Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

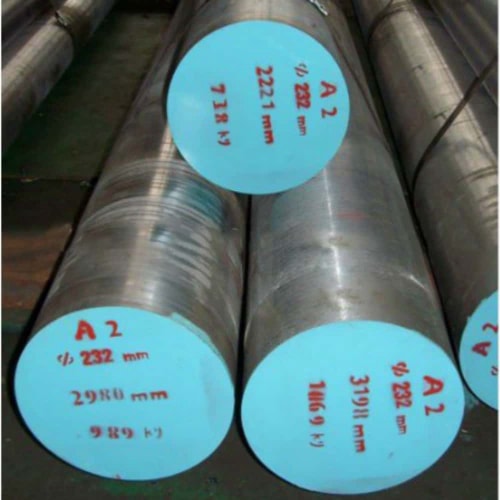

When it comes to selecting cold work tool steels for high-performance industrial or precision applications, the debate between D2 vs A2 tool steel has become a central topic among engineers, fabricators, and manufacturers. These two popular grades offer different balances of hardness, toughness, and wear resistance, making each one suitable for specific operational environments.

Choosing between D2 vs A2 tool steel is not just a matter of numbers on a datasheet. It directly affects the life cycle of your tooling, maintenance intervals, heat treatment results, and the quality of your end products. Whether you’re involved in die-making, knife production, cold stamping, or high-impact forming, knowing the right steel can lead to better results, lower costs, and superior durability.

This in-depth guide explores seven critical factors that differentiate D2 and A2. We’ll also provide an easy-to-read comparison table to help you evaluate which grade fits your specific project needs.

Chemical Composition and Microstructure: The Foundation of Steel Behavior

To understand how each grade performs, we must first examine the underlying chemistry that defines their core properties. The differences between D2 vs A2 tool steel begin with composition.

D2 Tool Steel (1.2379)

D2 steel is a high-carbon, high-chromium cold work steel known for its superior wear resistance and edge retention. The high chromium content (11–13%) provides semi-stainless characteristics, while vanadium and molybdenum increase hardness and durability.

A2 Tool Steel (1.2363)

A2 is an air-hardening tool steel that balances good wear resistance with excellent toughness. Its chromium content (~5%) is lower than D2, but its higher molybdenum level enhances its dimensional stability and impact resistance.

Mechanical Properties: Strength, Toughness, and Stability Compared

The mechanical differences between D2 vs A2 tool steel impact their usage in industrial tooling. D2 emphasizes wear resistance, while A2 favors toughness and impact resistance. Here’s how they stack up:

| Property | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Tensile Strength (MPa) | ≥2000 | 670–710 |

| Yield Strength (MPa) | ≥1800 | 345–350 |

| Elongation (%) | 11 | 41 |

| Reduction Area (%) | 12 | 21 |

| Charpy Impact (J) | 24 | 12 |

| Hardness (HRC after HT) | Up to 62 | Up to 60 |

| Dimensional Stability | Medium | Excellent |

| Distortion After HT | Low | Very Low |

From this table, it’s evident that D2 tool steel is significantly harder and more wear-resistant. However, A2 tool steel’s ductility and impact resistance make it ideal for applications with high shock loads.

Performance in Cutting and Forming Applications

In the world of cutting, forming, and shaping tools, the choice between d2 vs a2 tool steel directly impacts not only the cutting precision and forming success but also the long-term cost of tool maintenance and the frequency of replacement. The comparison of d2 vs a2 tool steel is essential for professionals working in environments that demand durability, precision, and consistent performance from their tooling materials.

D2 Tool Steel Use Cases

D2 is highly favored for industrial blades, cutting dies, shears, slitting tools, and metal stamping applications. In the context of d2 vs a2 tool steel, D2 stands out for its exceptional edge retention, which translates to fewer sharpening intervals and longer cutting sessions. However, the trade-off for this advantage is its brittleness—D2 is less forgiving under high-impact stress, and chipping can occur if the tool is mishandled or overloaded during operation.

A2 Tool Steel Use Cases

Within the comparison of d2 vs a2 tool steel, A2 demonstrates superior toughness and shock absorption. It excels in stamping dies, forming tools, and cold forming applications. Thanks to its inherent ability to resist cracking, A2 is often the preferred choice for tooling that must endure repeated impact or heavy forming cycles. Its resilience in variable work environments makes it a popular candidate in general-purpose fabrication.

Machinability, Heat Treatment, and Surface Finish

One of the most underrated aspects when comparing d2 vs a2 tool steel is how each material behaves during machining and heat treatment. The way these steels respond during preparation can significantly influence production costs and tool life.

Heat Treatment Characteristics

D2 tool steel air-hardens to extremely high hardness levels, a trait that is central to many d2 vs a2 tool steel discussions. However, it can be prone to distortion if the heat cycle is not carefully controlled. In many applications, D2 also benefits from cryogenic treatment to minimize retained austenite, thereby improving dimensional accuracy and stability in the final tool.

In contrast, A2 tool steel offers excellent dimensional stability during heat treatment, which is a key differentiator in the d2 vs a2 tool steel decision process. A2 is commonly chosen for molds and dies requiring tight tolerances and consistent shape retention after hardening.

