5 Dangerous Myths About Tool Steel Debunked

Uncover 5 dangerous myths about Tool Steel and learn the facts that boost performance, cut costs, and extend tool life.

Hello, welcome to our tool steel knowledge sharing platform. We will regularly share various knowledge points in the field of tool steel. Our purpose is to spread this knowledge to help more technicians and companies engaged in the tool field understand industry trends and choose correct and high-quality tool materials.

Uncover 5 dangerous myths about Tool Steel and learn the facts that boost performance, cut costs, and extend tool life.

Discover the differences between 3Cr13 Steel vs D2 for precision manufacturing. Learn which steel is best for your application.

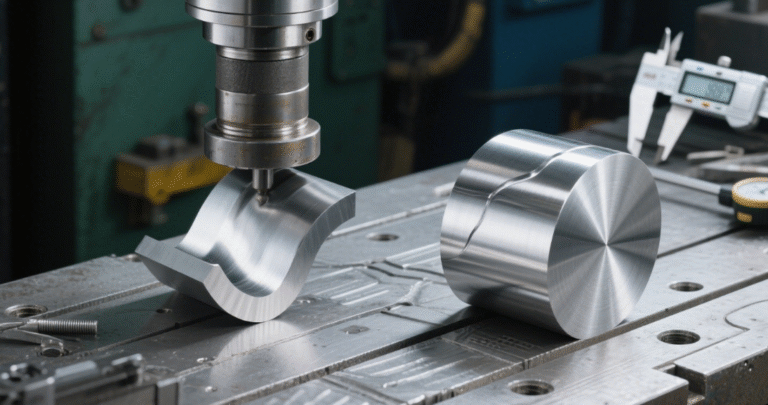

Achieve perfect tolerance control in your steel parts with reliable steel processing services. Precision and quality you can trust.

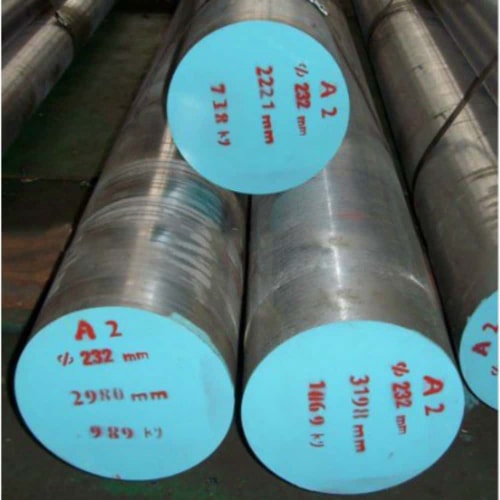

Looking for precision tools with enhanced durability? A2 Steel offers the best surface finish and high wear resistance.

Discover how O1 Steel performs in high-speed cutting. Learn its benefits, applications, and limitations for optimal performance!

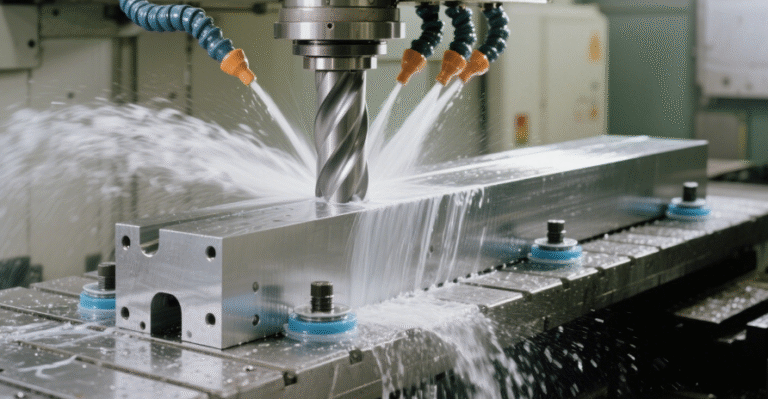

Discover how Turning enhances surface finish in metal parts, boosting durability, performance, and aesthetic appeal!

CNC Pros Choose Bar Stock Metal: 5 Key Facts on Efficiency, Waste Reduction & Durability. Read Now!

Everything to know about A2 Tool Steel: Composition table, heat treatment steps & FAQs. Perfect for manufacturers & hobbyists alike.

30+years steel industry experience, providing professional service with qualified steel products.

Qilu Steel is a leading supplier of high-quality tool steel with extensive experience in the industry. Our investment in a specialized factory further demonstrates our commitment to being at the forefront of the tool steel industry. We offer a wide range of tool steel grades, including P20, H13, D2, and S7, each with unique properties suited for different applications.

Quick Links

Website Group

Explore

Copyright © 2024 Qilu steel