Table of Contents

Introduction

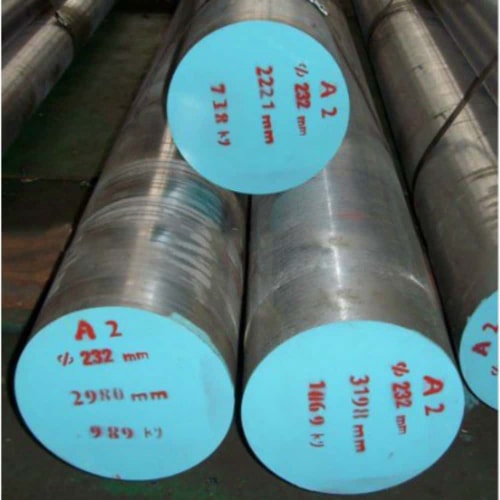

A2 Tool Steel is a widely used type of air-hardening tool steel known for its excellent balance of wear resistance, toughness, and dimensional stability after heat treatment. As a member of the cold work tool steel family, A2 is particularly popular in industrial applications where tooling must maintain its shape and hardness under demanding conditions. Unlike water or oil-hardening steels, A2 Tool Steel hardens when exposed to air, which significantly reduces the risk of distortion and cracking during quenching. This makes it a preferred choice for a variety of tool and die-making applications.

The chemical composition of A2 Tool Steel typically includes around 1% carbon for hardness and strength, 5% chromium for wear resistance and hardenability, and small amounts of molybdenum and vanadium to enhance toughness and refine grain structure. These elements work together to give A2 its unique properties that set it apart from other tool steels like D2 or O1.

Chemical Composition and Material Properties

Understanding the properties of A2 Tool Steel begins with its composition. Below is a detailed table showing the typical chemical makeup and key physical characteristics:

| Element | Percentage (%) | Role in A2 Tool Steel |

|---|---|---|

| Carbon (C) | 0.95–1.05 | Increases hardness and wear resistance |

| Chromium (Cr) | 4.75–5.50 | Enhances hardenability and wear resistance |

| Molybdenum (Mo) | 0.90–1.40 | Improves toughness and hot hardness |

| Vanadium (V) | 0.15–0.50 | Refines grain structure and increases wear resistance |

| Manganese (Mn) | 0.10–0.50 | Aids in hardenability and deoxidation |

| Silicon (Si) | 0.10–0.50 | Strengthens ferrite and improves oxidation resistance |

| Iron (Fe) | Balance | Base material |

In addition to its chemical composition, A2 Tool Steel exhibits the following mechanical properties:

- Hardness: Typically ranges from 57 to 62 HRC after heat treatment

- Tensile Strength: Around 1,800 MPa (260 ksi)

- Yield Strength: Approximately 1,600 MPa (230 ksi)

- Elongation at Break: Around 10–15%

- Impact Toughness: Moderate to high, depending on heat treatment

These properties make A2 an ideal candidate for applications requiring a balance between wear resistance and impact resistance.

Heat Treatment and Machinability of A2 Steel

One of the standout features of A2 Tool Steel is its air-hardening characteristic, which simplifies the heat treatment process compared to oil or water-quenched steels. The typical heat treatment steps include:

- Preheating: To minimize distortion and cracking, A2 is usually preheated to around 1,400°F (760°C).

- Austenitizing: Next, the steel is heated to between 1,750°F and 1,850°F (950°C–1,010°C), depending on the desired hardness and application.

- Quenching: A2 is then cooled in still air, which contributes to its dimensional stability.

- Tempering: After quenching, the steel is tempered at 300°F to 1,000°F (150°C–540°C) to reduce brittleness and achieve the desired hardness.

Machinability of A2 Tool Steel is generally good in the annealed condition. However, once hardened, it becomes more challenging to machine and is typically ground or EDM (Electrical Discharge Machined). It is often annealed before machining to a hardness of about 210–250 HBW, making it easier to shape before final hardening.

Surface treatments such as nitriding or PVD coatings can further enhance the wear resistance of A2 tools, extending their service life in high-stress environments.

To learn more, please click:

- Why Heat Treating A2 Tool Steel Enhances Durability

- Why A2 Tool Steel Heat Treating Matters for Longevity

- Understanding the Importance of A2 Tool Steel Heat Treatment

Applications of A2 Tool Steel in Manufacturing and Industry

A2 Tool Steel is extensively used across a wide range of industrial sectors due to its versatility and performance characteristics. Some of the most common applications include:

- Punches and Dies: A2 is widely used for making punches, blanking dies, and forming dies due to its ability to retain sharp edges and resist wear.

- Gauges and Measuring Tools: Its dimensional stability makes it ideal for the production of precision gauges and measuring instruments.

