Table of Contents

Introduction

In the intricate world of manufacturing and craftsmanship, the choice of material is paramount to the success and longevity of tools. Among the myriad options, o1 tool steel (also known as 1.2510) stands out as a high-performance oil-hardening tool steel, highly regarded for its exceptional combination of toughness, wear resistance, and ease of heat treatment. This versatility makes o1 tool steel an indispensable choice for a wide array of cold work applications, especially where precise dimensions and a long tool life are critical. From the automotive and aerospace sectors to general tooling, o1 tool steel provides a reliable balance of these essential characteristics, ensuring precision, durability, and consistent performance.

The appeal of o1 tool steel extends to its ability to be oil-hardened, a process that, when executed correctly, can achieve a remarkable hardness typically ranging between 55-62 HRC. This specific hardness range is a testament to the steel’s robust nature, making it highly suitable for tools that demand sustained sharpness and the capacity to resist wear under moderate to high stress. Its widespread use in cold working applications, such as forming dies, punches, and blanking dies, is due to its impressive wear resistance and toughness, allowing it to endure the repetitive stresses of metal forming.

Beyond industrial applications, o1 tool steel is also a popular choice among hobbyists and custom tool makers, valued for its machinability and its capacity to produce strong, sharp edges that resist dulling. The material’s overall excellent performance, combined with its relatively affordable price, makes o1 tool steel a popular and cost-effective solution for numerous tool-making requirements. The excellent machinability of o1 tool steel, coupled with its dimensional stability after quenching, good cutting edge retention, and high surface hardness and toughness post-heat treatment, contributes to good tool life and production economy. Its high manganese content is also key to good dimensional stability during quenching.

Understanding the Properties of o1 tool steel

To truly appreciate the capabilities of o1 tool steel, a deeper understanding of its chemical composition and mechanical properties is essential. These foundational elements dictate its behavior during various processes, including heat treatment, and define its suitability for specific applications.

Chemical Composition of o1 tool steel

The chemical makeup of o1 tool steel is meticulously balanced to impart its characteristic properties. While there can be slight variations between specific grades, the general composition is crucial for its performance. The high carbon content, for instance, is primarily responsible for the steel’s ability to achieve high hardness through heat treatment. Manganese plays a significant role in providing good dimensional stability during quenching. Chromium contributes to wear resistance, and tungsten and vanadium further enhance its properties.

| Element | O1 Content (%) | 1.2510 Content (%) | Content (%) |

| C | 0.85-1.0 | 0.9-1.05 | 0.85 – 1.00 |

| Si | 1.0-1.4 | 1.0-1.2 | 0.50 |

| Mn | 0.03max | 0.03max | 1.00 – 1.40 |

| S | 0.03max | 0.03max | 0.03 |

| P | 0.1-0.5 | 0.05-0.35 | 0.03 |

| Cr | 0.4-0.7 | 0.5-0.7 | 0.40 – 0.60 |

| V | 0.3max | 0.05-0.15 | 0.30 |

| W | 0.4-0.6 | 0.5-0.7 | 0.40 – 0.60 |

| Ni | – | – | 0.30 |

| Cu | – | – | 0.25 |

Note: The table above provides general ranges for the chemical composition of o1 tool steel, which may vary slightly by standard or manufacturer. For instance, some sources indicate a higher manganese content for o1 tool steel, such as 1.00-1.40%.

Mechanical Properties of o1 tool steel

The mechanical properties of o1 tool steel are a key indicator of its suitability for various demanding applications. Its working hardness typically falls within the range of 592-658 BHN, which translates to 57-62 HRC.

Key mechanical properties for o1 tool steel include

- Tensile Strength: Approximately 111.6 KSI.

- Yield Strength: Ranges between 56.6 – 74 KSI (390 – 510 MPa). Some sources also list mechanical properties for 1.2510 as a tensile strength of ≥153 MPa and a yield strength of ≥982 MPa.

- Elongation: 41% for 1.2510.

- Reduction Area Z: 42% for 1.2510.

- Charpy Impact: 22 J for 1.2510.

- Modulus of Elasticity (Young’s Modulus): 31000 KSI, or 193 GPa (28000 ksi) when hardened to 62 HRC. This can vary with temperature, for example, 186 GPa (27000 ksi) at 191°C and 172 GPa (25000 ksi) at 399°C, still hardened to 62 HRC.

