Table of Contents

Introduction to Automotive Alloy Steel

What is Automotive Alloy Steel?

Automotive alloy steel refers to specially engineered steels used in car manufacturing to achieve high strength, toughness, and wear resistance. These steels can be low-alloy, medium-alloy, or high-alloy grades and are designed to meet demanding automotive requirements.

Importance in Modern Automotive Industry

Automotive alloy steel is crucial for safety, durability, and performance. It is widely used in chassis components, engine parts, suspension systems, and structural elements, ensuring vehicles withstand stress, collisions, and long-term wear.

Market Overview

The automotive alloy steel market is expanding globally due to the rise of electric vehicles, lightweight design trends, and stricter safety and emissions regulations. In China, high-performance alloy steels are increasingly adopted for premium cars and heavy-duty applications.

Types of Automotive Alloy Steel

Classification by Performance and Application

High-Strength Alloy Steel

Used for chassis, suspension arms, and structural frames to provide high tensile strength and impact resistance.

Wear-Resistant Alloy Steel

Ideal for engine components, gears, and transmission parts that require surface durability and long lifespan.

Corrosion-Resistant Alloy Steel

Alloyed or coated steels used for body panels, exhaust systems, and fuel lines, protecting against rust and chemical exposure.

Classification by Material Type

Low Alloy Steel

Cost-effective and suitable for general automotive parts with moderate strength requirements.

Medium Alloy Steel

Balances strength, toughness, and wear resistance for critical components.

High Alloy Steel

Contains higher levels of alloying elements like chromium, nickel, or molybdenum for demanding engine and drivetrain applications.

Tool and Die Steels in Automotive Manufacturing

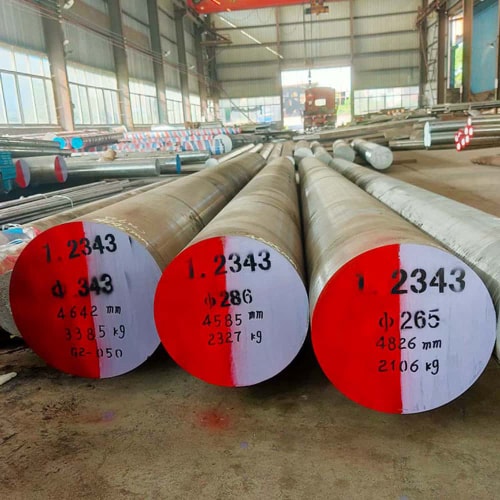

Common Grades: D2, D3, A2, D6, H11, M2

These are high-grade tool steels used in automotive stamping dies, molds, and machining tools. They provide high hardness, wear resistance, and thermal stability, enabling precise and durable production of automotive components.

D2/D3

High-carbon, high-chromium tool steel for cutting dies and heavy stamping.

A2

Air-hardening, impact-resistant steel for molds and dies.

D6

High-strength die steel for heavy-duty forming operations.

H11

Hot-work steel for dies operating at elevated temperatures.

