Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Blog Key Points

- Introduction to A2 vs O1 steel decision

- Chemical composition and engineering properties

- Detailed cost analysis and lifecycle considerations

- Performance comparison: wear, toughness, hardness, edge retention

- Heat treatment and practical processing tips

- Industrial applications and real-world use cases

- Design and engineering considerations

- Industry expert opinions and data insights

- Maintenance, safety, and value analysis

- FAQ answering common search queries

Introduction

Choosing between A2 and O1 steel is more than picking materials — it’s about balancing cost, performance, machinability, and long-term value for your specific project needs. Whether you’re a toolmaker, knife craftsman, or industrial engineer, understanding how these two cold work tool steels differ at both metallurgical and cost levels will influence your decision on everything from prototype tooling to high-volume production. This guide dives into why price and performance matter and how to choose the right steel based on real engineering demands.

Understanding Material Fundamentals

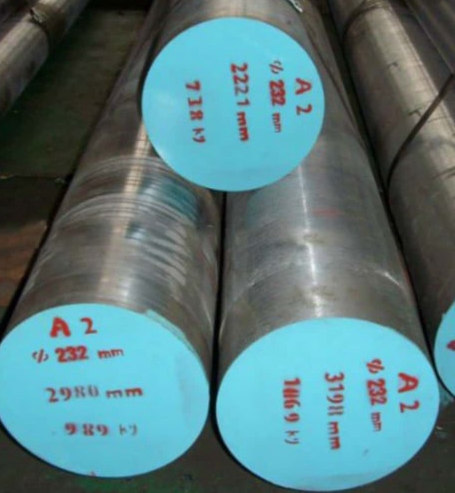

What Makes A2 Tool Steel Unique?

A2 steel is an air-hardening cold work tool steel known for its excellent dimensional stability during heat treatment, high wear resistance, and strong toughness — making it suitable for demanding dies and heavy-duty tooling.

Key Characteristics:

- Air hardening: Reduces distortion after heat treatment.

- Chromium content: Typically 4.75–5.50%, improving wear resistance.

- Balanced composition provides enhanced abrasion resistance and toughness.

A2’s chemistry enables it to maintain consistent performance in high-load environments where precision and durability matter most.

What Defines O1 Tool Steel?

O1 steel is an oil-hardening tool steel with a simpler alloy balance focused on machinability, edge sharpness, and cost efficiency.

Key Features:

- Oil hardening: Slower cooling that minimizes cracking risk but may introduce slight distortion in larger sections.

- Carbon content: Typically 0.90–1.00%, enhancing hardness and edge sharpness.

- Easier machining: O1 is widely valued for its fine grain structure and ease of shaping before hardening.

O1’s properties make it a popular choice where precision, sharpenability, and cost control are priorities.

Chemical Composition and Material Properties

Comparing Alloy Elements

Understanding the alloying differences between A2 and O1 helps explain their performance nuances:

| Element | A2 Steel (%) | O1 Steel (%) | Impact |

|---|---|---|---|

| Carbon (C) | ~0.95–1.05 | ~0.90–1.00 | Determines hardness potential |

| Chromium (Cr) | 4.75–5.50 | 0.40–0.60 | A2 has significantly higher wear resistance |

| Molybdenum (Mo) | ~0.90–1.40 | — | Increases temper resistance in A2 |

| Vanadium (V) | 0.15–0.30 | ≤0.30 | Grain refinement and wear resistance |

| Manganese (Mn) | ≤1.00 | ~1.00–1.20 | Improves hardenability in both steels |

This composition table demonstrates why A2 generally offers higher wear resistance and toughness, while O1 maintains ease of machining and sharper edges for less demanding cutting tasks.

Mechanical Properties Overview

Both steels can reach high hardness after proper heat treatment, but each has distinct performance characteristics:

| Property | A2 Tool Steel | O1 Tool Steel |

|---|---|---|

| Hardened Rockwell C | ~58–63 HRC | ~57–62 HRC |

| Dimensional Stability | Excellent | Good |

| Toughness | High | Moderate–High |

| Wear Resistance | Better | Good |

| Machinability | Moderate | Easier |

A2’s alloying produces a matrix that better balances abrasion resistance and strength, whereas O1’s simpler composition facilitates sharper edges and faster machining.

Cost Analysis: A2 vs O1 Steel

Material Cost Differences

When budgeting for tool steels, raw material price is just one part of the equation. Generally:

- O1 steel raw bars are priced lower due to simpler alloying.

- A2 steel often costs more because of additional alloy elements like chromium and molybdenum.

This cost difference reflects upfront pricing and the complexity of processing, primarily due to A2’s enhanced performance features.

Lifecycle Value and Total Ownership Cost

Comparing lifetime cost requires factoring in:

- Tool longevity: A2 tools often require less frequent replacement due to superior wear resistance.