- Compressive Yield Strength (0.2% offset): Varies significantly with hardness, from 1350 MPa (196000 psi) at 50 HRC to 2200 MPa (319000 psi) at 62 HRC.

- Density: Typically 0.283 lb/in³ (7.83g/cm³).

- Thermal Conductivity: 33.0 W/(m*K) at room temperature.

- Specific Heat Capacity: 0.46 J/g-°C (0.109 BTU/lb-°F).

- Brinell Hardness (soft annealed): 190.

- Rockwell C Hardness (tempered 149-649°C): 34.0-64.0.

These properties showcase o1 tool steel’s robustness, making it suitable for applications where high strength, durability, and wear resistance are paramount.

Applications of o1 tool steel

The versatility and balanced properties of o1 tool steel make it suitable for an extensive range of applications across numerous industries. Its good combination of toughness, wear resistance, and ease of heat treatment makes it an excellent choice for general tooling.

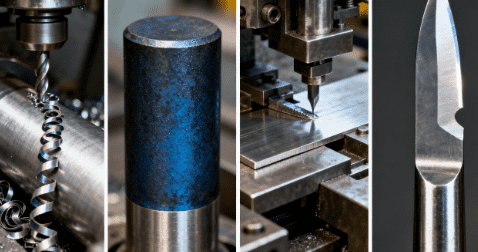

Common applications of o1 tool steel include:

- Cutting Tools: o1 tool steel is frequently chosen for industrial cutting tools such as blades, knives, and cutters, where maintaining sharpness is critical. It is also used for shear blades in metalworking, paper, and plastics industries, requiring high strength and edge retention. Specialized applications include surgical instruments like scalpels and scissors, food slicing blades, and custom knives for hobbyists.

- Molds and Dies: In the manufacturing sector, o1 tool steel is utilized for plastic injection molds, benefiting from its ability to hold fine details and resist wear. It can also be found in die casting dies for non-ferrous metals and alloys, offering wear resistance under high-pressure conditions. Other specific die applications include blanking dies, forming dies, laminating dies, trimming dies, thread dies, expanding dies, and drawing dies.

- Tooling for Cold Working: This is a primary area for o1 tool steel, used for making forming dies and tools in operations such as drawing, bending, and stamping, where its wear resistance and toughness are essential to withstand repetitive metal forming stresses. It is a common choice for manufacturing punches and piercing tools.

- Woodworking Tools: For tools like planer blades, router bits, and saw blades, o1 tool steel is valued for its ability to maintain sharpness and resist wear when cutting tough woods. Chisels and other precision hand tools also benefit from its excellent edge retention.

- Aerospace and Automotive Components: In these demanding industries, o1 tool steel is employed for high-precision components requiring hardness and dimensional stability, such as tooling for gears and shafts exposed to high stress. It is also used in stamping, bending, and forming dies for parts in the automotive sector.

- Measuring and Guiding Tools: Gauges, jigs, guides, and locating fixtures are often made from o1 tool steel due to its dimensional stability and hardness.

- Miscellaneous Tools and Parts: This includes machine parts, marking tools, shims, levers, and saws. Even for hot working tools, o1 tool steel can be employed in applications with moderately high temperatures, such as components in forging tools and hot stamping.

The broad range of applications for o1 tool steel underscores its reputation as a versatile and reliable material in tool making.

How to Anneal o1 tool steel

Annealing is a critical heat treatment process for o1 tool steel, primarily performed to soften the steel, relieve internal stresses, and improve its machinability before subsequent hardening operations. This process makes the material easier to work with, allowing for machining without the risk of excessive tool wear or distortion.

For o1 tool steel, the annealing process involves a precise heating and controlled cooling cycle:

1. Heating

The steel should be uniformly heated in a protected environment to an austenitizing temperature of approximately 1435°F (780°C). Protecting the steel is important to prevent decarburization, which is the loss of carbon from the surface, potentially affecting its final hardness.

2. Soaking

Once the target temperature is reached, the o1 tool steel should be held at this temperature for a sufficient period to ensure thorough heating throughout the material.

3. Controlled Cooling

After soaking, the steel is then slowly cooled within the furnace at a controlled rate of approximately 27°F (15°C) per hour, until it reaches a temperature of 1200°F (650°C). This slow cooling rate is crucial for allowing the steel’s microstructure to transform into a soft, ductile state.

