Introduction

In the realm of industrial applications, the choice of materials can significantly impact performance, durability, and overall efficiency. Among the myriad of options, M2 tool steel stands out as a premier choice for various tools and components. Renowned for its exceptional hardness, wear resistance, and heat resistance, M2 tool steel has earned its place as a staple in industries ranging from manufacturing to aerospace. This blog aims to delve into the characteristics and advantages of M2 steel, shedding light on why it is favored by engineers and manufacturers worldwide.

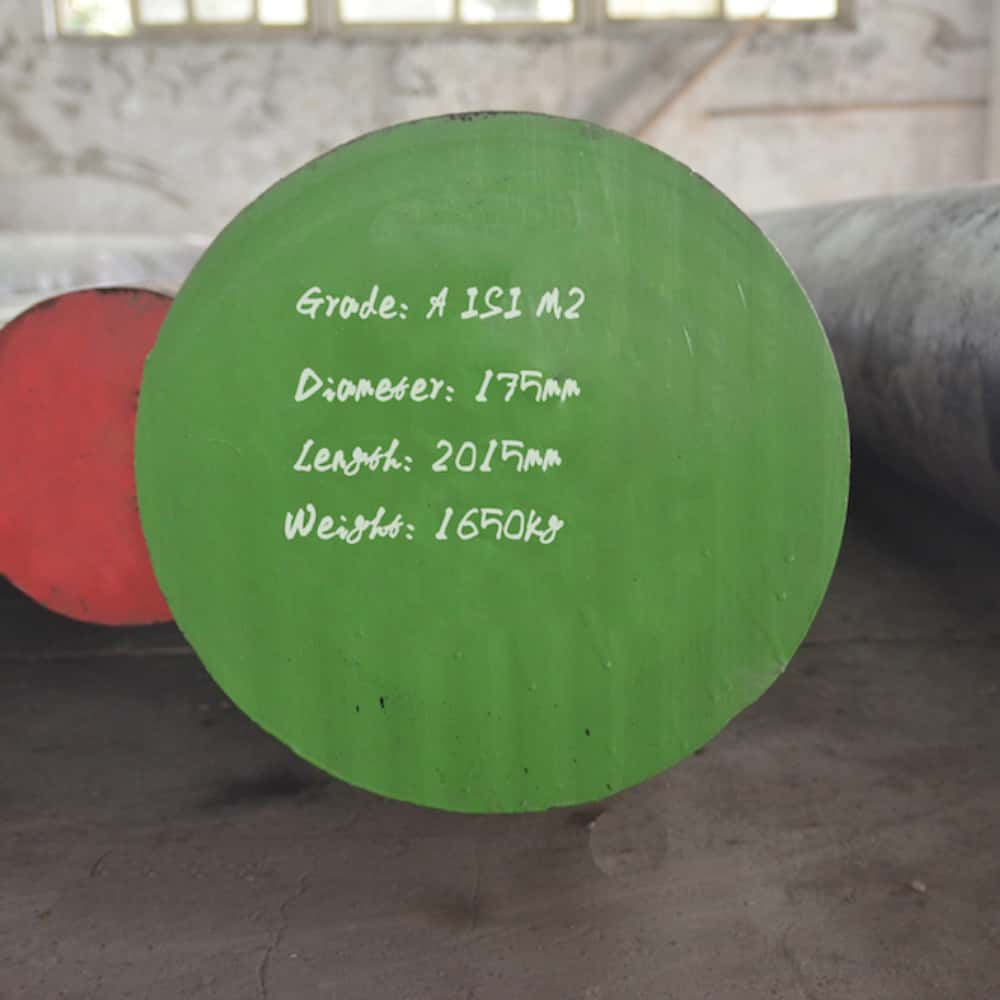

Understanding M2 Tool Steel

M2 tool steel, also known as high-speed steel (HSS), is a type of tungsten-molybdenum high-speed steel renowned for its exceptional properties. Its composition typically includes high levels of carbon, tungsten, molybdenum, chromium, vanadium, and sometimes cobalt, imparting unique attributes ideal for demanding industrial environments.

High Hardness: M2 steel exhibits remarkable hardness, allowing it to withstand high levels of stress and wear. With a hardness range of 60-65 HRC, it outperforms many other tool steel variants in hardness tests.

Superior Wear Resistance: The combination of carbides and alloying elements in M2 steel results in outstanding wear resistance, making it suitable for cutting, machining, and forming applications where prolonged tool life is essential.

Excellent Heat Resistance: M2 steel retains its hardness and mechanical properties even at elevated temperatures, thanks to its high heat resistance. This property ensures consistent performance in high-speed machining operations without compromising tool integrity.

Good Toughness: Despite its exceptional hardness, M2 steel maintains adequate toughness, reducing the risk of fracture or chipping during use. This balance between hardness and toughness enhances tool longevity and reliability.

Versatility: M2 steel finds applications across various industries, including aerospace, automotive, manufacturing, and metalworking. Its versatility stems from its ability to maintain performance across a wide range of operating conditions and applications.

Advantages of M2 Tool Steel

- Extended Tool Life: M2 steel’s exceptional hardness and wear resistance translate to prolonged tool life, reducing downtime and maintenance costs.

- Enhanced Productivity: By withstanding high-speed machining operations and maintaining cutting-edge sharpness, M2 steel enhances productivity in manufacturing processes.

- Consistent Performance: Its excellent heat resistance ensures consistent performance even under demanding conditions, resulting in high-quality and precision-engineered components.

- Cost Efficiency: While M2 steel may have a higher initial cost compared to other materials, its longevity and performance justify the investment by minimizing replacement and maintenance expenses.

Applications of M2 Tool Steel

The superior properties of M2 tool steel make it invaluable in a myriad of industrial applications:

| Industry | Application |

|---|---|

| Aerospace | Cutting tools |

| Automotive | Drill bits |

| Manufacturing | End mills |

| Metalworking | Reamers |

| Tool and Die Making | Punches and dies |

Conclusion

In conclusion, the superiority of M2 tool steel in industrial applications is evident through its exceptional hardness, wear resistance, and heat resistance. Its versatility, coupled with extended tool life and enhanced productivity, makes it a preferred choice for engineers and manufacturers worldwide. By understanding the unique properties and advantages of M2 steel, industries can optimize performance and achieve unparalleled efficiency in their operations.

Through meticulous research and analysis, this blog has provided insights into why M2 tool steel remains at the forefront of materials selection in various industrial sectors. Its unmatched combination of properties continues to drive innovation and excellence, shaping the future of manufacturing and engineering.

By harnessing the potential of M2 steel, industries can elevate their capabilities, meet the demands of modern manufacturing, and strive towards greater efficiency and competitiveness.

FAQ

Q: Is M2 tool steel suitable for high-temperature applications?

A: Yes, M2 tool steel exhibits excellent heat resistance, making it suitable for high-temperature machining operations.

Q: How does M2 tool steel compare to other tool steel variants?

A: Compared to conventional tool steels, M2 tool steel offers superior hardness, wear resistance, and heat resistance, making it a preferred choice for demanding applications.

Q: Can M2 tool steel be easily machined?

A: While M2 tool steel is relatively hard, it can be machined using appropriate cutting tools and techniques designed for high-speed steels.