate:

thickness 16-100mm x width 200-2000mm

Another dimension according to your requirements Surface condition:

— Black, annealed Rough Machined, Turned, or as per given requirements.

| Element | P20 | 1.2311 |

|---|---|---|

| C | 0.28-0.4 | 0.35-0.45 |

| Mn | 0.6-1.0 | 1.3-1.6 |

| P | 0.03max | 0.03max |

| S | 0.03max | 0.05-0.1 |

| Si | 0.2-0.8 | 0.2-0.4 |

| Cr | 1.4-2.0 | 1.8-2.1 |

| Mo | 0.3-0.55 | 0.15-0.25 |

Heat Treatment

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Applications

P20 tool steels are used for low temperature applications that include injection molds and die casting dies. Main applications of P20 steel plate and bar:

Plastic moulds, die holder, backers, rames for plastic pressure dies, hydro forming mold tools.bolsters, die holders. Also suitable for other applications such as rails, shafts and wear strips.

M35/1.3243

M35 Steel Round Bar:

diameter 2mm–300mm

M35 Steel Plate:

thickness 2-200mm x width 200-610mm

Another dimension according to your requirements Surface condition:

— Black, annealed Rough Machined, Turned, or as per given requirements.

| Element | M35 | 1.3243 |

|---|---|---|

| C | 0.82-0.95 | 0.87-0.95 |

| Mn | 0.15-0.40 | 0.4max |

| P | 0.03max | 0.03max |

| S | 0.03max | 0.03max |

| Si | 0.2-0.45 | 0.45max |

| Cr | 3.8-4.5 | 3.8-4.5 |

| V | 1.75-2.15 | 1.7-2.1 |

| Mo | 4.75-5.25 | 4.7-5.2 |

| W | 5.5-6.5 | 5.9-6.7 |

| Co | 4.6-5.0 | 4.5-5.0 |

Heat Treatment

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Applications

M35 steel is usually used in conditions with the demand for high hardness. M35 steel is suitable for cutting tools such as cutting tools including broaches, milling cutters, reamers, end mills and saw blades. It is also a good quality wear resistant HSS grade for cold work area. Steel M35 is also suitable for cold work applications, where exacting demands are imposed on wear resistance. The steel possesses an admirable combination of wear resistance and toughness and in these respects superior to the high alloyed cold work steels.

M42/1.3247

M42 Steel Round Bar:

diameter 2mm–200mm

M42 Steel Plate:

thickness 2-200mm x width 200-610mm

Another dimension according to your requirements Surface condition:

— Black, annealed Rough Machined, Turned, or as per given requirements.

| Element | M42 | 1.3247 |

|---|---|---|

| C | 1.05-1.15 | 1.05-1.15 |

| Mn | 0.15-0.40 | – |

| P | 0.03max | 0.7max |

| S | 0.03max | 0.03max |

| Si | 0.15-0.65 | – |

| Cr | 3.50-4.25 | 3.5-4.5 |

| V | 0.95-1.35 | 0.90-1.30 |

| Mo | 9.0-10.0 | 9.0-10.0 |

| W | 1.15-1.85 | 1.2-1.9 |

| Co | 7.75-8.75 | 7.5-8.5 |

Heat Treatment

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Applications

M42 steel is a high-speed steel suitable for cutting tools such as, twist drills, broaches, taps, milling, cutters, saws, reamers etc. In terms of performance, HSS grade M42 is a steel to be used in conditions where the demand for hot hardness is of great importance i.e. where high performance is essential.

Typically employed to machine the super alloys and exotic, AISI HSS M42 tool steel is employed in drills, hobs, taps, end mills, milling cutters, form and gear cutters, broaches and chasers.

M3

Another dimension according to your requirements Surface condition:

— Black, annealed Rough Machined, Turned, or as per given requirements.

| Element | M3 |

|---|---|

| C | 1.15-1.25 |

| Mn | 0.15-0.40 |

| P | 0.03max |

| S | 0.03max |

| Si | 0.2-0.45 |

| Cr | 3.75-4.50 |

| V | 2.75-3.75 |

| Mo | 4.75-6.5 |

| W | 5.00-6.75 |

| Ni | 0.3max |

Heat Treatment

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Applications

M3 Class 2 molybdenum high speed tool steels are used in the production of taps, broaches, end mills, milling cutters and reamers.

M4

Another dimension according to your requirements Surface condition:

— Black, annealed Rough Machined, Turned, or as per given requirements.

| Element | M4 |

|---|---|

| C | 1.25-1.40 |

| Mn | 0.15-0.40 |

| P | 0.03max |

| S | 0.03max |

| Si | 0.2-0.45 |

| Cr | 3.75-4.75 |

| V | 3.75-4.50 |

| Mo | 4.25-5.5 |

| W | 5.25-6.5 |

| Ni | 0.3max |

Heat Treatment

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Applications

M4 molybdenum high-speed tool steels are suitable for all types of cutting tools used in machining operations.

M7

Another dimension according to your requirements Surface condition:

— Black, annealed Rough Machined, Turned, or as per given requirements.

| Element | M7 |

|---|---|

| C | 0.84-1.05 |

| Mn | 0.1-0.4 |

| P | 0.03max |

| S | 0.03max |

| Si | 0.2-0.45 |

| Cr | 3.75-4.50 |

| V | 1.8-2.2 |

| Mo | 7.75-8.50 |

| Cu | 0.25max |

| Ni | 0.3max |

Heat Treatment

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Applications

M7 molybdenum high-speed tool steels are mainly used for cutting tools in all machining operations.

Company Profile

Qilu Steel is a leading supplier of high-quality tool steel with extensive experience in the industry. Our investment in a specialized factory further demonstrates our commitment to being at the forefront of the tool steel industry. We offer a wide range of tool steel grades, including P20, H13, D2, and S7, each with unique properties suited for different applications.