Table of Contents

Introduction

In the vast and intricate world of mechanical design and industrial manufacturing, selecting the right material is paramount to the success and longevity of any project. Among the myriad of choices, tool steel stands out as an indispensable category, revered for its exceptional properties and versatility. It is a specialized type of steel, specifically engineered to withstand demanding operational conditions, making it the preferred choice for manufacturing a wide array of tools, dies, and molds. Shandong Qilu Industrial Co.,Ltd. (Qilu), established in 1985, has positioned itself as a professional solution provider for tool steel and mold steel, ensuring that these critical materials are carefully forged to achieve superior durability, cutting performance, and thermal treatment stability.

This guide aims to provide a comprehensive overview of tool steel, exploring its classifications, chemical compositions, characteristics, and diverse applications, empowering mechanical designers and enthusiasts with the knowledge to make informed decisions. Understanding tool steel is not just about knowing material specifications; it’s about unlocking the potential for enhanced precision, efficiency, and resilience in manufacturing.

Understanding Tool Steel Classification

Tool steel, a subset of special steel, is broadly classified based on its intended use and the specific environmental conditions it is designed to operate under. The diverse applications demand a variety of mechanical and chemical properties, leading to distinct categories of tool steel. In a broader context, steel itself can be classified in numerous ways, including by quality (ordinary, quality, high-quality steel), chemical composition (carbon steel, alloy steel), forming method (forged, cast, hot-rolled, cold-drawn), metallographic structure, and purpose.

However, for tool steel specifically, a more practical classification often revolves around the temperature and stress conditions of its working environment. This categorization includes cold work tool steel, hot work tool steel, plastic mould steel, high-speed tool steel, and impact resistant tool steel.

Cold Work Tool Steel: Characteristics and Applications

Cold work tool steel is engineered for applications where tools operate at ambient temperatures, enduring immense pressure, severe abrasion, and bending stresses. The primary requirements for this category of tool steel include high hardness, typically above HRC 58, excellent wear resistance, high compressive strength, and adequate toughness.

Common grades of cold work tool steel include:

• D2 (Cr12Mo1V1 / SKD11): This high-carbon, high-chromium tool steel, known by the Japanese JIS standard SKD11, achieves hardness levels of 62 HRC and above after quenching. It offers good toughness, impact resistance, fatigue resistance, and favorable wear and corrosion resistance. Due to its high hardness and alloy content, processing D2 tool steel can be challenging, requiring specific tools and processes.

• D3 (Cr12 / SKD1): A domestic high-carbon, high-chromium cold work tool steel, considered a simplified version of SKD11. It reaches a hardness of HRC 58-62 after quenching and exhibits good wear resistance. However, D3 tool steel has relatively lower toughness and weaker impact resistance compared to D2, while being more cost-effective and slightly less corrosion-resistant than SKD11. Its processing is difficult, leading to rapid tool wear during cutting and lower efficiency, demanding high-quality processing equipment and tools.

• A2 (1.2363): Notable for its improved surface finish and high wear resistance, making it suitable for precision tools.

• O1 (1.2510): Demonstrates excellent performance in high-speed cutting applications, offering numerous benefits.

• D6 (1.2436).

In non-standard mechanical design, cold work tool steel is often used for wear-resistant components like guide slots, parts in relative motion (e.g., Cr12), and pressing heads (e.g., SKD11).

Hot Work Tool Steel: Characteristics and Applications

Hot work tool steel is designed for tools that process heated metals at high temperatures, often ranging from 300-600°C or even higher, while repeatedly enduring rapid heating and cooling cycles. The critical demands for this type of tool steel include maintaining high strength and hardness at elevated temperatures (red hardness), superior thermal fatigue resistance to prevent cracking, good thermal conductivity, and adequate toughness.

Common types of hot work tool steel include:

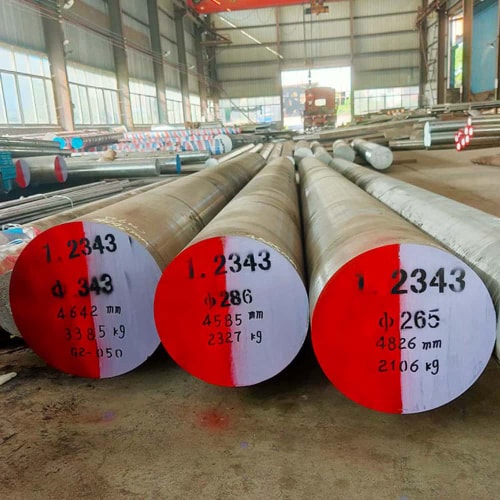

• Chromium series (e.g., H10-H19, such as H13/1.2344, H11/1.2343, H10/1.2365): These are the most widely used, offering excellent comprehensive performance and superior thermal fatigue resistance. They are the preferred choice for aluminum and magnesium alloy die-casting molds. H11 and H13 are identified as key choices for hot work molds.

