S‑7 Tool Steel : Best Choice for Impact Tools

Discover why S‑7 Tool Steel is the ultimate choice for impact tools, combining toughness, durability, and superior performance.

Discover why S‑7 Tool Steel is the ultimate choice for impact tools, combining toughness, durability, and superior performance.

Discover how Steel Resists structural stress with science-based insights, real data, and expert analysis for stronger, safer designs.

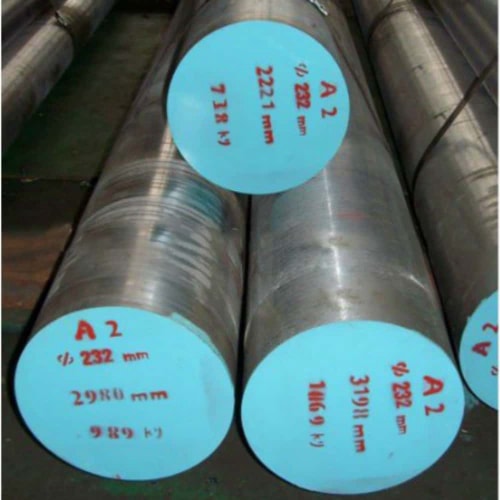

Discover the 6 essential properties of A2 Tool Steel that ensure durability, precision, and superior performance in industrial applications.

Explore SKD11 vs D2 vs Cr12MoV to find the ideal steel for stamping dies, industrial blades, and long-lasting tool performance.

This blog delves into the importance of H13 tool steel heat treatment in tool manufacturing, exploring its benefits, processes, and best practices.

Your 2025 expert guide to military grade steel—learn its uses in armor, missiles, engines, and modern weapon technology.

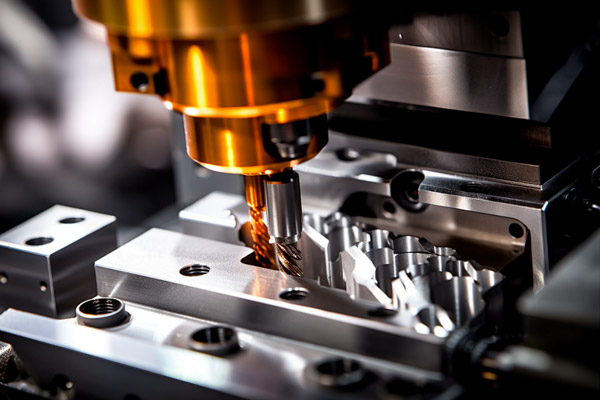

Compare popular Tool Steel Types and grades to make smarter choices for mold making, stamping, and high-speed cutting tools.

440C vs D2 Steel guide: Discover pros, cons, and practical applications to make the right material choice.

30+years steel industry experience, providing professional service with qualified steel products.

Qilu Steel is a leading supplier of high-quality tool steel with extensive experience in the industry. Our investment in a specialized factory further demonstrates our commitment to being at the forefront of the tool steel industry. We offer a wide range of tool steel grades, including P20, H13, D2, and S7, each with unique properties suited for different applications.

Quick Links

Website Group

Explore

Copyright © 2024 Qilu steel