4. Final Cooling

Once the temperature drops to 1200°F (650°C), the o1 tool steel can then be removed from the furnace and allowed to cool in ambient air to room temperature.

Proper annealing ensures that the o1 tool steel is in its most workable condition, preparing it for the next stages of manufacturing and precision shaping.

How to Heat Treat o1 tool steel

Heat treatment is the transformative process that unlocks the full potential of o1 tool steel, endowing it with its characteristic hardness, toughness, and wear resistance. This process involves specific steps: austenitizing, quenching, and tempering. The ease of heat treatment is one of the key advantages of o1 tool steel.

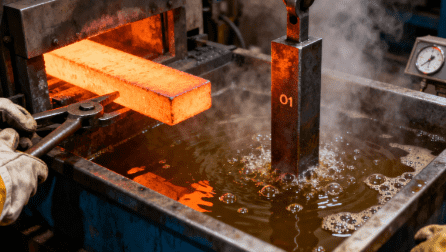

Quenching o1 tool steel

Quenching is the rapid cooling step following austenitizing, designed to “freeze” the high-temperature austenitic microstructure into a much harder martensitic structure. For o1 tool steel, this is an oil-hardening process.

The quenching procedure for o1 tool steel is as follows:

1. Austenitizing

First, the o1 tool steel needs to be uniformly heated to its austenitizing temperature. This temperature range is typically around 800-850°C (1472-1562°F). It is important to heat the steel in a protected atmosphere to prevent surface decarburization, which can lead to a softer surface layer.

2. Soaking

The steel is held at the austenitizing temperature for a sufficient period to ensure that the entire workpiece is uniformly heated and the carbon is fully dissolved into the austenite phase.

3. Oil Quenching

Immediately after soaking, the o1 tool steel is quenched in warm oil. The recommended temperature for the oil bath is usually between 125-150°F (49-66°C). The cooling rate during quenching should be uniform and sufficiently fast to avoid parts deforming, but also consider preventing excessive distortion and/or quench cracks. The oil quenching process is less aggressive than water quenching, which helps to minimize distortion and cracking in the steel.

Tempering o1 tool steel

Tempering is a crucial secondary heat treatment performed immediately after quenching. Its purpose is to reduce the brittleness of the freshly quenched martensite, relieve internal stresses, and fine-tune the hardness of the o1 tool steel to the desired level, while enhancing its toughness.

The tempering process for o1 tool steel typically follows these guidelines

1. Immediate Tempering

Tempering should commence as soon as the o1 tool steel has cooled to approximately 125-150°F (49-66°C) in the quenching oil. Delaying tempering can increase the risk of cracking due to residual stresses.

2. Temperature Selection

The tempering temperature is chosen based on the desired final hardness and toughness for the specific application. For o1 tool steel, to achieve a hardness typically between 55-62 HRC, tempering temperatures generally range from 150-200°C (302-392°F). It is advised not to let the tempering temperature fall below 360°F (182°C).

3. Soaking Time

The o1 tool steel should be held at the chosen tempering temperature for at least two hours. Longer soaking times may be necessary for larger or more complex sections to ensure uniform tempering throughout the material.

4. Double Tempering

To optimize properties and further relieve stresses, o1 tool steel is typically tempered twice. After the first tempering cycle, the material should be cooled to room temperature before commencing the second tempering cycle. This practice allows for a more complete transformation of any retained austenite and provides a more stable and tougher microstructure.

Proper heat treatment, encompassing precise austenitizing, careful oil quenching, and meticulous double tempering, is essential for achieving the optimal combination of hardness (55-62 HRC), toughness, and wear resistance that makes o1 tool steel such a highly valued material.

How to Harden o1 tool steel

Hardening o1 tool steel is a multi-step heat treatment process that involves heating the steel to a specific temperature, rapidly cooling it, and then reheating it to relieve stresses and achieve the desired final hardness and toughness. This entire process, including austenitizing, quenching, and tempering, is designed to transform the steel’s microstructure to impart superior mechanical properties. The ease of hardening is a significant advantage of o1 tool steel, making it a versatile choice.

The general steps for hardening o1 tool steel are as follows

1. Pre-Hardening Preparation (Annealing and Stress Relieving)

- Annealing: As discussed, if the o1 tool steel is received in a hardened or semi-hardened state, or if extensive machining is planned, annealing is performed first. This involves heating the steel to 1435°F (780°C), followed by a slow furnace cool to 1200°F (650°C), and then air cooling. This ensures the steel is soft and machinable.

