Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Military grade steel is a critical material category used across modern defense systems, from armor plates to missile components and high-performance military engines. Its strength, heat resistance, and durability make it a foundational material for weapons, protective systems, and aerospace structures.

This guide provides a full overview of the most important steel grades used throughout the military and defense sectors, supported by simple concepts, comparisons, and an FAQ to match real user search queries.

Military Grade Steel Basics: Key Concepts and Definitions

What Is Military Grade Steel?

Military grade steel refers to steel alloys specifically engineered for the demands of military use, including high hardness, extreme wear resistance, and stability under heat or impact.

These steels undergo specialized heat treatment and composition adjustment to meet stringent defense standards.

Why Military Grade Steel Is Different

Unlike conventional industrial steels, military grade steel is purpose-designed to resist ballistic impact, high-velocity friction, extreme heat, and structural fatigue.

Its microstructure is tightly controlled to ensure predictable mechanical behavior in mission-critical environments.

Core Material Properties

- Hardness — Resistance to abrasion and penetration.

- Toughness — Ability to absorb impact without fracturing.

- Red Hardness — Stability under high temperatures, especially important for weapons and engine parts.

- Fatigue Resistance — Withstanding repeated stress cycles, essential for aerospace and mechanical systems.

Applications of Military Grade Steel Across the Defense Industry

Armor and Protective Components (Key for Military Grade Steel Applications)

D2 Steel for Armor Plates

D2 steel is known for excellent wear resistance and high hardness, making it suitable for protective shielding and certain armor components. Its chromium content improves durability and enhances long-term performance.

D3 Steel for High-Wear Armor Inserts

D3 offers extremely high wear resistance, making it effective for armor elements that experience constant impact or abrasive conditions.

Its stability under repeated stress allows precise and reliable performance.

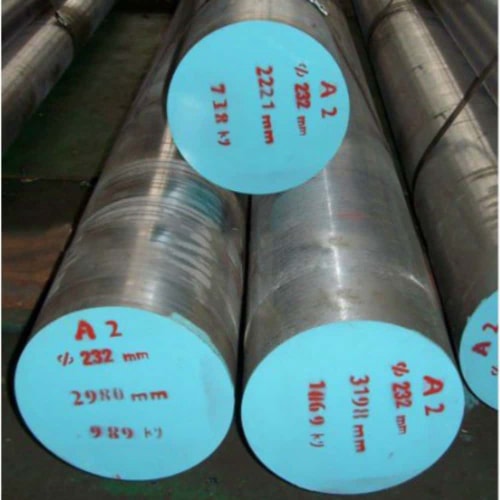

A2 Steel for Shock-Resistant Armor Parts

A2 steel balances hardness with toughness, making it ideal for components that require impact resistance equal to structural stability.

Its uniform hardness distribution provides consistent protection.

D6 Steel for Heavy-Duty Armor Systems

D6 is valued in scenarios where maximum hardness and wear resistance are critical.

It is commonly used in heavy armor applications requiring long-term structural integrity.

Weapon Manufacturing Steels (High-Performance Military Grade Steel Types)

