Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

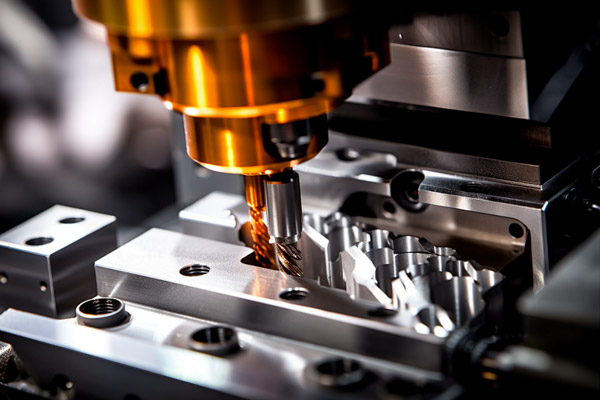

The comparison of SKD11 vs D2 vs Cr12MoV is one of the most frequently discussed topics in the global tool steel industry. These three high-carbon, high-chromium cold-work tool steels are crucial in stamping dies, punching tools, industrial blades, metal forming tools, and precision components.

Although they belong to the same metallurgical family, their subtle differences in composition, carbide distribution, refinement quality, toughness, and stability lead to very different behaviors in real-world manufacturing environments.

This extended guide is designed to help engineers, procurement specialists, and manufacturing professionals clearly understand the differences—through definitions, concepts, performance tables, deep analysis, and real case examples.

Understanding Their Metal Class: High-Carbon, High-Chromium Tool Steel

Concept — What Defines High-Carbon, High-Chromium Tool Steel?

High-carbon, high-chromium steels contain above-average carbon and chromium levels that create high levels of chromium carbides, strong wear resistance, ability to reach high hardness levels (HRC 56–62), and excellent edge retention under pressure or cutting. This makes them ideal for cold-work tools that repeatedly contact metal, plastic, paper, or composite materials under strong compressive forces.

Concept — Carbide Structures and Microstructural Behavior

Chromium carbide particles exist in different forms and sizes. Their distribution determines how resistant the tool is to abrasion, how easily it chips under impact, and how well it handles sliding wear. Among the three grades, D2 has the highest and largest carbide population, SKD11 has finer, evenly distributed carbides, and Cr12MoV has coarser carbides with more inclusions.

Concept — Refining Methods and Purity Differences

Purity defines toughness. More refined alloys reduce inclusions and increase fatigue performance. SKD11 typically has better ESR/VAR refining, D2 varies by manufacturer, and Cr12MoV is cost-optimized, resulting in higher inclusion content. This difference often explains why SKD11 outperforms Cr12MoV in complex tooling and long production runs.

Detailed Overview — SKD11 vs D2 vs Cr12MoV as Individual Materials

What Is SKD11? (JIS Japan Standard)

SKD11 is a premium-grade cold-work tool steel defined by high toughness, balanced wear resistance, excellent dimensional stability, and predictable heat-treatment response. It is widely used in high-precision and long-life tools such as progressive stamping dies, precision forming dies, high-load industrial blades, punches, inserts, and long-run production molds.

Key Concept — Dimensional Stability During Heat Treatment

SKD11 undergoes minimal distortion during quenching, making it ideal for complex dies that must maintain very tight tolerances.

What Is D2? (AISI American Standard)

D2 is a high-carbon, high-chromium tool steel famous for extremely high wear resistance, strong edge retention, and exceptional abrasive resistance. It is commonly found in shear blades, precision industrial knives, high-abrasion molds, cutting tools for paper, leather, plastics, and forming dies in harsh environments.

Key Concept — Carbide Bulk and Brittleness

D2’s microstructure contains large primary carbides, boosting wear resistance but reducing overall toughness. This makes D2 excellent for cutting, but less suitable for impact-heavy applications.

What Is Cr12MoV? (GB Chinese Standard)

Cr12MoV is a cost-effective cold-work tool steel featuring good hardness, acceptable wear resistance, and budget-friendly alloy content. It is widely used in medium-duty stamping, general-purpose punching, low- to moderate-load forming tools, and OEM manufacturing lines.

Key Concept — Cost Advantage vs Performance Envelope

Cr12MoV is not designed for extreme-duty conditions, but its economical price makes it highly valuable for industries with predictable loads and shorter life cycle expectations.