- Stress Relieving: After rough machining, it is often beneficial to stress relieve the o1 tool steel. This involves heating the workpiece to 1200°F (650°C) and holding it for two hours. Subsequently, it is slowly cooled to 930°F (500°C), after which it can freely cool in air. This step helps prevent distortion during the critical hardening phase.

2. Austenitizing for Hardening

- The o1 tool steel is heated uniformly to an austenitizing temperature in the range of 800-850°C (1472-1562°F).

- It is crucial to maintain a protected atmosphere (e.g., vacuum furnace, inert gas, or pack hardening) during this heating phase to minimize decarburization, which is the loss of carbon from the surface of the steel. Decarburization can significantly reduce the surface hardness of the finished tool.

- The steel is held at this temperature for a sufficient time to allow the carbon to dissolve thoroughly into the austenite, ensuring a homogeneous microstructure for quenching. The soaking time depends on the thickness of the part, typically around 30-45 minutes for smaller sections, and longer for larger pieces.

3. Quenching

- Immediately after the austenitizing soak, the o1 tool steel is rapidly cooled by quenching it in warm oil. The oil temperature should be maintained between 125-150°F (49-66°C).

- The purpose of quenching is to transform the austenite into martensite, a very hard and brittle microstructure. Oil quenching is preferred for o1 tool steel because it provides a cooling rate that is fast enough to achieve high hardness but slower than water quenching, which helps to minimize thermal shock, distortion, and the risk of cracking.

- It is critical to ensure uniform cooling during quenching to avoid uneven hardness or warping.

4. Tempering

- Tempering is the final and essential step in the hardening process, and it must be performed immediately after quenching. Quenched o1 tool steel is extremely hard and brittle due to the martensitic structure and high internal stresses.

- The o1 tool steel is reheated to a lower temperature, typically between 150-200°C (302-392°F), to achieve the desired hardness range of 55-62 HRC. The specific tempering temperature will determine the final hardness; lower temperatures yield higher hardness but lower toughness, and vice versa.

- The part should be held at the tempering temperature for at least two hours.

- Double Tempering: It is highly recommended to perform a double temper. After the first tempering cycle, the steel is cooled to room temperature before being reheated for a second tempering cycle at the same temperature. Double tempering helps to transform any retained austenite that may have not transformed during the first cycle and further relieve stresses, leading to improved toughness and dimensional stability. Do not allow the tempering temperature to drop below 360°F (182°C).

By carefully following these steps for hardening, o1 tool steel can achieve its optimal balance of high hardness, wear resistance, and toughness, making it suitable for demanding tooling applications.

Other Treatments and Considerations for o1 tool steel

Beyond the core heat treatment processes, there are several other treatments and characteristics of o1 tool steel that are important for its performance and longevity.

Stress Relieving o1 tool steel

Stress relieving is a heat treatment process distinct from annealing, primarily aimed at reducing residual stresses that can build up in o1 tool steel during machining, cold working, or uneven cooling. These residual stresses, if not alleviated, can lead to distortion or cracking during subsequent heat treatment or in service.

For o1 tool steel, stress relieving is recommended after rough machining operations:

- Heating: The workpiece should be heated uniformly to a temperature of 1200°F (650°C).

- Soaking: Hold the material at this temperature for at least two hours to allow for adequate stress relaxation throughout the section.

- Cooling: After soaking, the o1 tool steel should be slowly cooled in the furnace to 930°F (500°C). Below this temperature, it can then be freely cooled in air to room temperature. This controlled cooling prevents the reintroduction of significant thermal stresses.

Surface Treatments for o1 tool steel

To further enhance the performance and extend the life of o1 tool steel tools, various surface treatments can be applied:

- Nitriding: This process introduces nitrogen to the surface of o1 tool steel, forming a hard top layer. This hard layer significantly improves wear resistance and can also enhance fatigue life.

- Carburizing: By introducing carbon to the surface of o1 tool steel, a hard carbide layer is built, which increases surface hardness and wear resistance.

- Carbonitriding: This process introduces both nitrogen and carbon into the surface layer, leading to improved surface hardness, wear resistance, and resistance to softening at elevated temperatures.

- Black Oxide Coating (Bluing): While providing some additional corrosion resistance, black oxide coating is primarily used to enhance the aesthetic appearance of o1 tool steel parts, giving them a black-blue surface coloration and reducing light reflection.

