Table of Contents

Introduction

For enthusiasts and professionals alike, understanding the nuances of blade materials is crucial when selecting a cutting tool. The core of any high-quality blade lies in its steel composition, a complex alloy engineered for specific performance characteristics. While the global demand for blade-specific alloys is too low to justify dedicated development costs, many premium blades are crafted from tool steels, originally designed for industrial cutting machines. These materials, marked by standards like AISI, are now central to the knife-making world, with terms like D2, M4, and O1 frequently appearing in discussions.

The journey of selecting the ideal blade material can be daunting, given the vast array of options available and the often-confusing mix of standards, names, and manufacturer-specific terminology. However, gaining a foundational understanding of different alloys allows for informed decisions, ensuring that the chosen tool perfectly matches its intended use. This blog post aims to demystify some of the leading high-performance blade materials, highlight their unique attributes, and answer common questions, guiding you towards unlocking the true value of your next cutting instrument. We will explore the characteristics that define a superior cutting alloy, delve into the specifics of some top-tier options, and examine the popular D2 steel.

What is the Best Knife Steel? Understanding Performance Factors

When discussing the “best” blade material, it’s essential to recognize that no single alloy excels in all aspects; rather, the optimal choice is always a compromise, a balance of various properties tailored to specific needs. The performance of any cutting alloy is determined by a delicate interplay of its elemental composition, which influences key characteristics like edge retention, corrosion resistance, wear resistance, toughness, and hardness.

Key Performance Factors for Knife Steel

Edge Retention

This refers to how long a blade can maintain its sharpness during use. High carbon content significantly contributes to an alloy’s hardness and, consequently, its ability to hold an edge. Elements like molybdenum, vanadium, and tungsten also play a role in enhancing edge retention.

Corrosion Resistance

The ability of the material to resist rust and other forms of chemical degradation. Chromium is the primary element responsible for corrosion resistance, forming a protective oxide layer on the surface. Adding more than 13% chromium to carbon steel turns it into stainless steel. Molybdenum, nickel, niobium, phosphorus, nitrogen, and copper also improve this property.

Wear Resistance

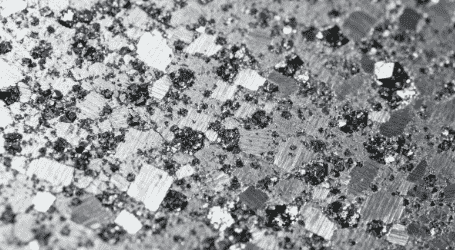

This property indicates how well the material resists abrasion and erosion during cutting. High carbon, vanadium, tungsten, and manganese content are crucial for excellent wear resistance. Powder metallurgy processes also contribute to superior wear resistance by creating a fine, uniform grain structure.

Toughness

A material’s ability to absorb energy and deform plastically without fracturing. While hardness often comes at the expense of toughness, a good balance is vital for a durable blade. Vanadium, niobium, and tungsten can enhance toughness, while specific heat treatment plays a significant role.

Hardness

Resistance to localized plastic deformation, typically measured on the Rockwell Hardness Scale (HRC). Carbon, chromium, cobalt, manganese, and boron are key elements for increasing hardness. Higher hardness generally correlates with better edge retention, though excessive hardness can lead to brittleness.

Many high-performance alloys are developed through advanced processes like Crucible Particle Metallurgy (CPM), which produces materials with uniform quality, fine crystallization, high wear resistance, superior toughness, and minimal heat treatment deformation. These advanced processes allow for the creation of blade materials that push the boundaries of performance.

Examples of High-Performance Knife Steel

CPM S110V

Regarded as a pinnacle in wear resistance and edge retention among mainstream blade materials, though its high hardness makes it challenging to sharpen.

Maxamet

A high-speed powder steel developed by Carpenter, known for extremely high edge retention and hardness while maintaining reasonable toughness.

M390

Produced by Bohler-Uddeholm using a third-generation powder alloy process, it’s celebrated for its balanced corrosion resistance, high hardness, and excellent wear resistance. It includes chromium, molybdenum, vanadium, and tungsten to enhance sharpness and edge retention.

Elmax

Another Bohler-Uddeholm product, this high-chromium-vanadium-molybdenum alloy powder steel offers carbon steel-like edge retention and wear resistance combined with good corrosion resistance, making it a well-balanced, excellent blade material.

CPM-M4

A high-speed tool steel, particularly in its modern powder metallurgy version (CPM REX M4 HC), known for exceptional toughness and wear resistance. It’s often chosen for large outdoor and survival tools due to its high resistance to mechanical stress.

These alloys exemplify the cutting edge of blade material technology, each offering a unique blend of properties to meet diverse user demands.

Sharpening Knife Steel: Understanding the Challenge

The process of sharpening a blade is intimately tied to the properties of the cutting alloy itself. While the query specifically mentions “sharpening a knife with a steel,” it’s important to clarify that “steel” in this context refers to the blade’s material, not a honing rod. The ease or difficulty of achieving and maintaining a sharp edge varies significantly among different blade materials, largely depending on their hardness, wear resistance, and the types of carbides present.

