Introduction

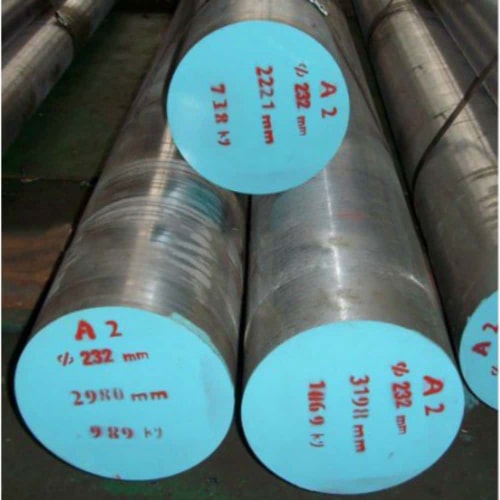

A2 tool steel stands out in the realm of manufacturing materials due to its exceptional properties, making it a preferred choice for various industrial applications. This blog delves into the innovative uses of tool steel A2 in modern manufacturing processes, exploring its key characteristics, advantages, and real-world applications.

Key Characteristics of A2 Tool Steel

A2 tool steel is renowned for its impressive combination of hardness, wear resistance, and machinability. These properties make it highly suitable for demanding applications where durability and precision are paramount.

| Characteristic | Description |

|---|---|

| Hardness | A2 tool steel is typically hardened to a Rockwell hardness of 60-62, ensuring it retains its edge and resists deformation under stress. |

| Wear Resistance | It exhibits excellent resistance to wear and abrasion, making it ideal for tools subjected to high impact and repetitive use. |

| Machinability | A2 tool steel is known for its ease of machining and grinding, allowing for intricate shapes and precise finishes to be achieved efficiently. |

| Toughness | It offers good toughness, even in larger sections, reducing the risk of cracking or fracturing during use. |

| Dimensional Stability | High dimensional stability during heat treatment ensures consistency in tooling and component production. |

Applications in Tooling and Dies

One of the primary applications of A2 tool steel is in tooling and die manufacturing, where its robust properties are put to optimal use:

- Punches and Dies: Tool steel A2 is widely employed in the fabrication of punches and dies used in stamping and forming operations. Its hardness and wear resistance ensure prolonged tool life and maintain dimensional accuracy.

- Cutting Tools: The material is also utilized for cutting tools such as shear blades and thread rolling dies. Its excellent machinability allows for the creation of sharp cutting edges that endure high-stress environments.

- Injection Molding: In injection molding processes, tool steel A2 is preferred for manufacturing mold cavities and cores due to its ability to withstand repeated thermal cycling and maintain surface finish integrity.

Advanced Heat Treatment Techniques

To further enhance its properties, A2 tool steel undergoes advanced heat treatment methods:

- Quenching and Tempering: This process enhances both hardness and toughness, striking a balance that is critical for tool longevity and performance under varying operational conditions.

- Cryogenic Treatment: Additional cryogenic treatment improves wear resistance and dimensional stability, reducing internal stresses and enhancing overall tool life.

Case Studies: Real-World Applications

A2 tool steel finds widespread use across several key industries, each benefiting from its unique set of attributes:

- Automotive Industry: Tool steel A2 is integral in the production of forging dies and cutting tools used to manufacture automotive components. Its high wear resistance and toughness ensure consistent performance and extended tool life, contributing to efficient production processes.

- Aerospace Applications: In aerospace manufacturing, tool steel A2 is essential for forming dies used in shaping sheet metal parts and for cutting tools required to machine high-strength alloys. Its exceptional machinability and dimensional stability are crucial for producing intricate components with precision and reliability.

Comparison of A2 Tool Steel with Other Tool Steels

| Property | A2 Tool Steel | D2 Tool Steel | O1 Tool Steel |

|---|---|---|---|

| Hardness (HRC) | 60-62 | 58-62 | 60-62 |

| Wear Resistance | Excellent | Very Good | Good |

| Toughness | Good | Fair to Good | Very Good |

| Machinability | Easy | Difficult | Moderate |

| Dimensional Stability | High | Moderate | Moderate |

Conclusion

In conclusion, A2 tool steel remains a cornerstone material in modern manufacturing, prized for its unmatched combination of hardness, wear resistance, and machinability. Its versatility spans across industries such as automotive, aerospace, and tool and die making, where precision and durability are non-negotiable. As technological advancements continue to push boundaries, A2 tool steel is poised to play an increasingly pivotal role in shaping the future of industrial production.

FAQ

Q: What are the main advantages of using A2 tool steel?

A: A2 tool steel offers high hardness, excellent wear resistance, and good machinability, making it ideal for tooling and die applications where durability and precision are crucial.

Q: How does tool steel A2 compare with other tool steels like D2 and O1?

A: Compared to D2 and O1, tool steel A2 generally offers similar hardness levels but with better machinability and dimensional stability. It also provides good toughness, making it suitable for applications requiring resistance to chipping and deformation.

Q: What industries commonly use A2 tool steel?

A: A2 tool steel is widely used in industries such as automotive, aerospace, and tool and die making, where its properties contribute to the production of high-performance components and tools.