Table of Contents

Introduction

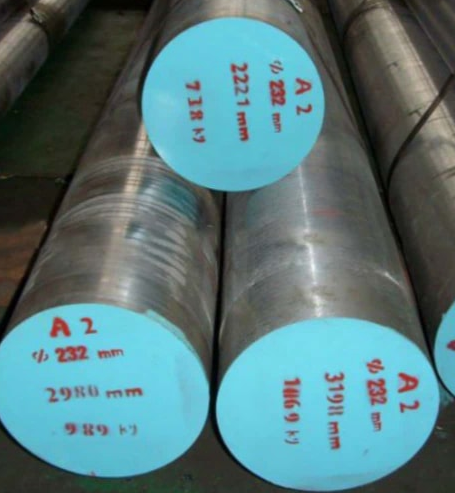

A2 tool steel is widely used in tool-making industries due to its balance of toughness, machinability, and wear resistance. One of the key considerations for manufacturers and machinists is a2 tool steel hardness before heat treat, which directly impacts how easy the steel is to machine and shape.

In this guide, we will explore the raw hardness of A2 steel, factors affecting it, its mechanical properties compared to heat-treated steel, and practical tips for machining and application. By the end, you’ll have a clear understanding of how to handle and work with A2 billets effectively.

What Is A2 Tool Steel?

Definition and Classification

A2 tool steel is a medium-carbon, high-chromium air-hardening cold work tool steel. It is designed to provide a balance between toughness, wear resistance, and machinability, making it ideal for cutting tools, dies, and punches.

Alloy Composition

The steel contains carbon, chromium, molybdenum, and vanadium, each contributing to hardness, wear resistance, and toughness. Pre-heat treat billets usually have a moderate carbon content that ensures machinability.

Applications

- Cold work dies and cutting tools

- Punches and dies

- Precision measurement tools

- Components requiring complex shapes and close tolerances

Advantages of Pre-Heat Treat A2 Steel

- Moderate hardness makes machining easier and safer.

- High toughness reduces the risk of cracking during cutting or milling.

- Uniform hardness ensures predictable and consistent results in manufacturing.

A2 Tool Steel Hardness Before Heat Treat

Typical Pre-Heat Treat Hardness

- In its raw, pre-heat treat state, A2 tool steel typically measures around 190–220 HB (Brinell Hardness).

- This hardness range is optimal for machining, allowing for cutting, drilling, and milling without excessive wear on tools.

Importance of Pre-Heat Treat Hardness

- Provides enough toughness to prevent cracking or chipping during processing.

- Ensures efficient material removal and smoother finishing.

- Offers dimensional stability during complex machining operations.

Factors Affecting Pre-Heat Treat Hardness

Alloy Composition

- Variations in carbon and chromium content influence baseline hardness. Higher carbon slightly increases hardness but can reduce machinability.

Forging or Casting Method

- Steel billets forged or rolled have finer and more uniform grains, improving both hardness consistency and toughness.

Cooling Rate After Forging

- Faster cooling may slightly increase hardness, but pre-heat treat steel hardness remains relatively stable.

Comparison

Hardness Increase After Heat Treatment

- After hardening and tempering, A2 steel can achieve 56–62 HRC, significantly enhancing wear resistance.

- Pre-heat treat hardness is much lower but ensures ease of machining before reaching final hardness.

Mechanical Properties Comparison Table

| Property | A2 Steel Pre-Heat Treat | A2 Steel After Heat Treat |

|---|---|---|

| Hardness | 190–220 HB | 56–62 HRC |

| Toughness | High | Moderate |

| Machinability | Excellent | Moderate–Low |

| Wear Resistance | Low | High |

| Formability | High | Low |

Insight: Raw A2 billets provide excellent machinability and toughness, while heat treatment maximizes hardness and wear resistance for long-term use.

Processing Advantages of A2 Tool Steel Pre-Heat Treat

Machinability

- Pre-heat treat A2 steel is ideal for milling, turning, drilling, and grinding.

- Moderate hardness minimizes tool wear and allows for more precise cuts.

Reduced Risk of Cracking

- High ductility reduces the likelihood of cracking under stress.

- This makes it safer for complex or intricate parts.

Dimensional Accuracy

- Uniform pre-heat treat hardness ensures consistent machining results.

- Easier to maintain tight tolerances during fabrication.

Cost and Efficiency Benefits

- Reduces production time and tooling costs.

- Minimizes material waste and machining errors.

Practical Tips for Working with Pre-Heat Treat A2 Steel

Cutting and Milling Recommendations

- Use cutting fluids to reduce heat and friction.

- Employ high-speed steel or carbide tools for optimal results.

Drilling and Tapping Tips

- Pre-drill pilot holes for larger or threaded parts.

- Avoid aggressive feed rates to prevent local hardening.

Pre-Heat Treat Inspection

- Check billets for uniform hardness and surface defects.

- Ensure hardness stays within 190–220 HB for predictable machining performance.

Applications and Recommendations

For Machining and Tool Making

- Use pre-heat treat billets for milling, turning, and drilling.

- Achieve precise shapes before hardening for wear resistance.

For Complex or High-Precision Parts

- Pre-heat treat hardness ensures minimal tool wear, smooth surfaces, and dimensional stability.

- After machining, perform proper heat treatment to reach final hardness and durability.

Conclusion

- Pre-heat treat A2 steel provides an ideal balance of machinability, toughness, and uniform hardness, making it perfect for shaping and forming complex tools.

- Heat treatment dramatically increases hardness and wear resistance for long-term performance.

- Choosing high-quality A2 billets ensures efficient machining, precise dimensions, and superior final properties.

In short: A2 tool steel hardness before heat treat is the key to easy machining, while heat treatment unlocks its full potential for durability and wear resistance.

FAQ

What is the hardness of A2 steel before heat treatment?

Around 190–220 HB, ideal for machining and forming without excessive tool wear.

Can you machine A2 steel after heat treatment?

Machining after hardening is more difficult due to increased hardness; pre-heat treat machining is recommended.

Why is pre-heat treat hardness important?

Ensures smooth machining while maintaining toughness and preventing cracks.

Does pre-heat treat A2 steel crack during machining?

Rarely, due to its high ductility and toughness in raw billet form.

How does alloy composition affect pre-heat treat hardness?

Higher carbon and chromium slightly increase baseline hardness but can reduce machinability if excessive.

Is it better to buy raw billets or pre-hardened A2 steel?

Raw billets are preferred for complex machining; pre-hardened steel is suitable for parts requiring minimal machining.

Can heat treatment change the uniformity of hardness?

Properly performed heat treatment enhances wear resistance while maintaining uniformity throughout the part.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