D3 vs O1 Cold Work Tool Steel: Practical Selection Guide for Toolmakers

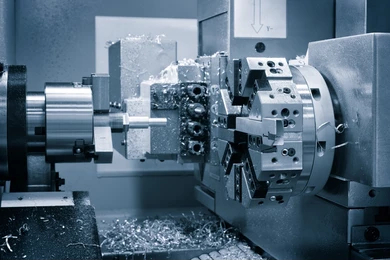

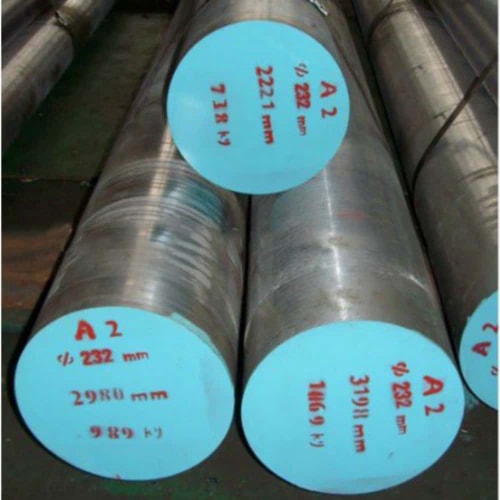

D3 vs O1 Cold Work Tool Steel is a frequent choice set for toolmakers specifying dies, punches and shear blades. This guide focuses tightly on direct comparisons—chemistry, microstructure, heat treatment…