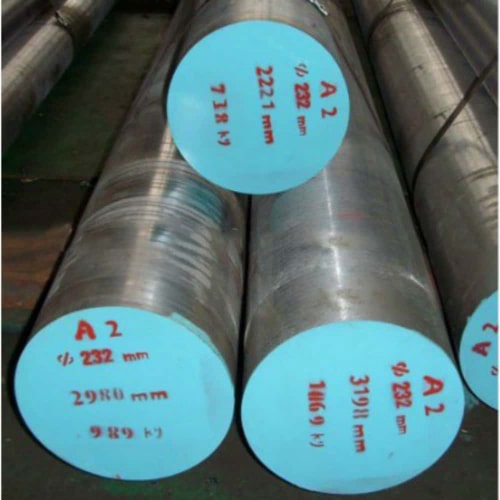

D2 vs A2 Tool Steel: Pros and Cons in 2025

Choosing between d2 vs a2 tool steel? Compare their pros and cons in our 2025 expert guide.

Choosing between d2 vs a2 tool steel? Compare their pros and cons in our 2025 expert guide.

Discover 4 surprising facts about A2 Tool Steel Yield Strength and why it’s a top choice for tough, high-precision tooling.

Avoid costly mistakes—learn to read the S7 tool steel Rockwell hardness chart like a pro.

Discover 8 expert insights into D2 Steel for Knives and learn why it’s trusted for edge retention, durability, and serious performance.

Unlock 8 expert hacks to supercharge O2 Tool Steel durability! Learn pro tips to extend lifespan & boost performance now.

Protect your molds! Discover 3 crucial tests for H13 Mold Steel quality. Avoid costly failures—click now for expert insights.

Discover why O1 Steel for Knives is the ultimate choice for durability, edge retention, and performance in cutting tools and blades.

Think you know Knife Tool Steel? Discover 6 shocking myths and what really matters in blade performance.

30+years steel industry experience, providing professional service with qualified steel products.

Qilu Steel is a leading supplier of high-quality tool steel with extensive experience in the industry. Our investment in a specialized factory further demonstrates our commitment to being at the forefront of the tool steel industry. We offer a wide range of tool steel grades, including P20, H13, D2, and S7, each with unique properties suited for different applications.

Quick Links

Website Group

Explore

Copyright © 2024 Qilu steel