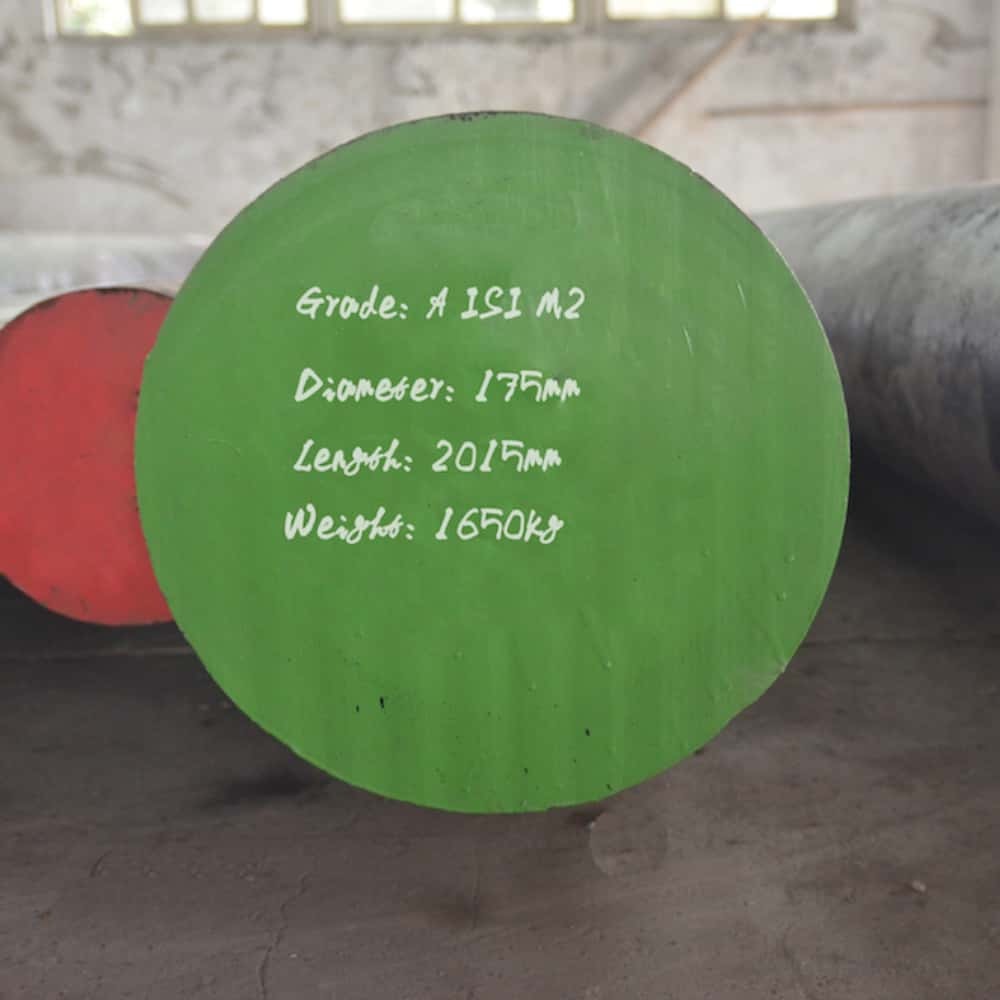

M2

High-speed steel for machining critical engine and drivetrain components.

Material Composition and Properties

Key Alloying Elements and Their Effects

| Element | Function | Benefit for Automotive Applications |

|---|---|---|

| Chromium (Cr) | Increases hardness and wear resistance | Ideal for gears and structural components |

| Nickel (Ni) | Enhances toughness and ductility | Improves crash resistance and fatigue life |

| Molybdenum (Mo) | Boosts high-temperature strength | Critical for engine and exhaust components |

| Vanadium (V) | Refines grain structure | Improves strength and wear resistance |

| Silicon (Si) | Oxidation resistance | Enhances durability under heat and stress |

Mechanical Properties of Automotive Alloy Steel

- Tensile Strength: Ensures the steel withstands pulling and bending forces.

- Yield Strength: Determines the limit before permanent deformation occurs.

- Hardness: Resistance to surface wear and abrasion.

- Impact Toughness: Critical for safety-related components under dynamic load.

Standards and Specifications

Automotive alloy steels comply with ASTM, EN, GB, ISO, ensuring uniformity, safety, and performance across global automotive applications.

Manufacturing and Processing

Raw Material Selection

Steel billets, slabs, and coils are carefully selected based on alloy composition, cleanliness, and mechanical requirements.

Forming and Shaping Processes

- Hot Rolling: Provides ductility and toughness for large components.

- Cold Drawing: Ensures precise dimensions and smooth surfaces for suspension and drivetrain parts.

- Forging & Extrusion: Creates high-strength components like crankshafts and connecting rods.

Heat Treatment

Processes like quenching, tempering, annealing, and normalizing optimize hardness, toughness, and fatigue resistance for specific automotive applications.