Expanded Technical Comparison Table (Core Parameters)

| Parameter | SKD11 (JIS) | D2 (AISI) | Cr12MoV (GB) |

|---|---|---|---|

| Carbon (C) | 1.4–1.6% | 1.5–1.6% | ~2.0% |

| Chromium (Cr) | 11–12% | 11–12% | 11–13% |

| Molybdenum (Mo) | 0.8–1.0% | 0.7–1.2% | 0.4–0.6% |

| Vanadium (V) | 0.2–0.5% | 0.7–1.1% | ~0.2% |

| Typical Hardness | 58–62 HRC | 58–62 HRC | 56–60 HRC |

| Wear Resistance | High | Very High | Medium |

| Toughness | High | Medium | Low |

| Purity Level | High | Medium | Low |

| Heat-Treat Stability | Very High | High | Medium |

| Cost Ranking | Medium | Medium-High | Low |

New Comparative Behavior Table (Application-Oriented Properties)

| Performance Metric | SKD11 | D2 | Cr12MoV |

|---|---|---|---|

| Resistance to Cracking | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ |

| Edge Retention | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Response to EDM Finishing | Good | Average | Good |

| Deformation After Heat Treatment | Very Low | Low | Medium |

| Suitability for Complex Geometries | Excellent | Average | Poor |

| Fatigue Strength | High | Medium | Low |

| Best Use Environment | High load / high precision | High abrasion tools | Cost-controlled production |

Performance Breakdown — Deep Metallurgical Insights

Wear Resistance: Carbide Strength and Abrasion Behavior

Wear resistance is the most noticeable difference among these steels. SKD11 provides balanced wear and toughness due to fine carbides. D2’s primary carbides outperform both SKD11 and Cr12MoV in abrasive environments. Cr12MoV offers adequate wear resistance for moderate-duty operations but will wear faster under heavy abrasive cycles.

Toughness and Crack Resistance

Toughness determines how well a steel absorbs impact or resists chipping. SKD11 has the best overall toughness due to finer carbides and better refining. D2 is moderately tough but brittle under sudden impact. Cr12MoV has the lowest toughness and is not recommended for high-impact tools.

Heat Treatment Behavior

SKD11 exhibits low distortion and predictable hardness, ideal for precision components. D2 is stable but may distort in thin or complex dies. Cr12MoV requires careful furnace control due to its chemical variability.

Expanded Real-World Case Studies

Case Study 1 — Automotive Stamping Die Lifespan Upgrade

A Tier-1 automotive supplier replaced Cr12MoV with SKD11 after repeated cracking issues. The previous tool life was ~300,000 cycles. After switching to SKD11, the die reached 1.2–1.5 million cycles, reducing unplanned downtime by 45%. This demonstrates SKD11’s superiority for high-cycle stamping.

Case Study 2 — Packaging Knife Upgrade from SKD11 to D2

A packaging manufacturer experienced dulling of SKD11 blades after short runs. Switching to D2 increased blade life by 55%, but required minor edge geometry adjustments to reduce chipping. D2’s dense carbides provided superior edge retention for abrasive materials.

Case Study 3 — Electronics Manufacturer Cost Reduction

A consumer electronics company replaced SKD11 with Cr12MoV for low-stress stamping. Tooling costs dropped by 20–25%, and performance remained adequate. Cr12MoV proved to be the best cost-effective choice for moderate-duty tasks.

Case Study 4 — Precision Punching Tool for Steel Sheets

D2 punches experienced cracking at the tip in high-tensile steel applications. Replacing D2 with SKD11 extended punch life by 30%, reduced micro-chipping, and lowered maintenance frequency. SKD11’s toughness handled high-impact punching better than D2.

Selection Concepts — Practical Guidance for Engineers

When long-term dimensional stability is required, use SKD11, ideal for high-precision dies that cannot tolerate distortion. When edge retention is the priority, use D2, excelling in abrasive cutting environments. When budget control is critical, use Cr12MoV, which provides the best cost-to-performance ratio. Carbide structure also matters: smaller, evenly distributed carbides (SKD11) increase toughness; large carbides (D2) increase wear resistance; coarse carbides with inclusions (Cr12MoV) reduce overall durability but are economical.

Conclusion

The comparison of SKD11 vs D2 vs Cr12MoV shows each steel has a distinct performance profile. SKD11 offers the best toughness and stability, D2 provides superior wear resistance, and Cr12MoV delivers cost efficiency. Consider load, geometry, cycle life, budget, and machining complexity when choosing.

If you’re unsure which grade fits your stamping die, industrial blade, or cold-work tooling application, our engineering team can help. We provide material selection consulting, heat treatment optimization, tool life improvement analysis, and failure diagnosis. Contact us for customized guidance tailored to your production environment.

FAQ

Is SKD11 better than D2?

It depends; SKD11 is tougher, D2 is more wear-resistant.

Can I replace D2 with SKD11 for cutting blades?

Yes, if impact resistance matters more than abrasive wear.

Does Cr12MoV deform more during heat treatment?

Yes, due to lower alloy stability.

Which steel is best for stamping thick metal sheets?

SKD11.

Which steel is most cost-effective?

Cr12MoV.

Which steel lasts longest under high-abrasion conditions?

D2 typically outperforms SKD11 and Cr12MoV due to its dense chromium carbides, making it ideal for cutting and shearing tools exposed to abrasive materials.

Can Cr12MoV be used for high-precision dies?

It can be used for moderate-precision applications, but SKD11 is preferred for high-precision and long-cycle dies because of its higher stability and toughness.

Why is D2 more prone to chipping than SKD11?

D2 contains large primary carbides, which increase wear resistance but reduce toughness, making it more susceptible to edge chipping under impact.