• Tungsten series (e.g., H20-H26, such as H21): These exhibit better high-temperature strength and erosion resistance but possess lower toughness. They are frequently used for copper alloy die-casting and hot extrusion molds.

• Molybdenum series: The properties of these tool steel types fall between those of the chromium and tungsten series.

Hot work tool steel finds application in die-casting molds, hot forging dies, hot extrusion dies, and hot shear blades. In non-standard mechanical design, it is commonly utilized for hot cutting blades.

Plastic Mould Steel: Characteristics and Applications

Plastic mould steel operates at relatively lower temperatures, typically below 300°C, encountering pressure and abrasion from molten plastic, and potentially corrosive gases. The essential requirements for plastic mould steel include excellent polishability (achieving mirror-like finishes), good etchability for intricate textures, certain levels of wear and corrosion resistance, and superior dimensional stability.

Common types of plastic mould steel include:

• Pre-hardened type (e.g., P20/1.2311, 718/1.2738): These tool steels are supplied pre-heat-treated to HRC 30-36, allowing for direct machining into molds, thus avoiding deformation from additional heat treatment. They are suitable for medium to large general plastic molds.

• Precipitation hardening type (e.g., NAK80/1.2312): Hardened through age hardening, these tool steels exhibit minimal deformation and excellent mirror polishability. They are used for transparent part molds requiring high surface finishes.

• Corrosion-resistant type (e.g., 420, S136/1.2083): These are martensitic stainless tool steels that resist corrosion from gases like PVC. They are used for molds processing transparent plastics and corrosive plastics. S136/NAK80 steel is highlighted for optimizing molds with enhanced precision and durability.

Applications for plastic mould steel include injection molds for television casings, automotive components, bottle caps, and transparent lenses. S136 tool steel is specifically used in non-standard mechanical designs for corrosion-resistant applications, eliminating the need for additional surface treatments.

High Speed Tool Steel: Characteristics and Applications

High speed tool steel is specifically designed for manufacturing cutting tools that operate at high speeds, where friction between the cutting edge and chips generates extremely high temperatures, often between 500-600°C. Also known as “white steel,” the critical demands for high speed tool steel are exceptionally high red hardness (the ability to maintain high hardness at elevated temperatures), extremely high wear resistance, and adequate toughness.

Common types of high speed tool steel include:

• General-purpose type (e.g., W6Mo5Cr4V2, equivalent to Japan’s SKH-9 and USA’s M2): This is the most common type, offering high cost-effectiveness and good overall performance. M2 tool steel is among the hot products.

• Tungsten series (e.g., T1): These offer slightly better wear resistance but have lower toughness and are more expensive.

• High-cobalt super-hard type (e.g., M35, M42): With added cobalt, these tool steels provide even higher red hardness and overall hardness, making them suitable for machining high-strength materials. M3, M4, M7, M35, M42 are also listed as hot products.

High speed tool steel is widely used for drills, milling cutters, turning tools, gear cutting tools, and saw blades. In non-standard mechanical design, it is primarily employed for cutting tools, such as the shears in mask manufacturing machines.

Impact Resistant Tool Steel: Characteristics and Applications

Impact resistant tool steel is formulated to endure high-energy, intermittent, and severe impacts and vibrations. The foremost requirements for this tool steel category are extremely high toughness and impact resistance, while its hardness is comparatively lower, typically ranging from HRC 50-55.

Common grades of impact resistant tool steel include 4CrW2Si or 5CrW2Si.

This tool steel is primarily used for manufacturing tools that bear impact loads, such as punches for blanking dies, shear blades for cutting machines, and tools for crushing machines. It can also be utilized for cold work dies that require a certain degree of toughness, like cold heading dies and bending dies. Furthermore, in mechanical manufacturing, impact resistant tool steel can be used to produce wear-resistant components subjected to impact.

Decoding Tool Steel Chemical Composition and Designation

Understanding the designation system for tool steel is crucial for mechanical designers to accurately identify and select materials. In China, steel grades are designated using a combination of Chinese Pinyin letters, chemical element symbols, and Arabic numerals, following the national standard GB221-79.

Here’s how tool steel and related special steels are generally designated:

• Chemical Elements: International chemical symbols like Si, Mn, Cr are used. Mixed rare earth elements are denoted by “RE” or “Xt”.