Surface Treatment

- Coating and plating: Galvanization or phosphating to prevent corrosion

- Polishing and hardening: Improve wear resistance for engine and drivetrain components

Quality Control

Automotive alloy steels undergo rigorous mechanical testing, chemical analysis, non-destructive testing (NDT), and microstructure inspections to ensure reliability and compliance with automotive standards.

Typical Automotive Applications

Structural and Chassis Components

A-pillars, B-pillars, cross members, and suspension arms require high-strength automotive alloy steel for crash safety and durability.

Engine Components

Crankshafts, connecting rods, gears, and camshafts use tool steels like D2, M2, and H11 to resist wear and high temperatures.

Transmission and Drivetrain

Gears, shafts, and bearings benefit from high-strength and wear-resistant alloy steels to ensure smooth operation and long lifespan.

Body Panels and Exhaust Systems

Corrosion-resistant alloy steels provide protection against rust, chemicals, and heat exposure.

Quality Standards and Certification

Domestic Standards

GB/T 3077, GB/T 8163 for structural and alloy steel applications in vehicles

International Standards

ASTM A29, EN 10083 for alloy steel chemical and mechanical properties

Testing and Traceability

- Chemical composition analysis ensures proper alloying

- Mechanical testing validates tensile, yield, and hardness

- Batch traceability maintains quality throughout the supply chain

Comparison and Selection Guide

| Feature | Automotive Alloy Steel | Carbon Steel |

|---|---|---|

| Strength | High, customizable | Moderate |

| Wear Resistance | Excellent | Limited |

| Corrosion Resistance | Alloyed/coated | Poor |

| Application | Engine, chassis, drivetrain | General structural parts |

| Cost | Higher | Lower |

Key Selection Considerations

- Safety requirements and crash performance

- Wear and corrosion resistance for engine and drivetrain

- Manufacturing process compatibility (forging, stamping, machining)

- Weight and fuel efficiency considerations

- Cost and budget constraints

Future Trends and Innovations

Lightweight High-Strength Alloy Steels

Development of advanced high-strength steels (AHSS) for fuel efficiency and emissions reduction.

High-Performance Tool and Die Steels

Improved grades for dies, molds, and cutting tools, enhancing durability and precision in automotive production.

Advanced Manufacturing Technologies

Automated forging, CNC machining, and intelligent heat treatment improve consistency, precision, and efficiency.

Sustainable and Recyclable Materials

Recycling alloy steels and using low-carbon manufacturing reduce environmental impact in automotive production.

Conclusion

Automotive alloy steel is the backbone of modern vehicle manufacturing, combining strength, durability, wear resistance, and safety. By understanding material types, tool steels, manufacturing processes, and applications, engineers can optimize vehicle performance while balancing cost and weight. Ongoing innovations in high-strength steels, tool steels, and sustainable processes ensure that automotive alloy steel will continue to play a critical role in shaping the future of the automotive industry.

FAQ

What is automotive alloy steel used for in cars?

It is used in chassis, suspension, drivetrain, engine components, and safety-critical structures.

How does automotive alloy steel differ from regular steel?

It offers higher strength, wear resistance, corrosion resistance, and better fatigue performance, making it suitable for demanding automotive applications.

Why is high-strength steel important for car safety?

High-strength alloy steel absorbs crash energy better, preventing deformation and protecting occupants during collisions.

Can automotive alloy steel resist corrosion and wear?

Yes, alloying elements like Cr, Ni, Mo and surface coatings improve resistance to corrosion, wear, and heat.

How do heat treatments affect performance?

Processes like quenching, tempering, and annealing optimize hardness, toughness, and fatigue resistance for each component’s specific needs.

What tool steels are used in automotive manufacturing?

Common grades include D2, D3, A2, D6, H11, and M2, primarily for dies, molds, and machining tools that require high wear resistance and precision.

How to choose the right automotive alloy steel?

Consider application requirements, mechanical properties, corrosion resistance, manufacturability, and cost to select the proper grade.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