Blade materials with exceptionally high wear resistance, such as CPM S110V and Maxamet, which score 10 out of 10 for wear resistance, are notoriously difficult to sharpen. While they retain their edge for an incredibly long time, resharpening them requires significant skill, specialized abrasives, and considerable patience. Blade smiths have been known to express frustration with these “wear-resistant to the point of making blade smiths curse” materials, even as users love their edge retention.

Conversely, softer blade materials with lower wear resistance, like 1095 carbon steel, are much easier to sharpen. However, this ease of sharpening often comes at the cost of reduced edge retention, meaning the blade will need to be sharpened more frequently. Similarly, low-end blade materials like 420J, which have low carbon content and are relatively soft, are easy to grind but also have poor edge retention and wear resistance.

D2 steel, for example, is noted for requiring a higher level of skill during grinding. This is due to its good edge retention and wear resistance, which make it more challenging than softer materials but generally more manageable than ultra-hard powder steels. The presence of hard carbides formed by elements like vanadium contributes to wear resistance, but these same carbides can make the grinding process more arduous.

The choice of sharpening method and abrasive should always be matched to the specific blade material. For softer, easier-to-sharpen alloys, basic sharpening stones or ceramic rods might suffice. However, for harder, more wear-resistant materials, diamond-based abrasives or advanced sharpening systems are often necessary to effectively remove material and re-establish a keen edge. Ultimately, understanding the inherent characteristics of your blade’s material is key to successful sharpening.

Is D2 Steel Good for Knife? A Detailed Look

D2 steel stands as a prominent example of a tool steel that has successfully transitioned into the knife-making world, earning a reputation for its excellent balance of properties and value. Originating from the metalworking industry, where it was primarily used for making steel cutting dies, D2 is quite literally a “steel for cutting steel,” speaking volumes about its inherent toughness and cutting capabilities.

Advantages of D2 Knife Steel

- Exceptional Edge Retention: D2 offers superior edge retention compared to many other materials, such as 154CM, making it capable of handling demanding cutting tasks. This is attributed to its chemical composition, including high carbon (1.4-1.6%) and chromium (11-13%).

- Overall Excellent Performance: It provides an optimal combination of performance and cost-effectiveness. While not the absolute top in hardness, toughness, or cutting stability individually, D2 possesses no significant weaknesses, making it a well-rounded performer. It’s often considered an upgrade from basic, lower-grade stainless steels and is commonly found in entry-to-mid-range production blades.

- High Hardness and Toughness: D2 can be hardened to an impressive 60-61 HRC without becoming brittle. Its robust construction allows it to withstand heavy use, and it is frequently favored for outdoor and survival blades.

- Widespread Use and Trust: Many custom blade makers and top production companies like CRKT, Kershaw, SOG, A.G. Russell Knives, Ontario, and KA-BAR extensively use D2 in their product lines. Its long-standing presence and consistent performance have cemented its status as a reliable choice.

- “Semi-Stainless” Properties: With a chromium content of approximately 13%, D2 is considered a “semi-stainless” material, just below the threshold for full stainless classification. This means it offers a degree of corrosion resistance, although it does require more care than true stainless steels to prevent rust.

Disadvantages of D2 Knife Steel

- Corrosion Susceptibility: As a “semi-stainless” material, D2 is not entirely rust-proof and requires more diligent care to prevent corrosion compared to fully stainless alloys.

- Sharpening Difficulty: Its excellent edge retention and wear resistance mean that D2 requires a higher skill level for sharpening compared to softer steels.

- Quality Variability: Due to the numerous manufacturers supplying D2, there can be significant differences in quality, which can sometimes lead to inconsistent performance or perceived issues like unsatisfactory cutting stability or chipping. This highlights the importance of the manufacturer’s heat treatment process, which can profoundly impact the final properties of any blade material.

Despite these minor drawbacks, the performance advantages of D2 generally outweigh its disadvantages. Its balanced properties make it an excellent choice for a wide array of applications, from everyday carry (EDC) folding blades to robust outdoor tools.

Comparative Table of Popular Knife Steels

To further illustrate the diverse landscape of blade materials, here is a comparative table of some popular options, scored (out of 10) for their key performance attributes as per available sources. It’s important to remember that these scores are relative and represent a general consensus.

