Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

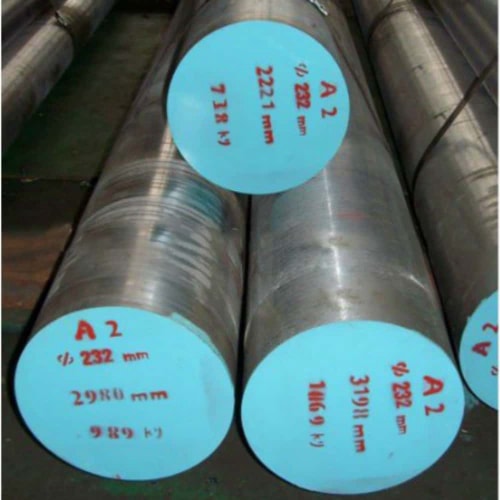

A2 tool steel is one of the most versatile air-hardening tool steels widely used in industrial applications. Known for its excellent toughness, wear resistance, and dimensional stability, a2 tool steel is commonly applied in the manufacturing of dies, punches, shear blades, and cutting tools. Engineers and manufacturers rely on its predictable performance under various processing and heat treatment conditions.

Understanding the essential properties of a2 tool steel is crucial for selecting the right material for specific industrial applications. These properties influence machinability, heat treatment response, service life, and overall operational efficiency. This article delves into six key properties of a2 tool steel, providing practical insights for industrial use, quality assurance, and performance optimization.

1. Hardness and Heat Treatment of A2 Tool Steel

One of the most critical properties of a2 tool steel is its hardness. Typically, the steel can achieve high hardness values after proper heat treatment, which includes austenitizing, air cooling, and tempering. The typical Rockwell hardness range for hardened and tempered a2 tool steel is 58-62 HRC, depending on the application and tempering conditions.

The hardness of a2 tool steel is essential for wear resistance, edge retention, and dimensional stability. Proper heat treatment ensures that the steel maintains its mechanical properties while reducing the risk of cracks or distortion. This property makes it suitable for high-precision tooling, where consistent hardness is crucial for performance and longevity.

Key considerations for heat treatment include:

- Controlled heating rates to prevent thermal stress

- Air-hardening characteristics that minimize distortion

- Proper tempering to balance toughness and hardness

2. Toughness and Impact Resistance of A2 Tool Steel

Toughness is another defining property of a2 tool steel. While achieving high hardness is important, excessive brittleness can lead to premature tool failure. A2 tool steel offers a well-balanced combination of hardness and toughness, making it capable of withstanding moderate impact and shock loads without chipping or breaking.

Impact resistance is particularly valuable for applications such as punches, dies, and shear blades, where sudden loading or mechanical shocks occur. The alloying elements in a2 tool steel, including carbon, chromium, molybdenum, and vanadium, contribute to its capacity to resist crack propagation while maintaining wear resistance.

Engineers must consider both hardness and toughness when designing tools, ensuring that a2 tool steel can handle operational stresses without compromising service life.

3. Wear Resistance of A2 Tool Steel

Wear resistance is critical for any tool steel, and a2 tool steel demonstrates excellent performance in this regard. Its ability to resist abrasive wear, adhesive wear, and galling extends tool life and reduces maintenance costs.

The wear resistance of a2 tool steel can be enhanced through:

- Optimized heat treatment

- Surface hardening techniques, if necessary

- Proper tool design to distribute stress evenly

A2 tool steel is commonly used in applications that involve repeated cutting, stamping, or shearing, where surface degradation can compromise part quality. Its wear resistance makes it suitable for long production runs and high-volume manufacturing environments.

4. Dimensional Stability and Machinability of A2 Tool Steel

Dimensional stability refers to the ability of a2 tool steel to retain its shape and size during heat treatment, machining, and service. Air-hardening a2 tool steel exhibits minimal distortion, which is particularly important for precision dies, molds, and cutting tools where tight tolerances are required.

Machinability is another key factor. While a2 tool steel is harder than many general-purpose steels, it can still be machined effectively in annealed condition. Manufacturers often perform rough machining before heat treatment and finish machining after tempering to achieve optimal dimensional accuracy.