• Product Name/Purpose: Often indicated by Pinyin abbreviations.

• Content of Main Chemical Elements: Represented by Arabic numerals as percentages.

Specifically for different types of tool steel:

• Carbon tool steel:

◦ The steel grade is prefixed with “T” to distinguish it from other steel types.

◦ The number in the grade indicates the average carbon content in thousandths of a percent. For example, “T8” signifies an average carbon content of 0.8%.

◦ If manganese content is higher, “Mn” is appended at the end of the grade, e.g., “T8Mn”.

◦ High-grade premium carbon tool steel, with lower phosphorus and sulfur content than general premium carbon tool steel, has an “A” appended at the end, e.g., “T8MnA”.

• Alloy tool steel:

◦ If the average carbon content is ≥1.0%, it is not explicitly marked. If it’s <1.0%, it is expressed in thousandths of a percent, e.g., Cr12, 9SiCr.

◦ The representation of alloy element content is generally similar to alloy structural steel. However, for alloy tool steels with lower chromium content, the chromium content is expressed in thousandths of a percent, with a “0” added before the number to differentiate it from percentages, e.g., Cr06.

• High speed tool steel:

◦ The carbon content is generally not marked in the grade.

◦ Only the average percentage of each alloy element is indicated. For example, a tungsten series high speed tool steel might be designated “W18Cr4V”.

◦ If the grade is prefixed with “C,” it means its carbon content is higher than the general grade without “C”.

These systematic designations allow for precise communication and selection of the appropriate tool steel for specific industrial demands, ensuring that the chemical composition aligns with the required mechanical properties for the application.

Here is a summary table of different tool steel types:

| Tool Steel Type | Primary Working Conditions | Key Characteristics | Common Grades (Examples) | Primary Applications |

| Cold Work Tool Steel | Ambient temperature, high pressure, severe abrasion, bending | High hardness (HRC > 58), high wear resistance, high compressive strength, good toughness | D2 (SKD11), D3 (Cr12), A2, O1, D6 | Guide slots, pressing heads, punches, blanking dies |

| Hot Work Tool Steel | High temperatures (300-600°C+), rapid heating/cooling | High red hardness, excellent thermal fatigue resistance, good thermal conductivity, toughness | H13, H11, H10, H21 | Die-casting molds, hot forging dies, hot extrusion dies, hot shear blades |

| Plastic Mould Steel | Low-medium temperatures (<300°C), plastic melt pressure, abrasion, potential corrosion | Excellent polishability, good etchability, wear resistance, corrosion resistance, dimensional stability | P20, 718, NAK80, S136 (420) | Injection molds for plastic products (e.g., automotive parts, transparent lenses) |

| High Speed Tool Steel | High-speed cutting, tool tip temperatures (500-600°C) | Extremely high red hardness, extremely high wear resistance, good toughness | M2 (SKH-9), M3, M4, M7, M35, M42 | Drills, milling cutters, turning tools, gear cutting tools, saw blades |

| Impact Resistant Tool Steel | High-energy, intermittent, severe impact and vibration | Extremely high toughness, high impact resistance, moderate hardness (HRC 50-55) | 4CrW2Si, 5CrW2Si | Chisels, punches, riveting tools, rock drill bits, shear blades, cold heading dies |

Key Properties and Advantages of Tool Steel

Tool steel differentiates itself from ordinary steel through a set of unique properties tailored for demanding applications. These materials are designed with enhanced performance characteristics that are crucial for the tools and components they form. The primary advantages include:

• Higher Strength and Toughness: Unlike general steels, tool steel is engineered to withstand greater forces and impacts without fracturing, offering both robust strength and resilience. Carefully forged tool steel ensures excellent durability.

• Special Physical and Chemical Properties: These can include resistance to high temperatures, specific electrical properties, or unique magnetic behaviors, depending on the alloy composition.

• Biocompatibility: While not universally applicable, some specialized tool steels might exhibit biocompatible properties for medical device applications. However, the sources don’t elaborate on this for general tool steel.

• Excellent Processability: This refers to the ease with which the tool steel can be machined, cut, formed, and heat-treated to achieve the desired shape and final properties.

In addition to these overarching advantages, specific types of tool steel possess specialized properties to meet their application requirements:

• High Hardness and Wear Resistance: Essential for resisting abrasive wear and plastic deformation. A2 tool steel, for example, offers high wear resistance.

• Red Hardness: The ability to maintain high hardness even at elevated temperatures, which is critical for high-speed cutting and hot work applications.

