Whether you’re crafting a DIY project at home, working on a small workshop job, or diving into some serious metalworking tasks, choosing the right tool steel can make a huge difference in your results.Hot Work Tool Steel and Cold Work Tool Steelare two common materials used in tool manufacturing, each with its unique features and applications. But how do you know which one is right for you? Let’s break it down.

Table of Contents

What is Hot Work Tool Steel?

Imagine you’re working with molten metal, forging a piece of metal into a new shape, or even creating custom molds for casting. In these scenarios, you need a tool steel that can withstand extreme temperatures and keep working, no matter how hot things get. That’s where Hot Work Tool Steel comes in.

Hot work tool steel is designed to endure high temperatures, making it perfect for processes like forging, casting, and stamping under heat. If you’re crafting tools or molds that will face the heat of molten metals, this is your material of choice.

Key Features of Hot Work Tool Steel:

- Heat Resistance: Picture yourself working with molten metal in a foundry. Hot work tool steel can maintain its strength and hardness even under extreme heat, ensuring your tools won’t lose their shape or performance.

- Thermal Fatigue Resistance: Hot work tool steel can handle the cycle of heating and cooling without cracking, much like a sturdy frying pan that handles high heat and cooling without warping.

- Impact Resistance: Let’s say you’re hammering or pressing metal at high temperatures. Hot work tool steel can take those heavy impacts without breaking, making it perfect for forging tools.

- Wear Resistance: Despite the high heat, hot work tool steel resists wear and tear, allowing your tools to last longer under tough conditions.

When to Use Hot Work Tool Steel?

Hot work tool steel is your best choice when tools are exposed to high temperatures during tasks like:

- Casting: Think of creating molds for pouring molten metal or even making custom sculptures from cast metal. Hot work tool steel can handle the intense heat of molten metal without warping or losing its strength.

- Forging: If you’re hammering, pressing, or shaping metal under heat (like blacksmithing), hot work tool steel is ideal for tools that need to withstand both pressure and heat.

- High-Temperature Stamping: For industries or workshops that need stamping tools that can handle heat, hot work tool steel ensures longevity and reliability.

- Mold Manufacturing: If you’re making precision molds for casting aluminum or copper alloys, hot work tool steel’s heat resistance and wear durability will make sure your molds last.

What is Cold Work Tool Steel?

Imagine you’re working on a metal cutting project, say, creating a custom knife or shaping some metal parts. You need a steel that can withstand wear and tear without dulling too quickly. This is where Cold Work Tool Steel comes in. It’s made to perform in normal (room) temperatures and is designed to keep your tools sharp for long periods, even under heavy use.

Whether you’re a hobbyist crafting metal parts in your garage or a small workshop owner making precision tools, cold work tool steel is your go-to for cutting, stamping, and shaping tools that need to maintain sharpness.

When to Use Cold Work Tool Steel?

Cold work tool steel is perfect for projects where tools are exposed to high stress at room temperature. Some examples include:

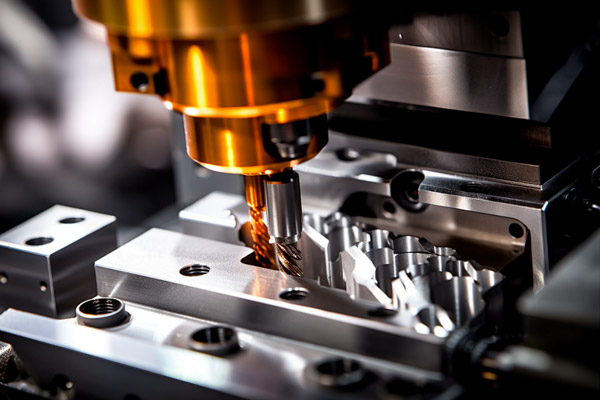

- Cutting Tools: If you’re working with metal cutting, think drill bits, turning tools, or milling cutters.

- Stamping Dies: If you’re stamping patterns or shapes into metal, cold work tool steel keeps your dies sharp and durable.

- Forming Tools: For molding metal, whether you’re creating custom parts or DIY molds, cold work tool steel ensures precision.

- Punching Tools: If you’re making holes in tough materials, cold work tool steel is ideal for cold punches that need to last.

How to Choose the Right Tool Steel for Your Project

Now that you know the differences, it’s time to figure out which steel is the best for your specific project.

- Cold Work Tool Steel is best for tools that need to maintain sharpness and perform under room temperature conditions. It’s the perfect choice for DIY enthusiasts or small workshops that need durable tools for cutting, stamping, and forming at regular temperatures.

- Hot Work Tool Steel is designed for environments where extreme heat is involved. If you’re working on projects that require handling molten metals or forging, this is the material that will keep your tools strong, resistant to heat, and ready to endure high-pressure tasks.

Conclusion: Get the Most Out of Your Tools

Cold Work Tool Steel helps you create sharp, durable tools that stand the test of time for projects at room temperature, while Hot Work Tool Steel keeps your tools strong and reliable even when things get extremely hot. By understanding the key differences between these two types of steel, you can make the best choice for your needs—and keep your projects running smoothly!