The combination of stability and machinability allows for precise tooling production with reduced scrap rates and consistent performance across multiple parts.

5. Corrosion Resistance and Stability in Service

A2 tool steel is not classified as stainless, but its chromium content provides moderate corrosion resistance. While not suitable for highly corrosive environments, it can withstand normal humidity, light oils, and occasional exposure to mild chemicals without significant degradation.

Regular maintenance and proper storage are essential to preserve its properties. Applications that require occasional exposure to moisture or lubricants can still benefit from a2 tool steel’s durability, as its surface hardness and toughness prevent rapid wear or corrosion-induced failures.

Table: Summary of Key Properties of A2 Tool Steel

| Property | Description | Industrial Relevance |

|---|---|---|

| Hardness | 58-62 HRC after heat treatment | Wear resistance, cutting performance |

| Toughness | High impact resistance | Suitable for punches, dies, and shear blades |

| Wear Resistance | Excellent against abrasive/adhesive wear | Extended tool life, low maintenance |

| Dimensional Stability | Minimal distortion during heat treatment | High-precision dies and molds |

| Machinability | Good in annealed condition | Efficient machining before and after heat treatment |

| Corrosion Resistance | Moderate | Suitable for controlled industrial environments |

6. Thermal Conductivity and Heat Resistance

Thermal properties of a2 tool steel impact its performance during cutting, stamping, and molding operations. Adequate thermal conductivity allows the steel to dissipate heat efficiently, preventing localized overheating and reducing the risk of temper softening during service.

Heat resistance is critical for tools subjected to high-temperature operations. A2 tool steel maintains hardness and dimensional stability under elevated temperatures, which makes it ideal for industrial tools and dies that encounter friction or thermal cycling.

Applications of A2 Tool Steel in Industry

A2 tool steel is widely used across multiple sectors due to its balanced combination of hardness, toughness, and wear resistance. Typical applications include:

- Die and mold making: Stamping dies, forging dies, and precision molds

- Cutting tools: Shear blades, punches, and trimming tools

- Industrial knives: Paper, cardboard, and food processing blades

- Components subject to shock and wear: Guide plates, pins, and wear inserts

Its versatility allows manufacturers to standardize tool production while maintaining high performance across diverse operations.

Operational Tips for Maximizing A2 Tool Steel Performance

To achieve the best results with a2 tool steel:

- Always anneal before rough machining

- Perform controlled heat treatment cycles to achieve desired hardness and toughness

- Temper appropriately to reduce residual stress

- Store in dry environments to prevent surface rust

- Use lubricants and cooling fluids during high-speed cutting to extend tool life

Proper handling and treatment maximize service life, minimize maintenance, and ensure consistent industrial performance.

Conclusion

A2 tool steel is a versatile and reliable material widely used in industrial tooling. Its hardness, toughness, wear resistance, dimensional stability, machinability, and moderate corrosion resistance make it suitable for dies, punches, shear blades, and other high-precision tools. Understanding these six essential properties allows engineers and manufacturers to optimize heat treatment, machining, and operational practices, ensuring maximum performance and longevity.

By integrating proper pre-machining, heat treatment, and maintenance protocols, a2 tool steel can provide consistent results in demanding industrial environments. Its balanced properties make it a go-to choice for applications where both durability and precision are critical.

FAQ

1. What is the typical hardness of a2 tool steel?

After proper heat treatment, a2 tool steel usually reaches 58-62 HRC.

2. Is a2 tool steel tough enough for impact applications?

Yes, it offers high toughness suitable for dies, punches, and shear blades.

3. Can a2 tool steel be machined easily?

It is machinable in annealed condition; final machining after heat treatment ensures precision.

4. Does a2 tool steel resist corrosion?

It has moderate corrosion resistance due to chromium content, suitable for controlled industrial environments.

5. What are the main industrial applications of a2 tool steel?

A2 tool steel is used in dies, molds, cutting tools, shear blades, and components exposed to wear and shock.