Table of Contents

Introduction

In the demanding world of tool and mold manufacturing, selecting the right steel is paramount. The performance of a component—its durability, precision, and longevity—hinges significantly on the material chosen. Among the myriad options, 8Cr13MoV and D2 steel frequently emerge as strong contenders, especially for applications requiring high wear resistance and a stable hardness profile. Both are renowned as micro-deformation cold work tool steels capable of achieving impressive hardness levels post-heat treatment. Yet, beneath their shared capabilities lie distinct chemical compositions and resulting performance characteristics that make one more suitable than the other for specific tasks.

This article delves into the core differences between 8Cr13MoV and D2 steel, uncovering the secrets of their hardness battle and guiding B2B buyers toward informed decisions for their projects.

Unveiling the Hardness Battle: 8Cr13MoV vs D2 Steel

Both 8Cr13MoV and D2 steel are air-hardening tool steels, meaning they can achieve high hardness simply by cooling in air after austenitizing. After heat treatment, both steels can reach a remarkable hardness of 60HRC. However, the path to this hardness and the properties that accompany it differ significantly due to their distinct elemental makeup.

Carbon Content: D2’s High Hardness & 8Cr13MoV’s Balance

Carbon content directly determines maximum hardness and wear resistance:

- D2 Steel:

- Carbon: ~1.5%

- High carbon forms abundant hard carbides, boosting wear resistance.

- Ideal for high-wear applications such as punching stainless steel sheets or high-hardness metals.

- 8Cr13MoV Steel:

- Carbon: 0.70–0.80%

- Achieves up to 60HRC hardness while maintaining a balanced toughness.

- Suitable for tools requiring moderate impact resistance and flexibility.

Regional Insight:

- In Europe, D2 is widely used for precision stamping dies due to strict durability standards.

- In China and Southeast Asia, 8Cr13MoV is popular for cost-effective tooling solutions in small- to medium-scale manufacturing.

Chromium’s Role in Attaining 60HRC Hardness

Chromium enhances hardness, wear resistance, and hardenability:

- 8Cr13MoV: 13–14.5% Cr

- Forms chromium carbides for improved wear resistance.

- Ensures corrosion resistance and balanced hardness.

- D2 Steel: 11.5–12% Cr

- High carbon + chromium combination makes D2 excellent for abrasive applications.

- Commonly used in Germany and Japan for punching stainless steel and high-precision molds.

Key Advantages of Chromium:

- Deep hardening for thicker sections.

- Enhanced corrosion resistance (especially for 8Cr13MoV).

- Increased wear resistance through carbide formation.

Molybdenum and Vanadium: Enhancing Wear Resistance and Toughness

These alloying elements differentiate performance significantly:

- 8Cr13MoV:

- Mo: 0.10–0.30%

- V: 0.10–0.25%

- Improves hardenability, grain refinement, and secondary hardening during tempering.

- D2 Steel:

- Mo: 0.70–1.00%

- V: 0.30–1.00%

- Forms hard vanadium carbides for superior wear resistance.

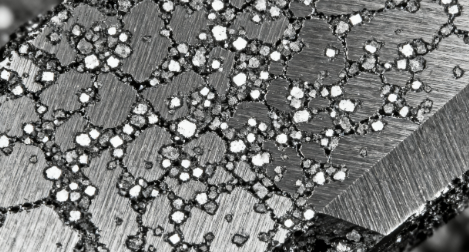

- Enhances cast structure and ledeburite morphology, boosting toughness.

Applications by Region:

- North America: D2 is preferred for high-volume cold extrusion dies and industrial shearing tools.

- India and Middle East: 8Cr13MoV is favored for general-purpose stamping and cutting tools, balancing cost and performance.

Summary of Alloy Contributions:

| Alloy Element | 8Cr13MoV Effect | D2 Steel Effect |

|---|---|---|

| Carbon (C) | Balanced hardness & toughness | Maximum wear resistance |

| Chromium (Cr) | Corrosion resistance & carbide formation | Deep hardening & carbide reinforcement |

| Molybdenum (Mo) | Secondary hardening | Hot strength & temper resistance |

| Vanadium (V) | Grain refinement | Hard vanadium carbides, superior toughness |

Optimized Takeaways

- D2 Steel is ideal for:

- Extreme wear resistance

- High-precision, long-life molds

- Applications in Europe, North America, and Japan

- 8Cr13MoV Steel is ideal for:

- Balanced hardness and toughness

- Moderate-impact tools

- Cost-effective production in China, India, and Southeast Asia

- Choosing the Right Steel requires considering:

- Carbon and carbide content

- Chromium for wear resistance

- Mo & V for toughness and secondary hardening

Beyond Hardness: Toughness, Ductility, and Impact Resistance

While hardness is often the primary concern for wear applications, toughness and ductility are equally important, especially for tools subjected to impact or varying stress levels. Here, the trade-offs between 8Cr13MoV and D2 steel become more apparent.