- Maintenance frequency: O1 may need sharpening and maintenance more often in heavy wear environments.

- Production downtime: Tool failure can be costly in high‑volume manufacturing.

In many industrial settings, A2’s higher initial cost can yield lower total cost of ownership when used in high‑stress tooling applications.

Performance Comparison

Wear Resistance and Edge Retention

A2 steel’s higher chromium and molybdenum content form stable carbides that help resist wear over long service periods. In contrast, O1’s composition allows it to be sharpened easily, but it dulls faster under heavy use.

Toughness and Shock Resistance

While both steels deliver good strength, A2 typically shows higher toughness and resistance to chipping or cracking in demanding conditions, making it suitable for heavier tooling tasks. O1, with its balanced carbon and manganese, remains adequate for moderate work but is less ideal for repetitive high‑impact usage.

Hardness and Dimensional Stability

Both grades are capable of reaching similar hardness ranges after proper heat treatment, but A2’s air‑hardening mechanism means less distortion during heat treatment — an advantage when dimensional accuracy is critical.

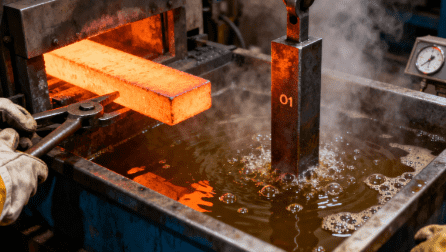

Heat Treatment and Processing

Hardening Methods

- A2 Tool Steel: Air‑hardening at high temperatures (≈ 1020–1040 °C) reduces distortion and improves uniformity.

- O1 Tool Steel: Oil quenching offers efficient hardening and a fine grain structure but can increase distortion risk in larger sections.

Tempering Strategies

Both steels benefit from controlled tempering cycles to achieve a balance of hardness and toughness:

- A2 typically tempering to ~510 °C helps develop secondary hardening and toughness.

- O1 tempering is tuned more toward optimizing edge sharpness and cutting performance after quench.

Adequate tempering is critical to prevent brittleness while maximizing wear resistance.

Industrial Applications and Use Cases

When to Choose A2 Steel

A2’s balanced properties make it ideal for:

- Precision dies and punches in heavy stamping operations.

- Shear blades and industrial cutting tools requiring long lives.

- High‑volume production components where dimensional stability post‑heat treat is essential.

When O1 Steel Shines

O1 remains preferred for:

- Custom knives and small cutting tools where sharpness and ease of grinding matter.

- Precision tooling with frequent adjustments due to simpler machining.

- Projects where budget and turnaround time are top priorities.

Design and Engineering Considerations

Load Profiles and Impact Conditions

Selecting the right tool steel requires analyzing how your part will be used. A2 is better for high‑stress heavy loads, while O1 excels where precision cutting and quick maintenance matter.

Geometric Complexity and Machinability

O1’s fine grain and machinability reduce tooling time, beneficial for intricate components. A2’s harder material demands specialized tooling but gives consistent final dimensions.

Industry Expert Insights

Seasoned toolmakers often emphasize that the quality of heat treatment matters as much as the steel grade. Proper cycles and tempering can significantly influence performance regardless of whether you choose A2 or O1. Real‑world practitioners note that while O1 is easier to sharpen in the field, A2’s edge retention and toughness often make it worth the extra processing effort.

Maintenance, Safety & Value

Maintenance Best Practices

Both steels require regular inspection for wear and micro‑cracks. High alloy steels should be protected from corrosion with appropriate coatings or storage conditions to maximize service life.

Safety Considerations

Ensure that heat treatment and machining operations are performed with controlled processes to avoid cracking or excessive warping, particularly in A2 due to its higher alloy content.

Conclusion

Choosing between A2 vs O1 steel isn’t just about initial cost — it’s about matching material properties, heat treatment behavior, performance under stress, and long‑term value to your project goals. A2 excels in demanding, high‑stress environments, while O1 provides cost‑effective, machinable options for precision work. Thoughtful selection ensures your tooling performs optimally over its service life.

FAQ

Which is better for high‑impact tools?

A2 typically offers higher toughness and wear resistance in high‑impact applications, while O1 is better for light to moderate use.

Is O1 steel easier to machine than A2?

Yes — O1’s composition and grain structure make it easier to machine and shape before heat treatment.

Which cost less, A2 or O1?

O1 is generally less expensive upfront due to simpler alloying, while A2’s higher performance may reduce long‑term costs through extended service life.

Can both steels achieve similar hardness?

Yes — both can be hardened within similar ranges (~57–63 HRC) with proper heat treatment, though A2’s air‑hardening leads to better dimensional stability.

Which is better for custom knives?

O1’s ability to take and hold a fine edge makes it popular in knife making, though A2 also performs well with proper tempering.