M3 High Speed Steel vs T1 and M2: The Ultimate Comparison

Discover how M3 High Speed Steel outperforms T1 and M2 in wear resistance, heat retention, and machinability for high-performance tools.

Discover how M3 High Speed Steel outperforms T1 and M2 in wear resistance, heat retention, and machinability for high-performance tools.

Discover 5 proven M42 Steel machining tips to boost tool life, precision, and efficiency in industrial applications.

Unlock the secrets of O1 Tool Steel heat treatment! Achieve 55-62 HRC hardness with the perfect quench for superior performance.

Choosing between 8Cr13MoV vs D2 Steel? Discover key differences in hardness, toughness, and wear resistance now.

Discover the secret to long-lasting knives with these 5 high-performance knife steels designed for precision.”

Master tool steel essentials in 3 minutes and take your craftsmanship to the next level. Don’t miss out!

A2 vs D2 Tool Steel: Which is better for your project? Learn about the 5 critical application gaps and make the right choice today.

Discover why H11 vs H13 steel is crucial for your hot work molds. Learn the advantages of each to optimize mold performance and durability.

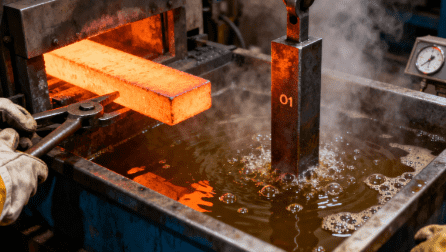

30+years steel industry experience, providing professional service with qualified steel products.

Qilu Steel is a leading supplier of high-quality tool steel with extensive experience in the industry. Our investment in a specialized factory further demonstrates our commitment to being at the forefront of the tool steel industry. We offer a wide range of tool steel grades, including P20, H13, D2, and S7, each with unique properties suited for different applications.

Quick Links

Website Group

Explore

Copyright © 2024 Qilu steel