D2 Steel‘s Moderate Toughness: Balancing Strength with Performance

D2 steel is characterized by good wear resistance but only moderate toughness. Its high carbon and chromium content, forming a large volume of hard carbides, makes it very resistant to abrasive wear but inherently reduces its ability to absorb impact without fracturing. This means that while D2 steel excels in applications requiring high wear resistance, it might be more prone to chipping or cracking under severe impact loads if not properly managed through design and heat treatment. However, D2 steel’s strength and toughness can be significantly improved by adding rare earth elements, enhancing both wear resistance and impact toughness, which helps in extending the service life of tools.

8Cr13MoV’s Toughness Profile for High-Impact Applications

8Cr13MoV, with its lower carbon content compared to D2, generally offers a better balance of hardness and toughness. This characteristic makes 8Cr13MoV suitable for manufacturing cold work molds that experience significant impact forces. Its composition allows for a microstructure that can withstand these impacts more effectively than D2 in some scenarios, making it a viable option where moderate impact resistance is as crucial as wear resistance.

Deep Cryogenic Treatment and Its Impact on D2

To optimize D2 steel’s properties further, deep cryogenic treatment is sometimes employed. This process involves cooling the workpiece immediately after quenching to temperatures between -120 to -150°C for 3-4 hours, followed by tempering. This treatment helps to transform retained austenite into martensite and precipitate fine carbides, which can increase hardness by 1-3HRC and enhance dimensional stability during use. However, for complex molds, this method carries a risk of cracking and should be applied cautiously.

Chemical Composition and Its Impact on 8Cr13MoV vs D2 Steel Performance

To summarize the compositional differences and their direct impact on performance, the following table provides a clear comparison:

| Feature/Element | 8Cr13MoV Steel | D2 Steel |

| Carbon (C) | 0.70-0.80% (approx. 0.8%) | 1.40-1.60% (approx. 1.5%) |

| Chromium (Cr) | 13.0-14.5% (approx. 13%) | 11.5-13.0% (approx. 11.5-12.0%) |

| Molybdenum (Mo) | 0.10-0.30% | 0.70-1.00% |

| Vanadium (V) | 0.10-0.25% | 0.30-1.00% |

| Typical Hardness | Up to 60HRC after heat treatment | Up to 60HRC after heat treatment |

| Wear Resistance | High | Higher due to more carbides (C, Mo, V) |

| Toughness | Good for high-impact applications | Moderate, can be improved with rare earth |

| Corrosion Resistance | Good due to higher Cr content | Slightly insufficient; good after quenching/polishing |

| Key Advantage | Balanced hardness and toughness | Exceptional wear resistance, higher strength |

Mastering Heat Treatment for Optimal Performance

The full potential of both 8Cr13MoV and D2 steel is unlocked through precise heat treatment processes. For B2B buyers, understanding these processes is crucial for ensuring the final tool or mold meets the required specifications.

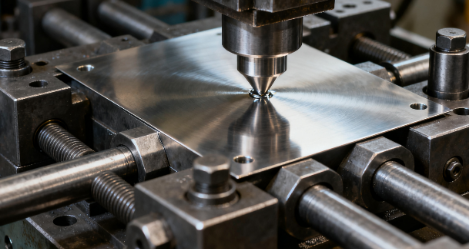

D2 Steel‘s Quenching & Tempering Secrets for Stability

D2 steel’s heat treatment involves several critical steps to achieve its desired properties. Quenching requires preheating to 650-750°C, followed by austenitizing at 990-1050°C (often 1000-1040°C), with sufficient holding time. Various quenching media can be used, including high-speed circulating gas, vacuum furnaces, salt baths, or warm oil for simpler molds. Immediately after cooling to 50-70°C, D2 steel must be tempered. Tempering is crucial, performed at least twice, with each cycle involving cooling to room temperature.

A minimum tempering temperature of 180°C and a holding time of at least 2 hours per cycle are recommended to achieve the desired hardness and stabilize the microstructure. These meticulous steps are vital for minimizing heat treatment deformation and ensuring the tool’s dimensional stability and performance.

Preventing Decarburization and Oxidation During Heat Treatment

For both 8Cr13MoV and D2 steel, preventing decarburization and oxidation during the quenching process is paramount. Decarburization, the loss of carbon from the surface, can reduce surface hardness and wear resistance, while oxidation can lead to surface pitting and dimensional inaccuracies. Utilizing protective atmospheres, vacuum furnaces, or salt baths during austenitizing and quenching can effectively mitigate these issues, ensuring the steel maintains its optimal properties. Stress relief annealing, performed after rough machining, also plays a critical role in reducing internal stresses and preventing deformation during subsequent heat treatment steps.

