Introduction

Hot rolled steel material is a versatile material that has been widely used in various industries for centuries. It is produced by heating steel billets to a high temperature and then rolling them into desired shapes. This process results in a material with unique properties that make it suitable for a wide range of applications. In this article, we will delve into the benefits of using hot rolled steel material and explore its various applications.

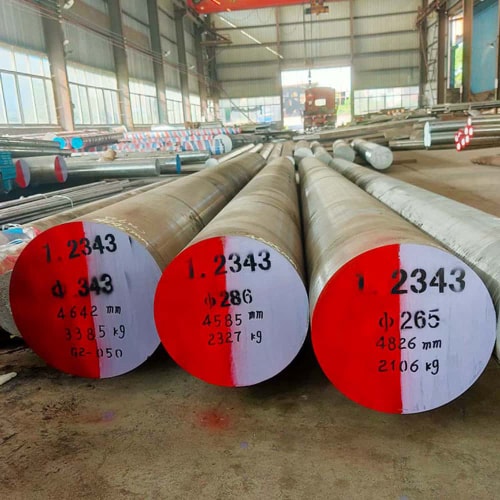

Understanding Hot Rolled Steel Material

Before we discuss the benefits, it is essential to understand what hot rolled steel is and how it differs from cold rolled steel. Hot rolled steel is produced at high temperatures, above the recrystallization temperature of the steel. This process alters the grain structure of the steel, resulting in a material with a more uniform and coarse grain structure. Cold rolled steel, on the other hand, is produced by rolling steel at room temperature, resulting in a finer grain structure and a smoother surface finish.

Advantages of Hot Rolled Steel Material

- Cost-Effective: Hot rolled steel material is generally more cost-effective than cold rolled steel due to the simpler manufacturing process. The high-temperature rolling process also allows for the production of larger quantities of steel in a shorter time.

- Superior Strength: Hot rolled steel possesses excellent strength and durability, making it ideal for applications that require high load-bearing capacity. The coarse grain structure contributes to its toughness and resistance to impact.

- Easy to Weld: The coarse grain structure of hot rolled steel makes it easier to weld compared to cold rolled steel. This property is particularly beneficial in fabrication processes where welding is a critical component.

- Versatility: Hot rolled steel can be easily formed and shaped into various profiles, such as beams, channels, and angles. This versatility makes it suitable for a wide range of applications in construction, manufacturing, and automotive industries.

- Dimensional Tolerance: While hot rolled steel may have slightly larger dimensional tolerances compared to cold rolled steel, it is often sufficient for many applications. The cost savings associated with the larger tolerances can be significant.

Applications of Hot Rolled Steel Material

Hot rolled steel material finds applications in a wide range of industries, including:

- Construction: Hot rolled steel material is used for structural components in buildings, bridges, and other infrastructure projects. Its strength and durability make it an ideal choice for these applications.

- Automotive: Hot rolled steel material is used in the manufacturing of automotive components, such as frames, chassis, and body panels. Its formability and weldability make it suitable for complex automotive designs.

- Manufacturing: Hot rolled steel is used in the manufacturing of various products, including machinery, equipment, and appliances. Its strength and versatility make it a valuable material for these applications.

- Agriculture: Hot rolled steel material is used in the construction of agricultural equipment, such as tractors, combines, and trailers. Its durability and resistance to corrosion make it suitable for outdoor use.

Comparison of Hot Rolled Steel Material and Cold Rolled Steel

| Feature | Hot Rolled Steel Material | Cold Rolled Steel |

|---|---|---|

| Manufacturing Process | High temperature rolling | Room temperature rolling |

| Grain Structure | Coarse | Fine |

| Surface Finish | Rougher | Smoother |

| Strength | High | High, but slightly lower than hot rolled |

| Ductility | Good | Good |

| Cost | Lower | Higher |

| Applications | Structural, automotive, manufacturing, agriculture | Precision parts, automotive body panels, appliances |

Conclusion

Hot rolled steel material is a versatile and cost-effective material with a wide range of applications. Its superior strength, durability, and weldability make it an ideal choice for many industries. While cold rolled steel may offer a smoother surface finish and tighter tolerances, hot rolled steel remains a popular choice due to its overall performance and cost-effectiveness.

FAQ

What is the difference between hot rolled steel material and cold rolled steel?

Hot rolled steel material is produced at high temperatures, resulting in a coarse grain structure and a rougher surface finish. Cold rolled steel is produced at room temperature, resulting in a finer grain structure and a smoother surface finish.

Is hot rolled steel stronger than cold rolled steel?

Generally, hot rolled steel is stronger than cold rolled steel due to its coarse grain structure. However, the strength difference can vary depending on the specific grade and application.

What are the common applications of hot rolled steel material?

Hot rolled steel material is commonly used in construction, automotive, manufacturing, and agriculture industries. It is used for structural components, automotive parts, machinery, equipment, and agricultural equipment.

Which type of steel is better for welding?

Hot rolled steel is generally easier to weld than cold rolled steel due to its coarse grain structure. This makes it a preferred choice for welding applications.