Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Tool steel is an essential material in manufacturing, offering high hardness, wear resistance, and thermal stability. Selecting the right type of tool steel is critical for achieving long-lasting tools, precise molds, and efficient machining processes. In this article, we explore the most common tool steel types, their applications, and key concepts to help engineers, designers, and buyers make informed decisions.

What Are Tool Steel Types?

Tool steel refers to specialized steels used for making tools and molds. They are designed to withstand high stress, retain hardness at elevated temperatures, and resist wear. Tool steels are generally classified based on their intended working conditions and manufacturing processes.

Key Properties of Tool Steel

- Hardness and Wear Resistance: Ensures long service life in cutting and forming applications.

- Toughness: Prevents cracking or chipping under heavy loads.

- Thermal Stability: Maintains performance at high temperatures, especially for hot work or high-speed applications.

Why Understanding Tool Steel Types Matters

Choosing the wrong steel can lead to premature wear, tool failure, or poor product quality. Understanding different tool steel types ensures better material selection, improved tool performance, and cost savings in production.

Cold Work Tool Steel

Cold work tool steel is used for tools operating at or near room temperature, such as stamping, cutting, and forming metal sheets. These steels offer high hardness and wear resistance suitable for precision shaping.

D2

D2 is a high-carbon, high-chromium steel known for its excellent wear resistance and good toughness. It is widely used for cutting tools, dies, and punches that require long service life under heavy use.

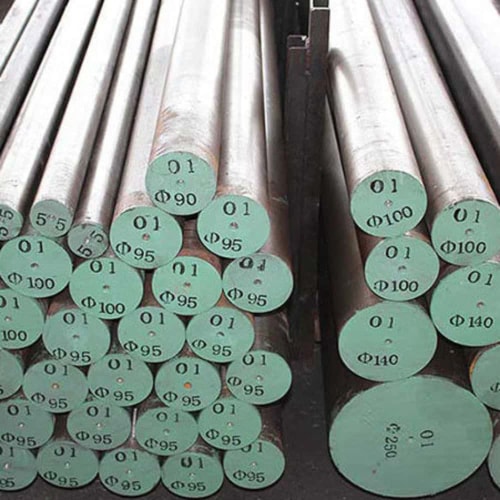

O1

O1 is an oil-hardening tool steel that is easy to machine and has good toughness. It is suitable for making dies, shear blades, and small punches, especially when moderate wear resistance is sufficient.

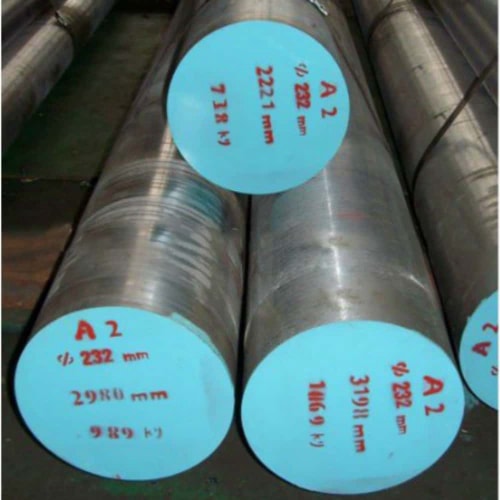

A2

A2 combines hardness with improved toughness, making it versatile for dies and forming tools. It can withstand moderate impact and retains its shape under stress.

D3

D3 is a high-chromium, high-carbon steel with superior wear resistance but slightly lower toughness than D2. It is often used for blanking dies and cutting tools with heavy abrasion.

S7

S7 is an air-hardening shock-resistant steel with good toughness and moderate wear resistance. It is ideal for tools that undergo impact or sudden loads, such as hammers and punches.

Hot Work Tool Steel

Hot work tool steel is designed for high-temperature operations such as forging, extrusion, and die casting. These steels maintain hardness and strength under elevated temperatures.

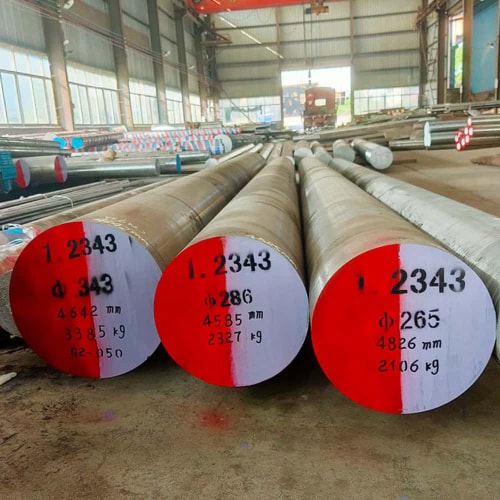

H13

H13 is a versatile hot work steel with excellent resistance to thermal fatigue and high-temperature strength. It is commonly used for die-casting molds, hot stamping dies, and extrusion tools.

H11

H11 offers good wear resistance and toughness at high temperatures. It is suitable for tools subjected to moderate thermal stress, including forging dies and hot forming molds.

H21

H21 is designed for applications requiring high-temperature durability and good toughness. It is often used in extrusion and die-casting molds where repeated heating and cooling occurs.

H10

H10 is a hot work steel that provides good hardness and thermal stability. It is often used for hot forging dies and tools that require moderate wear resistance.

H19

H19 combines toughness and heat resistance, suitable for larger hot forming dies and high-stress applications. It offers good resistance to thermal fatigue.

High-Speed Tool Steel (HSS)

High-speed steel is ideal for cutting tools that generate significant heat during operation. It retains hardness at high temperatures, ensuring long-lasting cutting performance.

