H13 vs H10 Hot work tool steel Comparison: Which Hot Work Die Steel Performs Better?

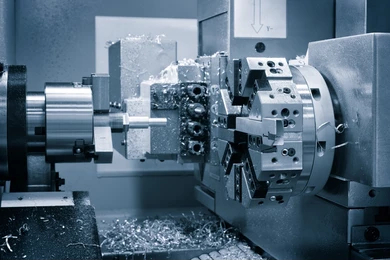

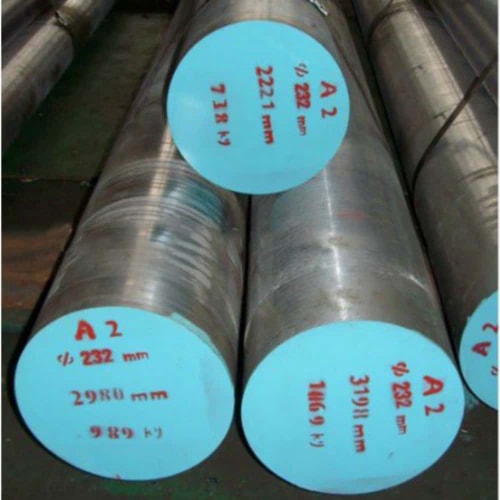

When evaluating H13 vs H10 Hot work tool steel, engineers are usually balancing toughness, thermal fatigue resistance, tempering stability, and long-term production cost. Both grades belong to the H-series hot…