| Steel Name | Edge Retention | Corrosion Resistance | Wear Resistance | Key Characteristics & Notes |

| CPM S110V | 10 | 6 | 10 | Extreme wear resistance and edge retention, challenging to sharpen. Powder metallurgy steel from Crucible Industries. |

| Maxamet | 10 | 6 | 10 | High-speed powder steel with exceptional edge retention and hardness. From Carpenter. |

| CPM S90V | 9 | 5 | 10 | Excellent wear resistance and edge retention, slightly less than S110V. High carbon and vanadium content. |

| M390 | 9 | 7 | 9 | “Super steel” with excellent corrosion resistance, high hardness, and wear resistance. Third-gen powder alloy from Bohler-Uddeholm. |

| Elmax | 8 | 5 | 8 | Balanced high-chromium-vanadium-molybdenum alloy powder steel. Good edge retention, wear resistance, and corrosion resistance. |

| CPM-M4 | 9 | 2 | 9 | High-speed tool steel, extremely tough and wear-resistant, especially in powder metallurgy form. Low chromium means poor corrosion resistance, often coated. |

| D2 | 8 | 2 | 8 | Tool steel, “semi-stainless.” Good edge retention and wear resistance, requires care for corrosion. Widely used due to balanced performance. |

| CPM S30V | 7 | 7 | 6 | Excellent balance of edge retention, rust resistance, hardness, and toughness. Contains vanadium carbide. From Crucible Industries. |

| 154CM | 6 | 6 | 6 | Harder steel, often seen as 440C with added molybdenum for improved edge retention, good corrosion resistance, and toughness. |

| VG-10 | 6 | 7 | 5 | Japanese steel, similar to 154CM but with higher chromium for improved corrosion resistance and added vanadium for hardness and sharpness. |

| 440C | 4 | 4 | 5 | Representative US stainless steel, good wear resistance and toughness but moderate corrosion resistance. Good value for money. |

| 1095 | 3 | 2 | 3 | Widely used carbon steel for blades. Poor corrosion resistance and edge retention but easy to sharpen and inexpensive. Often coated. |

Note: The scores are approximations based on source information. Individual performance can vary based on specific manufacturing and heat treatment processes.

Conclusion

The world of blade materials is rich and varied, offering a spectrum of options designed to meet virtually any cutting requirement. As we’ve explored, there is no single “best” knife steel; rather, the most suitable choice depends on a careful consideration of desired performance characteristics, intended use, and maintenance commitment. From the ultra-hard, wear-resistant powder metallurgy alloys like CPM S110V and Maxamet to the balanced versatility of D2, each material presents a unique set of compromises and advantages.

High-performance blade materials, often originating as industrial tool steels, bring exceptional qualities like superior edge retention, formidable wear resistance, and impressive hardness to everyday tools. However, these advanced properties often come with trade-offs, such as increased sharpening difficulty or specific corrosion care requirements. The enduring popularity of D2 steel, for example, lies in its harmonious blend of good edge retention, wear resistance, and relative affordability, making it a reliable workhorse for a wide range of applications despite its non-stainless nature.

Ultimately, an informed decision about blade material goes beyond merely knowing the alloy’s name. It involves understanding how elements like carbon, chromium, molybdenum, and vanadium contribute to properties such as edge retention, corrosion resistance, and toughness. Crucially, the quality of a blade is not solely determined by its alloy composition but significantly by the excellence of its heat treatment process. Even the most advanced cutting material can be rendered inferior by a small error in heat treatment. By considering these factors, you can confidently select a blade that will perform optimally for your specific tasks, ensuring longevity and satisfaction.

FAQ

Q1: What are the primary factors to consider when selecting a knife steel?

A1: When choosing a blade material, the main factors to consider are edge retention (how long it stays sharp), corrosion resistance (resistance to rust), wear resistance (resistance to abrasion), toughness (resistance to chipping/breaking), and hardness (resistance to deformation). Different blade materials offer varying balances of these properties.

Q2: Is “stainless” knife steel truly rust-proof?

A2: No blade material is entirely rust-proof, but “stainless” varieties offer significantly improved corrosion resistance. Materials are generally classified as stainless steel when they contain 13% or more chromium, which forms a protective oxide layer. However, even stainless alloys can stain or rust under certain conditions or prolonged exposure to corrosive elements. D2, with about 13% chromium, is considered “semi-stainless” and requires more care than true stainless options.

Q3: What does HRC mean in the context of knife steel?

A3: HRC stands for Rockwell Hardness, specifically the “C” scale. It’s a standard measurement for the hardness of blade materials, indicating resistance to permanent indentation. A higher HRC generally means a harder material, which often correlates with better edge retention. For example, D2 can be hardened to over 60-61 HRC without becoming brittle.

Q4: Why are some knife steels significantly more expensive than others?

A4: The cost of blade material can vary based on several factors. Advanced production methods, such as powder metallurgy processes (e.g., Crucible Particle Metallurgy), are more complex and costly. The inclusion of expensive or rare alloying elements like vanadium, molybdenum, or cobalt also increases material cost. Additionally, the balance of superior performance properties often drives up the price for high-end blade materials.

Q5: How important is heat treatment for the performance of a knife steel?

A5: Heat treatment is critically important, arguably as significant as the material’s composition itself. A small error in the heating and quenching processes during heat treatment can degrade the performance of any blade material, making even a high-quality alloy inferior or completely unusable. Proper heat treatment optimizes the material’s crystalline structure, bringing out its designed hardness, toughness, and edge retention capabilities.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