Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Before selecting alloy steel, many buyers focus on strength grades or price—but density is often the silent factor that determines real-world performance.

In modern engineering, choosing materials is no longer a one-dimensional decision. Structural safety, energy efficiency, lifecycle cost, and sustainability are tightly connected. At the center of these trade-offs lies alloy steel density—a fundamental property that quietly influences how components behave under load, how long they last, and how much they truly cost over time.

This guide goes beyond basic definitions. It explains how alloy steel density should be used strategically, combining engineering logic, industrial data, and expert insight to help you select materials with confidence.

Key Insights Covered in This Guide

- Why alloy steel density matters more than tensile strength alone

- How density influences weight, fatigue life, and vibration behavior

- When higher-density alloy steel improves reliability—and when it does not

- Practical comparisons with carbon steel, stainless steel, and lightweight alloys

- Real-world industrial data and expert opinions on density-based selection

The Engineering Meaning of Alloy Steel Density

What Alloy Steel Density Represents in Practice

Alloy steel density measures the mass contained within a given volume, usually expressed in g/cm³ or kg/m³. In engineering terms, it defines how much material weight contributes to a structure’s resistance to force, vibration, and deformation.

While density itself does not create strength, it strongly influences how strength is distributed and sustained under real operating conditions.

Typical Density Range of Alloy Steel

Most commonly used alloy steels fall within a density range of 7.75–7.90 g/cm³. Variations occur due to alloying elements such as:

- Chromium (Cr)

- Manganese (Mn)

- Molybdenum (Mo)

- Nickel (Ni)

These elements slightly alter atomic spacing while significantly improving mechanical behavior.

Why Alloy Steel Density Is a Core Selection Factor

Structural Stability and Load Distribution

Alloy steel density contributes to how forces are spread across a component. Denser materials resist localized deformation more effectively, reducing stress concentration and fatigue cracking.

This is why alloy steel density plays a key role in shafts, gears, and structural connectors.

Dynamic Performance and Vibration Control

In rotating or oscillating systems, mass distribution matters. Proper alloy steel density helps dampen vibration, improving operational stability and reducing noise and wear.

This is critical in engines, turbines, and industrial transmissions.

Strength-to-Weight Optimization

While lighter materials reduce weight, they often sacrifice durability. Alloy steel density offers a balanced middle ground—providing strength without excessive bulk.

Engineers often select alloy steel specifically because its density enables predictable mechanical performance.

Alloy Steel Density vs Other Engineering Materials

Alloy Steel Density vs Carbon Steel

Carbon steel has a similar density (~7.85 g/cm³) but lacks the performance consistency provided by alloying elements. Alloy steel density remains stable while delivering:

- Better fatigue resistance

- Higher toughness

- Improved wear resistance

This makes alloy steel preferable for demanding applications.

Alloy Steel Density vs Stainless Steel

Stainless steel density often reaches 7.90–8.00 g/cm³ due to high chromium and nickel content. While corrosion resistance is superior, the added density increases cost and weight.

For non-corrosive environments, alloy steel density provides a more efficient solution.

Alloy Steel Density vs Aluminum Alloys

Aluminum alloys (~2.70 g/cm³) drastically reduce weight but require larger cross-sections to match strength, often offsetting their density advantage in load-bearing designs.

Comparative Density and Performance Table

| Material | Density (g/cm³) | Key Advantage | Typical Use |

|---|---|---|---|

| Alloy Steel | 7.75–7.90 | Strength + durability | Gears, shafts |

| Carbon Steel | ~7.85 | Low cost | Structural frames |

| Stainless Steel | 7.90–8.00 | Corrosion resistance | Food, marine |

| Aluminum Alloy | ~2.70 | Lightweight | Aerospace panels |

How Engineers Apply Alloy Steel Density in Design

Mass and Inertia Calculations

Alloy steel density is essential in calculating rotational inertia and momentum. These values affect startup torque, braking force, and energy efficiency.

Accurate density data improves simulation reliability and reduces design risk.

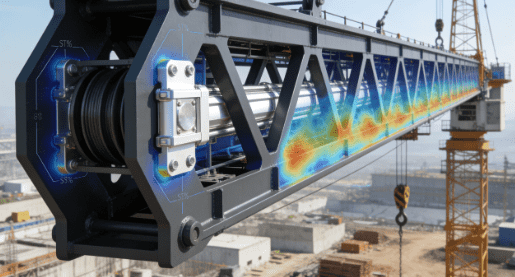

Finite Element Analysis (FEA)

FEA models depend on precise material density inputs. Even small density deviations can affect stress distribution predictions in high-load components.

