Introduction

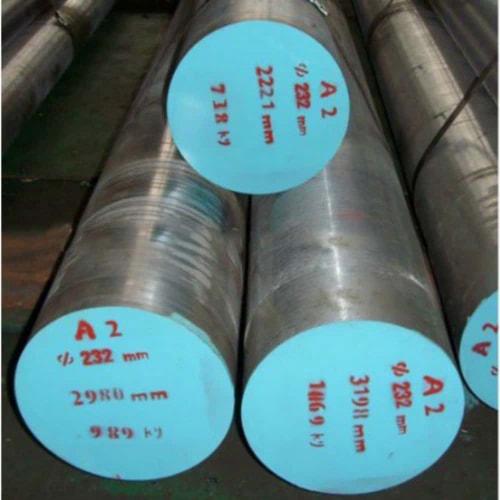

In this comprehensive guide, we delve into the properties, applications, machining considerations, and advantages of A2 tool steel round bars. A2 tool steel is renowned for its excellent combination of toughness, wear resistance, and machinability, making it a preferred choice in various industrial applications.

What is A2 Tool Steel?

A2 tool steel is an air-hardening, cold-work steel known for its high toughness and dimensional stability during heat treatment. It contains chromium, molybdenum, and vanadium which contribute to its exceptional wear resistance and strength.

Properties of A2 Tool Steel Round Bar

A table summarizing the key properties of A2 tool steel, including hardness, toughness, and chemical composition, is provided below:

| Property | Value |

|---|---|

| Hardness | HRC 60-62 |

| Toughness | High |

| Wear Resistance | Excellent |

| Composition | 1.00% C, 5.25% Cr, 0.95% Mn |

| Heat Treatment | Annealing, Hardening, Tempering |

Applications of A2 Tool Steel

A2 tool steel round bars find applications in:

- Tooling: A2 tool steel round bars are widely employed in tooling applications such as punches, dies, and gauges due to their exceptional toughness and wear resistance. These components endure high stress and repeated impact, where A2’s ability to resist deformation ensures prolonged tool life and reliability in demanding manufacturing environments.

- Cutting Tools: In cutting tool applications, including shear blades and thread rolling dies, A2 tool steel’s combination of high hardness and toughness is crucial. This steel maintains sharp edges and withstands abrasion, ensuring efficient cutting performance and extended tool longevity. Machinists appreciate A2’s capability to retain dimensional stability during intense cutting operations, enhancing precision and consistency in manufacturing processes.

- Molds: A2 tool steel round bars are favored for molding applications, including plastic molds and die casting dies, where dimensional accuracy and durability are paramount. The steel’s superior wear resistance and machinability contribute to the production of high-quality molds that maintain intricate shapes over prolonged use. A2’s ability to resist deformation under varying temperatures and pressures ensures reliable performance in molding complex components for diverse industrial applications.

Machining A2 Tool Steel Round Bar

Machining A2 tool steel requires:

- Tools: Carbide inserts, high-speed steel tools.

- Techniques: Slow speeds, ample coolant to prevent overheating.

- Considerations: Annealing before machining improves machinability.

Advantages of A2 Tool Steel Round Bar

The benefits of using A2 tool steel include:

- Durability: A2 tool steel’s robust composition enables it to withstand deformation under high stress conditions, making it ideal for applications where tools are subjected to intense pressure and impact. This durability ensures consistent performance and extended tool life, reducing downtime and maintenance costs in manufacturing operations.

- Versatility: The versatility of A2 tool steel extends across various tooling applications, from punches and dies to cutting tools and molds. Its balanced combination of toughness and wear resistance allows manufacturers to use A2 steel in diverse industrial sectors, adapting to specific requirements without compromising on performance or reliability.

- Ease of Machining: During machining operations, A2 tool steel maintains dimensional stability, which is critical for achieving precise and accurate components. This stability reduces the risk of dimensional changes or distortions, ensuring consistency in part production and minimizing scrap. Machinists appreciate A2’s ease of machining, which simplifies the manufacturing process and enhances overall productivity.

Maintenance and Care

Proper maintenance involves:

- Storage: Dry environment to prevent corrosion.

- Cleaning: Regular cleaning to remove contaminants.

- Inspection: Periodic inspection for signs of wear or corrosion.

Conclusion

A2 tool steel round bars offer a robust solution for tooling and machining needs, combining toughness with excellent wear resistance. Understanding its properties and applications helps in optimizing performance across various industrial sectors.

FAQ

Q: What is the heat treatment process for A2 tool steel?

A: Heat treatment involves annealing, followed by hardening at a specific temperature range and tempering to achieve desired hardness and toughness.

Q: How does A2 tool steel compare to D2 steel?

A: A2 steel is known for better toughness and machinability compared to D2 steel, which has higher wear resistance.

Q: Can A2 tool steel round bars be welded?

A: Yes, A2 tool steel can be welded using conventional welding techniques, although precautions must be taken to avoid cracking.

Q: What industries commonly use A2 tool steel round bars?

A: Industries such as automotive, aerospace, and manufacturing utilize A2 tool steel for its durability and reliability in tooling applications.