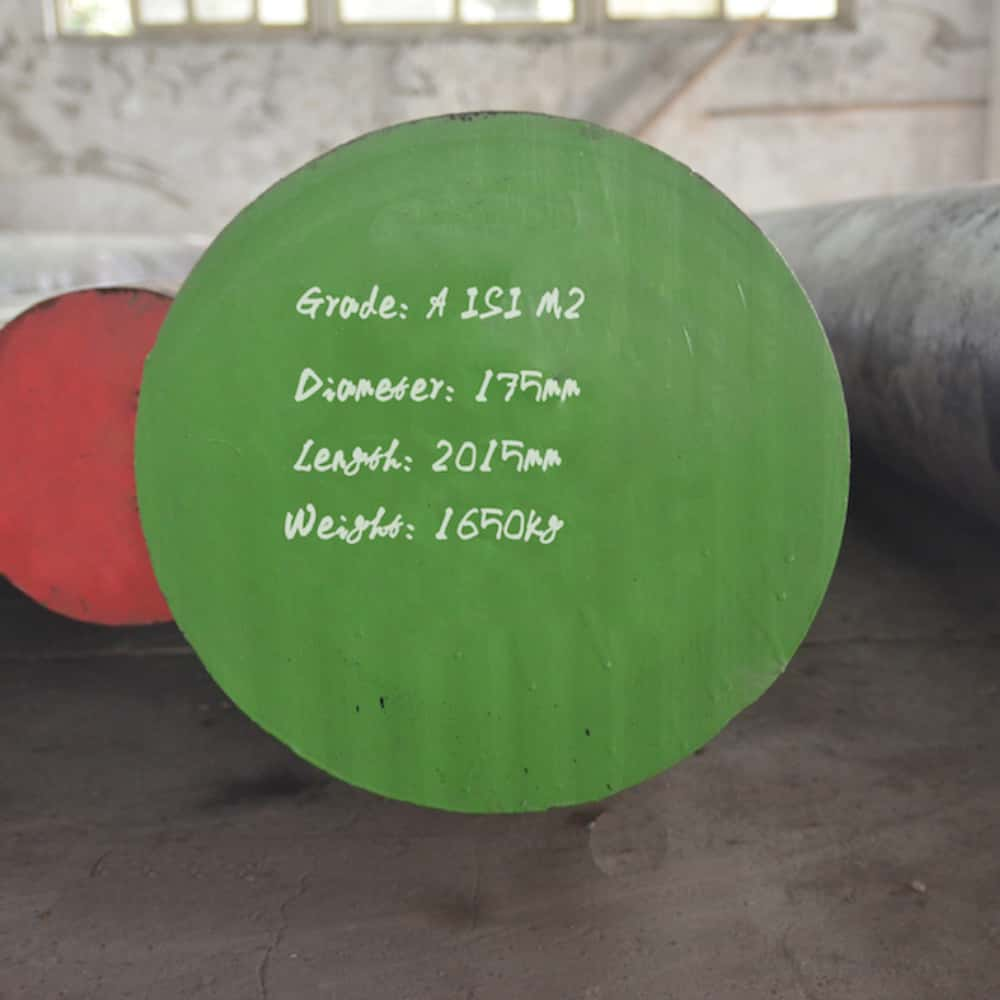

M2

M2 is a widely used general-purpose high-speed steel with excellent wear resistance and toughness. It is commonly applied in drill bits, milling cutters, and lathe tools.

M42

M42 contains higher cobalt content, which improves red-hardness and heat resistance. It is preferred for tools that must maintain cutting performance under prolonged high-speed operations.

T1

T1 is a tungsten-based high-speed steel offering high hardness and excellent cutting performance. It is suitable for heavy-duty drills and milling tools where precision and durability are critical.

M35

M35 is a high-speed steel with cobalt addition for better red-hardness and wear resistance. It is often used for twist drills and milling cutters in demanding applications.

M7

M7 is a molybdenum-type HSS with good toughness and wear resistance, suitable for high-speed cutting tools with moderate impact.

Plastic Mould Steel

Plastic mould steel is used for injection molding, blow molding, and other plastic processing molds. These steels emphasize polishability, corrosion resistance, and moderate wear resistance.

P20

P20 is a standard mold steel suitable for medium-volume injection molds. It provides good machinability, polishability, and wear resistance for general-purpose mold applications.

718H

718H offers higher hardness and corrosion resistance, making it ideal for complex molds with high precision requirements. It is commonly used in automotive, electronics, and high-performance molds.

S136

S136 is a stainless mold steel with excellent polishability and corrosion resistance. It is often used for molds requiring a high-gloss finish or for molding corrosive plastic materials.

1.2311 (P20 Modified)

1.2311 is a pre-hardened mold steel similar to P20 but easier to machine and polish, suitable for small- to medium-sized molds.

8407

8407 is a high-hardness, corrosion-resistant mold steel used for molds requiring high wear resistance and fine surface finish.

Comparing Plastic Mould Steel and Cold Work Steel

Plastic mold steels are designed for surface finish and corrosion resistance rather than extreme wear resistance. Cold work steels focus more on mechanical wear and high hardness.

Conclusion

Understanding tool steel types is essential for selecting the right material for any manufacturing process. By comparing cold work, hot work, high-speed, and plastic mold steels, engineers can choose the appropriate steel to improve durability, performance, and productivity. Proper selection and maintenance ensure long-lasting tools and high-quality results in any industrial application.