Hot Work Tool Steel

Cope with extreme temperatures and create excellent durability

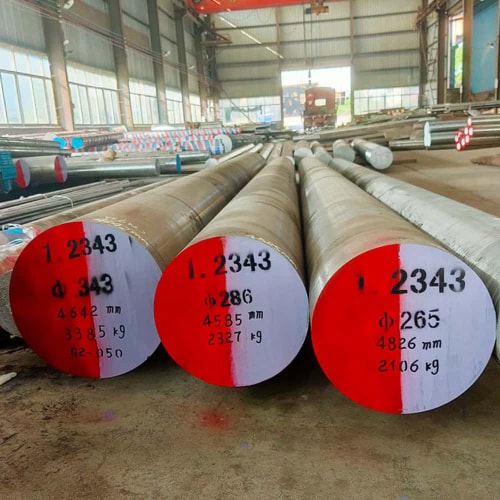

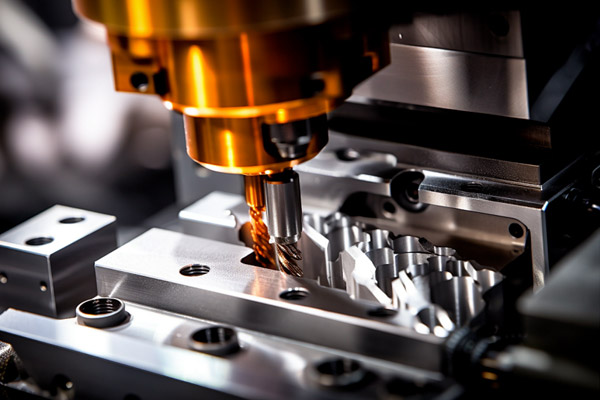

Introduction To Hot Work Tool Steel

Hot work tool steel (HWS) is a type of steel designed to withstand high temperature working environments. It has excellent heat resistance, wear resistance and good toughness, making it an ideal choice for high temperature processes such as casting, forging and stamping. Whether in the field of metal processing or mold making, hot work tool steel can withstand extreme working conditions and ensure long-term stable operation of the tool.

Key Features Of Hot Work Tool Steel

Excellent Heat Resistance

Hot work tool steel can maintain its hardness and strength at extremely high temperatures, making it suitable for high temperature environments such as casting and forging.

Excellent Wear Resistance

The steel has excellent resistance to wear and tear and can maintain a long service life even at high temperatures.

High Toughness And Impact Resistance

Hot work tool steel has very high toughness and can withstand severe impact loads without breaking or damage.

Thermal Fatigue Resistance

After repeated heating and cooling at high temperatures, hot work tool steel can still maintain good performance and avoid premature failure.

Excellent Processing Performance

Under proper heat treatment, hot work tool steel can be finely processed to meet different tool and mold requirements.

Applications Of Cold Work Tool Steel

Hot working tool steel is widely used in working places under high temperature environment, especially in the following fields:

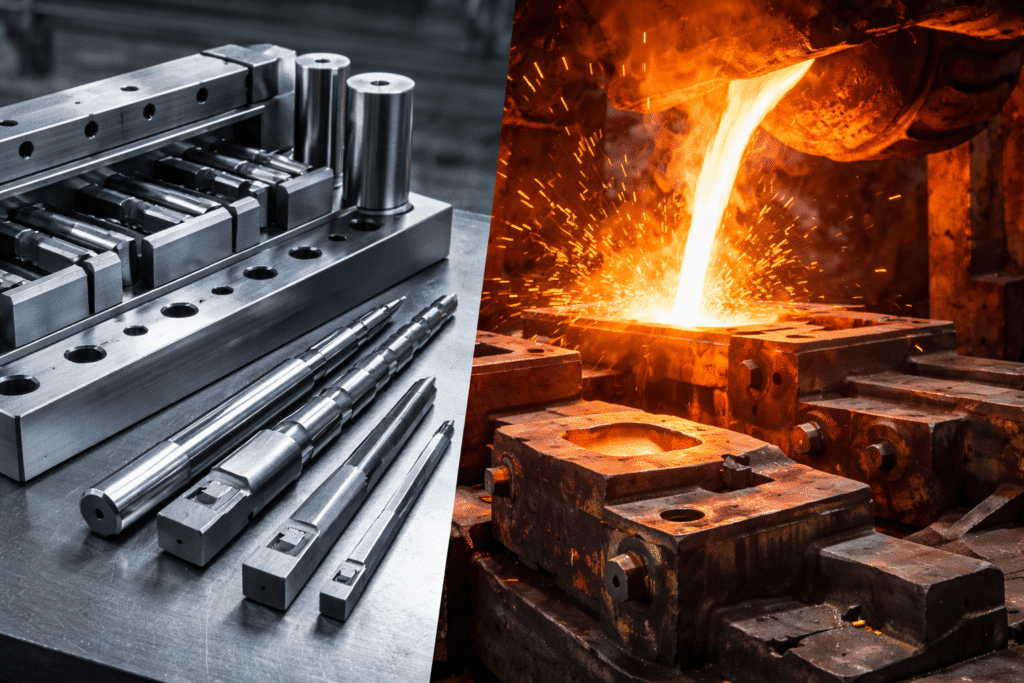

Casting

In the metal casting process, hot work tool steel is used in the manufacture of molds and castings due to its excellent high temperature resistance.

Forging

In forging operations, hot work tool steel can withstand high temperatures and huge pressures to ensure the durability of the tool.

Stamping

Hot work tool steel is also commonly used in the manufacture of stamping dies, which can perform stamping tasks efficiently at high temperatures.

Mold Manufacturing

Used to make high wear-resistant and high temperature resistant precision molds, suitable for processing materials such as aluminum alloys and copper alloys.

Types Of Cold Work Tool Steel

There are several grades of hot work tool steel, each with different performance characteristics, depending on the application requirements. Common types of hot work tool steel include:

Why Choose Qilu For Hot Work Tool Steel?

At Qilu, our hot work tool steel products undergo rigorous quality control and testing to ensure that each batch meets the highest industrial standards. Our products provide excellent performance and reliability for various high temperature processes, which can greatly improve production efficiency.