Tool Steel’s Influence on Innovation in Consumer Goods

Introduction

From appliances to personal electronics to recreational equipment, tool steel has become a hidden hero enabling innovation and performance improvements across many consumer products. Thanks to its specialized properties optimized for durability, tool steel allows product designers to push boundaries and pack more capability into modern consumer goods. This article explores the expanding applications of tool steel in consumer products, its influence on innovation opportunities, considerations in material selection, and recommendations to leverage tool steel most effectively.

Why Tool Steel for Consumer Goods?

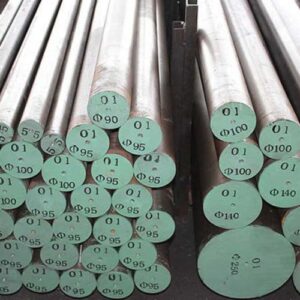

Tool steel refers to a versatile family of ultra-hardenable steels engineered specifically for use in tools and components needing exceptional wear resistance, strength, and reliability. Key characteristics make tool steel well-suited for consumer products:

Tool steel refers to a versatile family of ultra-hardenable steels engineered specifically for use in tools and components needing exceptional wear resistance, strength, and reliability. Key characteristics make tool steel well-suited for consumer products:

Hardness and Wear Resistance

Tool steel maintains sharp cutting edges, prevents surface abrasion damage, and resists indentation and deformation from repeated use, protecting product function and appearance.

Corrosion Resistance

Sufficient corrosion resistance prevents surface discoloration, pitting, and cracking that could undermine aesthetics and longevity in household products.

Strength and Fatigue Resistance

The combination of high strength and fatigue strength ensures tool steel consumer product components withstand repeated stresses and impacts without cracking or breaking.

Dimensional Stability

Minimal warping or distortion during manufacturing and use enables precise product fits, movements, and clearances needed for quality and durability.

Design Flexibility

The versatility to cast, machine, stamp, forge, and fabricate tool steel supports innovating consumer product geometries and consolidating components.

With these attributes, tool steel empowers longer-lasting, higher-performing, and more innovative consumer goods designs.

Expanding Tool Steel Applications in Consumer Products

Tool steel has become indispensable in the following consumer product applications:

Cutting Tools and Knives

Kitchen knives, scissors, razor blades, blenders, food processors, lawnmower blades, and garden shears all depend on tool steel to maintain ultra-sharp edges through prolonged use.

Security and Lock Hardware

The cylinders, tumblers, pins, keys, and strike plates in high-security door locks and safes utilize tool steel for precision, hardness, and corrosion resistance.

Recreational Equipment

The gears, bearings, surfaces, and mechanical components exposed to wear in sporting goods like golf clubs, bicycles, firearms, weights, and fitness machines employ tool steel for durability.

Household Appliances

Washing machines, blenders, vacuum cleaner parts, microwave components, and refrigerator mechanisms all benefit from tool steel’s strength, hardness, and corrosion resistance in high-wear areas.

Medical and Personal Care Products

Many electric grooming, massage, skin treatment, oral care, and other personal care devices incorporate tool steel into trimmer blades, massager tips, sonic cleaning transducers, and other components.

Ongoing innovation across consumer segments will continue driving expanded adoption of tool steel to enable more robust, precise products.

Tool Steel Grades for Consumer Goods

With its wide range of available grades, tool steel allows selecting properties optimized for different consumer product needs:

Cutting, Shaving, and Trimming

Maximize edge hardness and sharpness with high carbon tool steel grades such as A2, D2, M2. Add cobalt for increased toughness and edge stability.

Corrosion Resistance and Cleanability

Choose tool steel grades containing sufficient chromium like 420, 416, and 440C balanced for hardness, corrosion protection, and cost.

Decorative Finishes

For polished gold, nickel, or chrome plating select readily polished tool steel grades like 416, 430, and 303 without surface defects.

Strength and Wear Resistance

Grades like A2, D2, and S7 provide an optimized combination of hardness, tensile strength, and fatigue resistance on friction surfaces like gears, bearings, and pivots.

Thermal Processing Suitability

For tool steel components requiring hardening or other heat treatment after fabrication choose grades like P20, H13, or 420 with known processing behaviors.

Matching each tool steel grade’s nuanced property capabilities to individual consumer product demands ensures ideal long-term functionality.

Tool Steel Manufacturing Advantages

In addition to outstanding in-service properties, tool steel offers manufacturing advantages that enable innovation:

Castability

Melting and casting tool steel allows consolidating complex consumer product components into durable one-piece castings reducing assemblies and fasteners.

Machinability

The ability to precision machine, grind, turn, and drill tool steel facilitates component geometries with much tighter tolerances and better surface finish than castings or plastic parts.

Stamping and Forming

Tool steel’s formability when hot supports high-volume stamped, pressed, or forged consumer product parts with thinner walls and more intricate shapes than achievable with other metals.

Joining Flexibility

Tool steel allows joining options including welding, brazing, adhesive bonding, swaging, and sintering. This supports flexibility in consumer goods assembly techniques.

Finishing Options

Tool steel’s polishability facilitates decorative mechanical finishing or luxurious plated finishes. Smooth surface perfection showcases quality.

Capitalizing on these manufacturing advantages provides paths to reduce costs while innovating better consumer products.

Case Studies of Tool Steel in Consumer Goods

Here are some examples of tool steel enabling innovation across consumer categories:

Forged Golf Club Heads

Moving from cast stainless to forged 1025 tool steel allowed enlarging club head hollow volumes for weight distribution innovations and forged surface textures for improved impact friction and control.