• Resistance to Thermal Fatigue: The capacity to withstand repeated cycles of rapid heating and cooling without developing cracks, crucial for hot work molds.

• Good Thermal Conductivity: Aids in dissipating heat efficiently, reducing thermal stress in tools.

• Excellent Polishability and Etchability: Especially vital for plastic mould steel to achieve mirror finishes or intricate textures.

• Corrosion Resistance: Important for tools exposed to corrosive environments, such as certain plastic moulding processes. S136 tool steel, for instance, is chosen for its corrosion resistance.

These combined properties make tool steel an essential material category, enabling the creation of durable, high-performing tools that are fundamental to modern manufacturing processes.

Achieving Precision with Tool Steel and Processing Services

The intrinsic qualities of tool steel are only fully realized when coupled with expert processing and manufacturing techniques. Qilu, with over 30 years of experience in the steel industry, emphasizes the importance of comprehensive steel processing services to enhance efficiency. These services are critical for transforming raw tool steel into components that meet stringent industrial requirements.

Key processing services offered include:

• Cutting and Machining: Precision cutting and mechanical machining are foundational steps in preparing tool steel for its intended use. This ensures the initial dimensions are accurate and ready for further fabrication.

• Heating and Forging: Forging is a crucial process where tool steel is shaped under heat and pressure. It refines the grain structure of the steel, significantly improving its mechanical properties like toughness and strength. Qilu’s tool steel and die steel are carefully forged to ensure excellent durability and cutting performance.

• Heat Treatment: This involves controlled heating and cooling cycles to alter the microstructure of the tool steel, thereby achieving desired properties such as hardness, strength, and wear resistance. Heat treatment stability is a key feature of quality tool steel.

Beyond standard processing, professional customization services are also vital. Qilu offers a variety of process processing and steel type customization services to meet diverse product needs and assists customers in research and development, allowing for tailor-made solutions for specific applications. The availability of an ample stock of common tool steel products ensures fast delivery times, accommodating customers’ varied requirements and enabling convenient use. Coupled with advanced production equipment and a professional technical team, these services ensure the provision of superior quality tool steel products and solutions.

Qilu’s team of experts, with extensive experience and deep understanding of various tool steels, can guide customers in selecting the best solution based on intended use, production process, required strength, and budget. This holistic approach, from material supply to specialized processing, is crucial for achieving the precision and quality expected in modern mechanical design.

Conclusion

Tool steel is undoubtedly a cornerstone of modern industrial and mechanical design, offering an unparalleled combination of strength, durability, and specialized performance characteristics tailored for a vast array of demanding applications. From the resilient cold work tool steel that shapes components at room temperature, to the robust hot work tool steel that withstands extreme heat, the precision-focused plastic mould steel, the incredibly hard high speed tool steel for cutting, and the shock-absorbing impact resistant tool steel, each category serves a critical function in the manufacturing ecosystem.

Understanding the nuances of tool steel, including its classification, the specific chemical compositions denoted by its designation, and the unique properties it offers, is not merely academic; it is a practical necessity for designers and engineers. The careful selection and precise processing of tool steel directly translate into the reliability, efficiency, and longevity of the final product. As industries continue to evolve, the demand for high-performance materials like tool steel will only grow, underscoring the importance of informed choices and leveraging expert knowledge. By grasping the wisdom encapsulated in this guide, professionals can confidently navigate the complexities of tool steel selection, contributing to innovation and excellence in mechanical design.

FAQ

Q1: What are the main types of tool steel based on working conditions?

A1: Based on working conditions, the main types of tool steel are cold work tool steel, hot work tool steel, plastic mould steel, high speed tool steel, and impact resistant tool steel. Each type is designed for specific temperature ranges and stress levels encountered during operation.

Q2: Why is “red hardness” a crucial property for some tool steel applications?

A2: Red hardness refers to the ability of tool steel to maintain its high hardness and strength at elevated temperatures. This property is crucial for applications like high-speed cutting tools, where friction generates significant heat, and for hot work molds that operate at extreme temperatures, preventing the tool from softening and losing its cutting edge or structural integrity.

Q3: How are tool steel grades typically designated in terms of carbon content?

A3: For carbon tool steel, the grade is prefixed with “T,” and the number indicates the average carbon content in thousandths of a percent (e.g., T8 for 0.8% carbon). For alloy tool steel with less than 1.0% carbon, it’s also expressed in thousandths (e.g., 9SiCr), but for 1.0% or more, carbon content is not explicitly marked. For high speed tool steel, carbon content is generally not marked in the grade, with focus on alloy elements.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