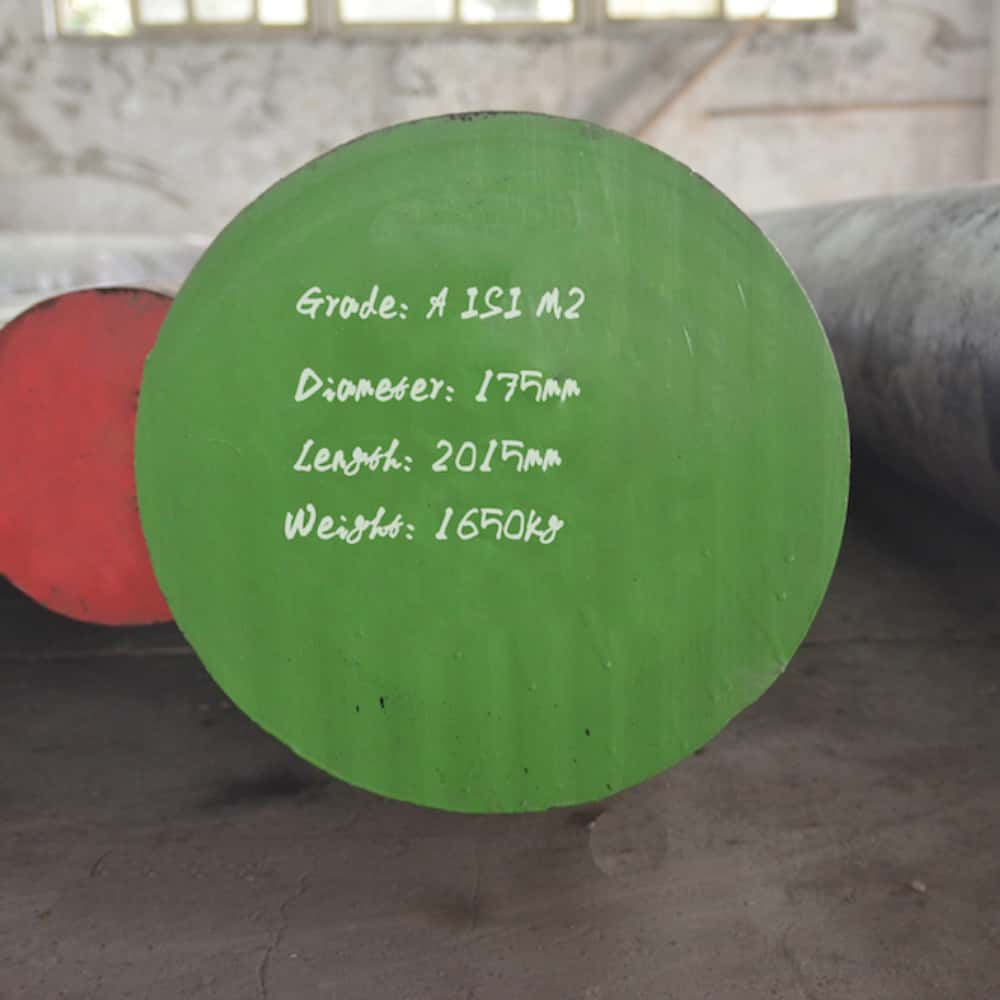

M2 Steel for Guns, Knives, and High-Speed Components

M2 high-speed steel offers excellent red hardness and wear resistance.

This makes it a preferred choice for gun barrels, weapon blades, and fast-moving mechanical weapon parts.

M3 Steel for Balanced Strength Components

M3 steel provides a well-balanced ratio of hardness to toughness, allowing it to be used in firearm mechanisms and precision weapon parts.

Its reliable performance makes it a versatile material across different weapons platforms.

M4 Steel for Extreme Wear Resistance

M4 steel demonstrates superior wear resistance under high pressure and friction, suitable for tactical blades, enhanced cutting components, and other defense-grade tools.

M7 Steel for Impact-Intensive Weaponry

M7 steel is formulated to withstand high-impact operations, making it valuable for components that undergo sudden loads or shocks during operation.

M35 and M42 Cobalt-Enriched Steels

These steels incorporate cobalt to enhance heat resistance and hardness retention.

They are used in specialized weapon parts that must endure sustained high temperatures and mechanical stress.

Missile and Aerospace Components (High-Temperature Military Grade Steel)

H11 Steel for Missile Control and Heat Zones

H11 provides strong resistance against heat and impact, ideal for control surfaces, nozzles, and moving parts exposed to extreme thermal conditions.

H13 Steel for Aerospace and High-Heat Missile Components

H13 is widely used for aerospace molds and missile subsystems due to its exceptional toughness, thermal fatigue resistance, and stability.

It performs reliably across changing temperature gradients, essential in rocketry and propulsion.

Military Engine Components (High-Speed, High-Temperature Steels)

Why High-Speed Steels Dominate Engine Systems

Military engines operate at higher loads and temperatures than civilian machinery, requiring steels that maintain hardness and structural integrity even under intense friction.

M-Series Steels in Engines (M2, M3, M4, M7, M35, M42)

These steels offer:

- Long-term wear resistance

- Superior heat stability

- Resistance to deformation at high RPM

Their combination of red hardness and strength under pressure makes them essential for gears, bearings, rotors, and turbine-adjacent systems.