Machinability and Finish

Machinability is another factor where the d2 vs a2 tool steel comparison reveals key differences. D2 presents challenges in machining due to its high hardness and the presence of chromium carbides, which wear down cutting tools quickly. However, once machined and polished, D2 provides a high-quality surface finish, making it suitable for precision cutting tools and dies.

A2, on the other hand, is easier to machine prior to hardening and still yields satisfactory surface finishes. In discussions of d2 vs a2 tool steel, machinists often favor A2 for its predictability and ease of toolpath programming, particularly when time and cost constraints are tight.

Real-World Application Suitability

Whether you’re working in aerospace, automotive, food processing, or woodworking, understanding the suitability of D2 vs A2 tool steel ensures long-term efficiency.

D2 Tool Steel Is Ideal For:

- Metal shearing and slitting tools

- Cold forming dies and blanking punches

- Food processing knives

- Industrial woodworking blades

- High-wear components in high-volume production

A2 Tool Steel Is Ideal For:

- Impact-loaded forming tools

- Die casting components

- Stamping dies for tough materials

- Cold forming punches

- General-purpose cutting and shaping tools

Durability and Maintenance in Long-Term Use

When considering long-term applications, the comparison of d2 vs a2 tool steel reveals notable trade-offs in durability and maintenance requirements. D2 tool steel is highly praised for its superior edge retention and outstanding wear resistance, making it a preferred option for tooling tasks involving repeated abrasion and precision cutting. Over time, the excellent hardness of D2 helps reduce the frequency of sharpening, thereby increasing operational uptime.

However, this same hardness makes D2 slightly more brittle, especially when exposed to sudden impact or uneven force distribution. In environments where tools are subjected to corrosive substances, D2 may require surface treatments or protective coatings to prevent premature wear or oxidation. These additional steps can extend tool longevity but may also introduce added maintenance considerations in certain working conditions.

A2 tool steel, on the other hand, offers a more balanced performance in terms of toughness and ease of upkeep. In the context of d2 vs a2 tool steel, A2 stands out for its better shock resistance and lower susceptibility to cracking. This makes it particularly useful in industries where tools are frequently exposed to variable stresses, slight misuse, or suboptimal working angles. Maintenance for A2 tends to be more straightforward, and its performance remains more stable over time in general-purpose applications.

For users seeking a steel grade that is easier to repair and maintain with minimal effort, A2 provides a practical solution, especially in environments where tool handling is less controlled or conditions vary significantly. When weighing d2 vs a2 tool steel in terms of long-term serviceability, the choice ultimately depends on whether the application favors extreme wear resistance or better structural resilience under fluctuating loads.

Cost and Availability

Price and accessibility are often decisive factors when choosing between d2 vs a2 tool steel. D2 steel generally commands a higher market price, mainly due to its higher chromium content and more intricate heat treatment processes. These characteristics not only enhance its wear resistance but also increase production costs, making D2 a more premium option among cold work steels.

On the other hand, A2 tool steel is widely regarded as a cost-effective alternative. It is easier to machine, less complex to heat treat, and has a lower alloying content compared to D2. These factors contribute to reduced manufacturing and tooling costs over the lifecycle of the product. In situations where budget constraints are a concern or where tooling turnover is relatively high, A2 may represent a more economical and efficient choice.

Still, when evaluating d2 vs a2 tool steel from a long-term investment perspective, D2 can often justify its initial expense by offering extended operational life. For industries that prioritize maximum wear resistance and infrequent replacement—such as metal stamping or injection molding—D2 may deliver superior value over time. The decision often hinges on the intended application, expected tool stress levels, and how frequently tools need to be maintained or replaced.

Ultimately, both options present viable advantages, but the selection of d2 vs a2 tool steel should be made with consideration for both immediate budget and future durability expectations.

Conclusion

The debate between D2 vs A2 tool steel is more than academic—it’s a real-world decision with practical implications. Here’s a quick breakdown:

- Choose D2 when wear resistance and edge retention are paramount, especially in high-stress cutting or forming tasks.

- Opt for A2 when toughness, dimensional stability, and impact resistance are more critical than maximum hardness.

Each steel has its own unique strengths, and selecting the right one ensures better performance, lower costs, and longer tool life in your production cycle.

FAQ

Is D2 steel harder than A2?

Yes. D2 tool steel is generally harder than A2 after heat treatment, with a maximum hardness of up to 62 HRC compared to A2’s 60 HRC.

Which is better for stamping—D2 or A2?

It depends on the material being stamped. D2 is better for clean, repetitive cuts with minimal shock. A2 is superior for high-impact or interrupted cutting due to its toughness.

Does A2 tool steel rust more easily than D2?

Yes. D2 has higher chromium content, offering semi-stainless properties. A2 has less chromium and thus lower corrosion resistance.

Is D2 harder to heat treat than A2?

Yes. D2 requires more controlled heat treatment and often benefits from cryogenic processing. A2 is easier to treat and offers better stability.

Which steel is more cost-effective?

A2 is generally more affordable upfront and easier to work with, making it a cost-effective choice for medium-duty applications. D2, while pricier, pays off in high-volume or wear-intensive environments.