- PVD and CVD Coatings: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are processes that apply thin, hard coatings to the surface of o1 tool steel. These wear-resistant layers provide increased hardness and protection against abrasive wear.

Machining and Fabrication of o1 tool steel

o1 tool steel is known for its excellent machinability, which contributes to its popularity.

- EDM (Electrical Discharge Machining): o1 tool steel can be successfully machined using EDM in both its annealed and hardened states. However, EDM can introduce a heat-affected zone (HAZ) which may alter properties compared to the rest of the material. To restore uniformity, relieve stresses, or refine the microstructure, a tempering process can be performed after EDM.

- Forging: Forging o1 tool steel can refine its grain structure, which in turn improves mechanical properties such as toughness and fatigue strength. Additionally, forging helps to make the material more homogeneous and uniform, enhancing overall performance.

- Welding: Welding of o1 tool steel is possible, provided that appropriate welding precautions are taken to avoid issues like cracking or loss of hardness in the heat-affected zone.

- Cold Working: Like other steels, cold working o1 tool steel will lead to work hardening. This means the material may deform, become harder, and experience a reduction in ductility, which can increase the risk of cracking.

Corrosion Resistance of o1 tool steel

It is important to note that o1 tool steel has relatively low corrosion resistance. This is primarily due to its lack of high chromium content; for a steel to be considered truly corrosion resistant (like stainless steel), it generally requires at least 10.5% chromium. With a chromium content typically ranging from 0.4-0.7%, o1 tool steel is prone to rusting when exposed to moisture or harsh environments. To protect against corrosion, o1 tool steel may require surface treatments or coatings, or it should be kept dry and properly maintained.

Conclusion

o1 tool steel stands as a highly valued material in the realm of tool making and manufacturing, offering a robust balance of desirable properties. Its key strengths include high hardness, excellent edge retention, and commendable toughness. The material’s good machinability and the relative ease of its heat treatment process, which enables it to achieve a working hardness of 55-62 HRC through oil quenching and tempering, make it a versatile and cost-effective choice for a wide array of applications. This excellent combination of properties contributes to good tool life and production economy.

However, like all materials, o1 tool steel is not without its limitations. It possesses low corrosion resistance, making it susceptible to rusting if exposed to moisture or harsh environments without proper protection. It is also sensitive to decarburization during heat treatment if not properly protected.

Despite these minor drawbacks, by understanding its characteristics, applying correct processing techniques, and taking precautions against its weaknesses, o1 tool steel remains an outstanding choice for many tool and die manufacturers, as well as hobbyists. Its widespread use in cutting tools, molds, cold working tooling, and precision components across industries like automotive, aerospace, and medical, attests to its reliability and performance. For applications demanding precision, durability, and a sharp, long-lasting edge, o1 tool steel continues to be a go-to material, capable of unlocking impressive performance with just “1 Perfect Quench.”

FAQ

Q: What is o1 tool steel primarily used for?

A: o1 tool steel is widely used for producing a variety of tools that require high wear resistance, toughness, and sharpness. This includes cutting tools like blades, knives, and shear blades, as well as dies, molds, punches, woodworking tools, and precision components in industries such as automotive, aerospace, and medical equipment manufacturing. It is particularly popular for cold working applications.

Q: What hardness can o1 tool steel achieve after heat treatment?

A: After proper heat treatment, including oil quenching and tempering, o1 tool steel can achieve a hardness typically ranging between 55-62 HRC. This range makes it suitable for applications requiring sustained sharpness and wear resistance under moderate to high stresses.

Q: Is o1 tool steel corrosion resistant?

A: No, o1 tool steel has low corrosion resistance because it lacks the high levels of chromium (at least 10.5%) needed for stainless properties. It is prone to rusting when exposed to moisture or harsh environments, and therefore may require surface treatments or coatings for protection, or diligent maintenance to keep it dry.

Q: Is o1 tool steel magnetic?

A: Yes, as an iron-based metal, o1 tool steel is ferromagnetic and can be magnetized, making it suitable for magnetic clamping applications. However, its magnetic properties can be influenced by heat treatment.

Q: What are the main advantages of using o1 tool steel?

A: o1 tool steel offers several advantages, including a good balance of hardness, wear resistance, and ease of machining. It is relatively simple to heat treat and can hold a sharp edge well. It also provides good tool life and production economy, making it a cost-effective solution for a wide range of applications.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