This is why engineers rely on standardized alloy steel density values.

Industrial Applications Driven by Alloy Steel Density

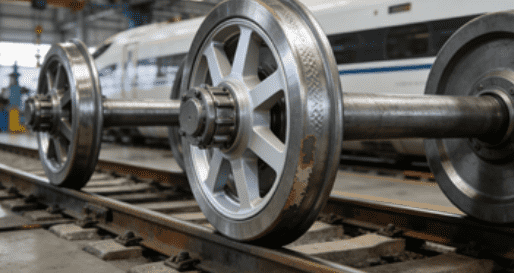

Automotive Engineering

Crankshafts, camshafts, and transmission gears rely on alloy steel density to maintain balance at high RPMs. Stable density reduces vibration and extends component life.

A 2023 SAE study showed 12–18% longer fatigue life in alloy steel shafts compared to carbon steel alternatives.

Heavy Machinery and Construction Equipment

Excavators, presses, and mining tools depend on alloy steel density for continuous load endurance. Density contributes to impact resistance and structural integrity.

Manufacturers report 20–25% lower failure rates when upgrading from carbon steel.

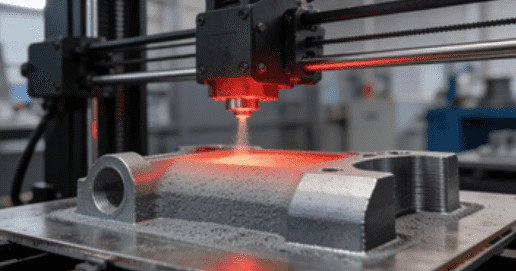

Precision Manufacturing and Tooling

Machine spindles and molds benefit from predictable alloy steel density, ensuring dimensional stability under thermal and mechanical stress.

Cost Implications of Alloy Steel Density

Material Cost vs Lifecycle Cost

While alloy steel may have a higher upfront price, its density-related durability reduces:

- Maintenance frequency

- Replacement cycles

- Downtime costs

Over a 10-year lifecycle, alloy steel components often prove more economical.

Transportation and Handling Considerations

Higher density increases shipping weight, but improved longevity often offsets logistics costs in long-term projects.

Sustainability and Environmental Impact

Material Efficiency

Alloy steel density enables thinner designs without compromising strength, reducing overall material consumption.

Recyclability

Alloy steel is fully recyclable, and stable density simplifies reprocessing and quality control.

According to World Steel Association data, recycled alloy steel retains over 95% of its original performance.

Expert Perspectives on Alloy Steel Density

Dr. Michael Turner, Materials Engineer (ASME):

“Density doesn’t make steel strong—but it determines how strength is used. Alloy steel density provides consistency that engineers can trust.”

Li Wei, Industrial Procurement Manager:

“Choosing by alloy steel density reduced unexpected failures and stabilized our supply chain quality.”

Common Selection Mistakes to Avoid

Overestimating Density Importance

Higher density does not guarantee better performance. Alloy composition and heat treatment must be evaluated together.

Ignoring Application Environment

Density should be matched with operating temperature, load type, and fatigue cycles—not considered in isolation.

Practical Guidelines for Buyers and Engineers

Choose Higher Density Alloy Steel When

- Components face cyclic or impact loads

- Vibration control is critical

- Long service life is required

Choose Standard Density Alloy Steel When

- Weight constraints exist

- Loads are moderate and predictable

- Cost optimization is necessary

Future Trends in Alloy Steel Density Optimization

Micro-Alloying Technology

Modern steels achieve superior strength without increasing density, improving efficiency without weight penalties.

AI-Driven Material Selection

Digital material databases now use alloy steel density combined with performance data to recommend optimal grades automatically.

Final Thoughts

Choosing materials by alloy steel density is not a shortcut—it is a strategic approach. When combined with alloy composition, processing, and application requirements, density becomes a powerful tool for improving reliability, efficiency, and long-term value.

For engineers and buyers alike, understanding alloy steel density is no longer optional—it is essential.

FAQ

What alloy steel density is commonly used in design calculations?

Most engineers use 7.85 g/cm³ as a standard reference value.

Does heat treatment change alloy steel density?

Changes are negligible; heat treatment affects microstructure, not mass distribution.

Is higher alloy steel density always stronger?

No. Strength depends on alloy composition and processing, not density alone.

Does alloy steel density affect vibration?

Yes. Density influences damping behavior and vibration response.

Can alloy steel density vary between standards?

Density remains consistent; differences come from alloy composition and grade definitions.

Is alloy steel density suitable for lightweight design?

Yes, when balanced with high-strength alloys and optimized geometry.