Die Cast Blender Jar Coupling

Switching to a H13 tool steel coupling increased coupling hardness to 500HB for improved wear resistance, allowing torque capacity boosts enabling faster blender speeds.

Metal Injection Molded Knife Blades

Metal injection molding of 420 stainless tool steel provided more complex blade edge geometries with cheracteristics unattainable by stamping or machining. This improved edge retention.

Additive Manufactured Razor Handles

3D printing handles from maraging tool steel enabled more ergonomic designs combining flexibility and stiffness transition zones in one-piece constructions eliminating assembly.

Micro-Textured Kitchen Knife Surfaces

Applying deterministic micro-texturing onto tool steel knife surfaces reduced drag, enabled easier food release, and improved lubricity for quicker, lower-effort slicing while retaining corrosion resistance.

These examples demonstrate tool steel’s versatility enabling diverse consumer product improvements through advanced processing and manufacturing.

Future Innovations in Tool Steel for Consumers

Several emerging capabilities provide additional pathways to leverage tool steel in next generation consumer goods:

Several emerging capabilities provide additional pathways to leverage tool steel in next generation consumer goods:

Metal Matrix Composites

Reinforcing tool steel with micron-sized carbide particles or nanotubes yields composites boasting superior wear resistance and mechanical properties for longer-lasting edges and surfaces.

Advanced Surface Engineering

Applying advanced low-friction, release, antimicrobial, or decorative coatings only where needed enhances tool steel’s functionality and aesthetics in targeted regions of consumer products.

Improved Modelling

Physics-based simulations of tool steel performance can accelerate product designs and optimization of tool steel grade, coating, texture, and geometry configurations.

Hybrid Manufacturing

Combining additive manufacturing with advanced surface engineering allows bespoke tool steel consumer products with complex personalized geometries, textures, and properties tailored to individual needs.

Embedded Sensors

Microsensors embedded in tool steel product components could provide feedback on temperature, strains, corrosion, and micro-defects enabling smart products that self-diagnose issues and improve user safety.

Automated Recycling

Expanded capabilities to effectively sort, recycle, and reprocess tool steel scrap enables a circular supply chain for consumer goods supporting sustainability.

Harnessing these types of emerging innovations will uncover novel ways tool steel can enhance consumer product experiences, performance, and differentiation.

Key Recommendations for Leveraging Tool Steel

To gain maximum advantage from tool steel across consumer product lines, key recommendations include:

- Select optimized tool steel grades based on service stresses, hardness needs, temperature, geometries, joining needs, and cost.

- Utilize modelling and prototyping with tool steels early in design to assess manufacturability and lifetimes.

- Apply specialized tool steel surface enhancements like coatings and texturing only where needed locally to maximize bulk component life.

- Consolidate components where possible via one-piece castings or additive manufacturing with tool steel to improve durability.

- Embed unique material signatures and sensors in tool steel components to verify authenticity and enable smart products.

- Implement digital tracking of tool steel inventory and usage data to optimize production plans and sustainment.

- Collaborate across the supply chain to maximize recycled and remanufactured tool steel content.

Making tool steel selection and optimization a priority provides avenues to enhance consumer product differentiation, reliability, and sustainability.

Conclusion

In summary, tool steel is an enabling material positioned to expand its indispensable role across diverse consumer products thanks to its tailored properties, flexible processing options, and ongoing advanced material innovations. Strategic adoption of optimized tool steel grades and manufacturing processes allows designers to pack more performance, personalization, durability, and capabilities into next-generation consumer goods across outdoor equipment, appliances, electronics, dental care, personal grooming, household items, and recreational segments. With tool steel’s help, the possibilities for consumer product innovation and improvement appear limitless.

Frequently Asked Questions on Tool Steel in Consumer Goods

How does tool steel benefit consumer product performance?

Tool steel provides crucial properties like hardness, wear and corrosion resistance, high strength, fatigue resistance, dimensional precision, and aesthetics that enable enhanced durability, reliability, quality, and capabilities in consumer goods.

What consumer products use tool steel currently?

Tool steel sees major use in knives, blades, locks, medical devices, sporting goods, fitness equipment, appliances, personal care products, jewelry, and recreational equipment where hardness, strength, or corrosion resistance are vital.

What tool steel grades work best for consumer goods?

Grades are selected based on needs for hardness (A2, D2), corrosion resistance (416, 420, 440C), finishability (303, 416), toughness (S7, 1045), manufacturability (H13, P20), and cost (12L14, 1117).

How does tool steel support manufacturing innovative consumer designs?

Castability, machinability, formability, surface finish potential, joining flexibility, consolidation options, and emerging processes like additive manufacturing provide innovative benefits with tool steel.

What future capabilities could enhance tool steel consumer uses?

Additive manufacturing, metal matrix composites, advanced coatings, hybrid manufacturing, embedded sensors, modelling, automation, and improved recycling offer new pathways for leveraging tool steel in future consumer goods.

How can the value of tool steel be maximized in consumer products?

Upfront collaborative design optimization, localized treatments only where needed, consolidated manufactured parts, inventory tracking for recycling, and supply chain collaboration on grades and data management maximize tool steel benefits.

How will tool steel support consumer product innovation going forward?

Tool steel’s expanding capabilities will enable consumer product breakthroughs in personalized production, smart connected products, custom alloys and geometries, and sustainable circular supply chains.