Practical Applications: When to Choose 8Cr13MoV vs D2 Steel

The choice between 8Cr13MoV and D2 steel ultimately depends on the specific requirements of the application, balancing factors like wear, impact, and cost.

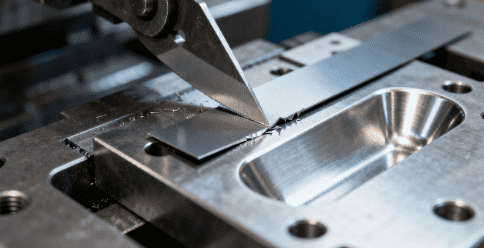

Cold Punching Dies & Shears: Common Ground for Both Steels

Both 8Cr13MoV and D2 steel are excellent candidates for manufacturing high-wear resistance, micro-deformation cold work molds. They are frequently used for silicon steel sheet punching dies, cold cutting shears, and trimming dies. For these general cold work applications, either steel can offer suitable performance, with the choice often coming down to the specific demands on tool life, the material being processed, and budget considerations.

D2 Steel for High-Precision and Extended-Life Molds

D2 steel truly shines in applications demanding exceptional wear resistance and extended mold life. Its superior strength and toughness (especially when enhanced by Mo, V, or rare earth additions) make it ideal for cold extrusion forming, drawing dies, and punching dies for stainless steel sheets and other high-hardness materials. For instance, D2 steel is specifically used for refrigerator compressor rear cover deep drawing dies.

It has been shown to increase the service life of tools like thread rolling dies and cold punch dies by 5-6 times compared to traditional Cr12MoV steel, highlighting its value for high-volume, long-life production. D2 steel is often preferred for complex tools that undergo severe abrasive wear, where the initial material cost is justified by significantly reduced downtime and replacement frequency.

Surface Treatment Options for Enhanced Durability

To further enhance the performance of both steels, especially D2, surface treatments like nitriding and nitrocarburizing can be applied. These treatments create a hardened surface layer that significantly boosts wear resistance, anti-erosion properties, and even corrosion resistance. For D2 steel, a recommended sequence includes rough machining, stress relief, semi-finishing, quenching and tempering, fine machining/EDM, and then nitriding to achieve optimal results. This multi-step process ensures that the base properties of the steel are maximized before adding a protective and performance-enhancing surface layer.

Conclusion

The choice between 8Cr13MoV vs D2 steel is a strategic one, driven by the nuanced demands of specific industrial applications. Both are formidable cold work tool steels capable of achieving 60HRC hardness, but their distinct chemistries—particularly in carbon, molybdenum, and vanadium content—dictate their ultimate performance profiles. 8Cr13MoV offers a balanced blend of hardness and good toughness, making it versatile for tools encountering moderate impact.

D2 steel, with its higher carbon, molybdenum, and vanadium, excels in extreme wear resistance and extended tool life, especially in high-precision, high-volume cold work applications, despite its more moderate toughness and slightly weaker inherent corrosion resistance. By understanding these fundamental differences and the impact of heat treatment and surface enhancement, B2B buyers can confidently select the optimal steel to unlock superior durability and efficiency for their projects.

FAQ

Q1: What is the primary difference in chemical composition between 8Cr13MoV vs D2 steel?

A1: The primary difference lies in their carbon, molybdenum, and vanadium content. D2 steel has significantly higher carbon (approx. 1.5% vs 0.8%), molybdenum (0.7-1.0% vs 0.1-0.3%), and vanadium (0.3-1.0% vs 0.1-0.25%) compared to 8Cr13MoV. These higher alloying elements in D2 contribute to its superior wear resistance.

Q2: Which steel is better for high-impact applications, 8Cr13MoV vs D2 steel?

A2: 8Cr13MoV generally offers a better balance of hardness and toughness, making it more suitable for cold work molds that experience significant impact forces. D2 steel has good wear resistance but only moderate toughness, making it more prone to chipping under severe impact if not properly treated or designed.

Q3: Can both 8Cr13MoV vs D2 steel achieve 60HRC hardness?

A3: Yes, both 8Cr13MoV and D2 steel are designed to achieve hardness levels of up to 60HRC after proper heat treatment.

Q4: How does D2 steel‘s corrosion resistance compare to 8Cr13MoV?

A4: D2 steel is considered a “semi-stainless steel” but its inherent corrosion resistance is noted as slightly insufficient or weaker. However, after quenching and polishing, its anti-rust capability is good. 8Cr13MoV has a higher chromium content (13-14.5%) which suggests good inherent corrosion resistance.

Q5: What are typical applications where D2 steel excels over 8Cr13MoV?

A5: D2 steel excels in applications requiring extreme wear resistance and long tool life, such as refrigerator compressor rear cover deep drawing dies, thread rolling dies, cold extrusion forming, drawing dies, and punching dies for stainless steel sheets and other high-hardness materials. It can increase tool life significantly compared to other steels.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