Military Machinery Components (Structural and Mechanical Steel Types)

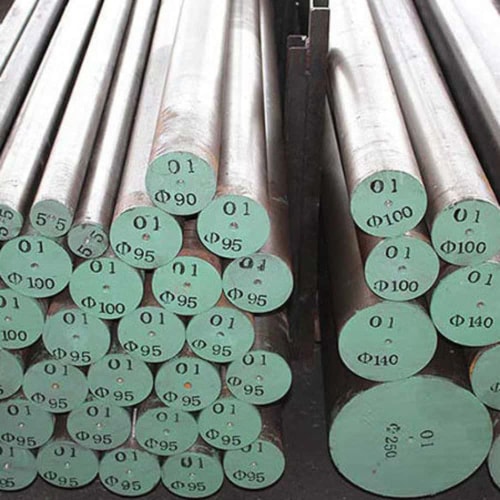

O1 Steel for Precision Mechanical Components

O1 steel’s dimensional stability and ease of heat treatment make it suitable for military mechanical parts requiring precise tolerances.

O2 Steel for Cold-Work Mechanical Systems

O2 steel provides higher toughness and is used in military frames, fixtures, and wear-heavy components requiring both strength and resilience.

D-Series Steels (D2, D3) in Machinery

These steels serve in cutting tools, dies, and other mechanical parts that must remain intact under long-term abrasive conditions.

Key Concepts in Military Grade Steel (Mini Concept Sections)

Heat Treatment in Military Steels

Heat treatment modifies the internal structure of steel to adjust hardness, toughness, and durability.

Military components require highly controlled processes to ensure consistent battlefield performance.

Wear Resistance vs. Toughness

Wear resistance refers to a steel’s ability to withstand abrasion, while toughness measures its ability to absorb energy without cracking.

Most military systems require a precise balance of both depending on their intended use.

Red Hardness Explained

Red hardness describes a material’s ability to stay hard at elevated temperatures—critical for weapons, engines, and aerospace components.

This property determines whether a steel can maintain structural performance during prolonged heating.

Fatigue Resistance in Military Materials

Fatigue resistance prevents micro-cracks from forming under repeated stress.

This is especially important in missiles, aircraft, or engines where vibration and cyclical loads are constant.

Comparisons to Help Choose the Right Military Grade Steel

D-Series vs. M-Series Steel

D-Series

- Optimized for hardness and wear resistance

- Ideal for armor and cutting components

M-Series

- High red hardness

- Designed for heat-intensive weapon and engine systems

Choice Guide:

Select D-series for impact or abrasion environments; choose M-series for heat-intensive mechanical systems.

H-Series vs. Other Aerospace Materials

H-Series

- Heat-shock resistant

- Strong under thermal cycling

Titanium Alloys

- Lighter weight

- High corrosion resistance but lower wear resistance

Choice Guide:

Use H-series for high-heat structural parts; use titanium for lightweight aerospace frames.

Military Grade Steel vs. Standard Industrial Steel

Military grade steels deliver extreme hardness, heat resistance, and fatigue resistance that standard carbon or alloy steels cannot match.

Industrial steels are cheaper and adequate for civilian applications but do not provide battlefield-level durability.

Conclusion

Military grade steel plays a fundamental role in defense technology, from armor systems to aerospace and weapon manufacturing. Understanding the differences between D-series, M-series, H-series, and O-series steels helps engineers and procurement teams select materials with the right balance of toughness, hardness, and heat performance.

With the concepts and comparisons provided in this guide, selecting the right steel for your military application becomes significantly easier and more informed.

FAQ

What exactly does “military grade steel” mean?

It refers to steels engineered to meet specific military standards, offering superior hardness, strength, and thermal stability compared to standard industrial steel.

Is military grade steel bulletproof?

Not all of it is. Some military grade steels are used for armor, but many are designed for weapons, engines, or aerospace components rather than ballistic protection.

Why do weapons often use M-series steel like M2 or M4?

M-series steels maintain hardness at high temperatures, making them ideal for friction-heavy components such as gun barrels or cutting edges.

What steel is commonly used in missile parts?

H11 and H13 steels are widely used because they can withstand extreme heat and rapid temperature changes during missile operation.

How do I choose the right steel for military applications?

Match the steel to the environment—D-series for wear, M-series for heat, O-series for precision tooling, and H-series for high-temperature aerospace or missile components.

Is military grade steel stronger than titanium?

It can be stronger in terms of wear resistance and hardness, but titanium is lighter and more corrosion-resistant. The “better” choice depends on the application.