Introduction

In the realm of manufacturing, materials play a pivotal role in determining the efficiency, durability, and quality of the end products. Hot work tool steel stands out as a crucial material in various manufacturing processes due to its exceptional properties. This blog delves into the significance of hot work tool steel in enhancing manufacturing processes, exploring its characteristics, applications, and advantages.

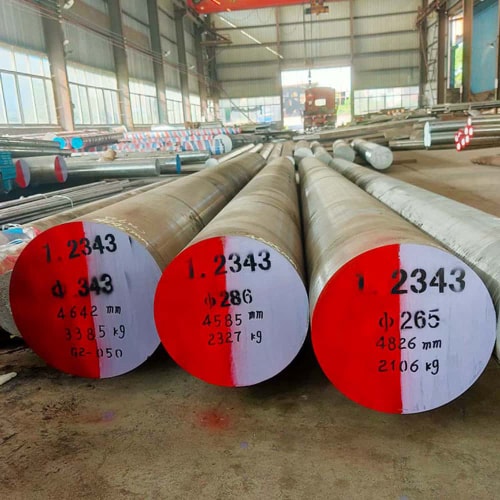

Understanding Hot Work Tool Steel

Hot work tool steel is a specialized alloy engineered to withstand high temperatures and mechanical stresses encountered in hot forming, forging, extrusion, and other similar processes. Its composition typically includes elements such as chromium, tungsten, molybdenum, and vanadium, imparting superior heat resistance, wear resistance, and toughness.

Applications in Manufacturing

Hot work tool steel finds widespread applications across various manufacturing sectors:

- Die Casting: Hot work tool steel dies endure extreme temperatures and pressures during the casting of molten metals, ensuring precise shaping and high-quality castings.

- Forging: Dies and tooling made from hot work tool steel withstand the intense heat and pressure involved in forging processes, maintaining dimensional accuracy and surface finish.

- Extrusion: The durability and thermal stability of hot work tool steel enable it to withstand the rigors of extrusion processes, ensuring consistent product dimensions and surface quality.

- Hot Stamping: Hot work tool steel components facilitate hot stamping processes by providing the necessary hardness, wear resistance, and thermal conductivity required for shaping metallic materials.

Advantages of Hot Work Tool Steel

Utilizing hot work tool steel offers several advantages for manufacturing processes:

- Extended Tool Life: Its superior heat resistance and wear resistance prolong tool life, reducing downtime and tool replacement costs.

- Enhanced Product Quality: Hot work tool steel maintains dimensional accuracy and surface finish, ensuring high-quality end products.

- Increased Productivity: Reduced tool wear and maintenance requirements lead to improved process efficiency and higher throughput.

- Versatility: Hot work tool steel’s versatility allows for the fabrication of complex shapes and intricate designs, expanding manufacturing possibilities.

Properties of Hot Work Tool Steel

| Property | Description |

|---|---|

| High Temperature Strength | Maintains mechanical properties at elevated temperatures |

| Wear Resistance | Resistant to abrasion and deformation |

| Toughness | Ability to absorb energy without fracturing |

| Machinability | Ease of shaping and machining |

Conclusion

Hot work tool steel stands as a cornerstone in modern manufacturing, empowering industries to achieve higher efficiency, precision, and quality in their processes. Its exceptional properties make it indispensable for a wide range of applications, from die casting to hot stamping. By harnessing the advantages of hot work tool steel, manufacturers can optimize their operations and stay competitive in today’s dynamic market landscape.

FAQ

Q: What distinguishes hot work tool steel from other steel alloys?

A: Hot work tool steel is specifically designed to withstand high temperatures and mechanical stresses encountered in hot forming processes, making it ideal for applications involving extreme heat and pressure.

Q: Can hot work tool steel be recycled?

A: Yes, hot work tool steel is recyclable. Scrap steel can be melted down and reused in the production of new steel alloys, contributing to sustainability efforts in manufacturing.

Q: How does hot work tool steel compare to cold work tool steel?

A: While both types of tool steel are designed for specific temperature ranges and applications, hot work tool steel exhibits higher temperature resistance and toughness compared to cold work tool steel, which is optimized for ambient temperature operations.

Q: Is hot work tool steel suitable for high-volume production environments?

A: Yes, hot work tool steel’s durability, heat resistance, and wear resistance make it well-suited for high-volume production environments where tool longevity and performance are critical factors.

Q: Can hot work tool steel be coated for additional protection?

A: Yes, hot work tool steel can be coated with various surface treatments or coatings to enhance wear resistance, reduce friction, and improve corrosion resistance, depending on the specific application requirements.