- Cold Forming Tools: In cold heading, cold extrusion, and thread rolling operations, A2 provides the necessary wear resistance and toughness.

- Plastic Mold Components: It is often used in mold cores and cavities, especially where moderate wear resistance and polishability are required.

- Industrial Knives and Trimming Tools: A2 is used for shearing blades, slitting knives, and trimming tools in the paper, textile, and metalworking industries.

Beyond these, A2 Tool Steel is also employed in the production of fixtures, jigs, and gauges in the automotive and aerospace sectors. Its combination of wear resistance and ease of heat treatment makes it a go-to material for toolmakers seeking a balance between performance and cost.

To learn more about the application of a2 tool steel in various industries, please click below to browse:

Global Market Demand and Regional Trends

The demand for A2 Tool Steel varies across the globe, influenced by industrial growth, technological advancements, and manufacturing specialization.

North America: The United States and Canada have a strong demand for A2 Tool Steel, particularly in the automotive, aerospace, and precision tool manufacturing sectors. With a focus on high-quality tooling, North American manufacturers often specify A2 for its reliability and consistency.

Europe: Germany, France, and Italy are major consumers of A2 Tool Steel in Europe. These countries are known for their high-precision engineering industries, where A2 is favored for its dimensional stability and ease of heat treatment. The European market also shows a growing interest in sustainable manufacturing practices, leading to increased recycling and reuse of tool steels.

Asia-Pacific: China, India, and Japan are among the largest consumers of A2 Tool Steel. The rapid expansion of manufacturing industries in these regions, especially in electronics, automotive, and consumer goods, has significantly boosted demand. In Japan, A2 is commonly used in the production of high-precision molds and dies for electronics and automotive components.

Middle East and Africa: While the market is smaller compared to other regions, there is growing interest in tool steel applications in infrastructure and industrial development, particularly in Saudi Arabia, UAE, and South Africa.

South America: Brazil and Mexico are the primary markets in Latin America, with A2 Tool Steel being used in automotive and general engineering sectors. Local production and import trends show steady growth, especially in tool and die shops.

The global market is also being shaped by the increasing adoption of high-performance tooling solutions in emerging economies, as well as advancements in powder metallurgy and surface treatment technologies that enhance the properties of traditional steels like A2.

To learn more, please click:

- 5 Game-Changing Trends in Steel for Construction

- 5 Powerful Tool Steel Material Uses in Automotive

- Top 9 Versatile Grades of Steel Today

FAQ

Here are some commonly asked questions about A2 Tool Steel:

1. Is A2 Tool Steel stainless?

No, A2 Tool Steel is not stainless. While it contains chromium, the amount is not sufficient to provide full corrosion resistance. However, it does offer better corrosion resistance than carbon steels.

2. What is the hardness of A2 Tool Steel after heat treatment?

A2 typically achieves a hardness range of 57–62 HRC after proper heat treatment, depending on the tempering temperature.

3. Can A2 Tool Steel be welded?

Yes, A2 can be welded, but it requires preheating and post-weld heat treatment to prevent cracking and maintain the material’s properties.

4. How does A2 compare to D2 Tool Steel?

A2 offers better toughness and is easier to machine than D2, but D2 has higher wear resistance due to its higher chromium and carbon content.

5. What are the main advantages of using A2 Tool Steel?

Its advantages include excellent dimensional stability, good wear resistance, moderate toughness, and ease of heat treatment.

Conclusion

A2 Tool Steel remains a cornerstone in the tool and die industry due to its balanced properties and versatile applications. Whether used in manufacturing, mold-making, or high-precision engineering, A2 provides a reliable combination of wear resistance, toughness, and ease of fabrication. Its air-hardening characteristic makes it particularly appealing for applications where distortion control is critical.

As global manufacturing continues to evolve with a focus on efficiency, precision, and sustainability, A2 Tool Steel is likely to maintain its relevance. Its adaptability to modern processing techniques and compatibility with surface treatments ensure that it will continue to meet the demands of tomorrow’s industries. For engineers, toolmakers, and manufacturers alike, understanding the capabilities and applications of A2 Tool Steel is essential for optimizing performance and cost-effectiveness in tooling solutions.

Whether you’re selecting material for a new die, designing a mold, or building precision instruments, A2 Tool Steel offers a proven and reliable choice backed by decades of industrial use and refinement.

To learn more, please click:

- Tool Steel A2: A Comprehensive Buyer’s Guide

- Tool Steel A2: A Comprehensive Guide

- Essential Guide to A2 Tool Steel Round Bar

- Understanding A2 Tool Steel: Properties, Applications, and Benefits

A2 (1.2363) Cold Work Tool Steel

A2 Steel (1.2363) is a high-quality, air-hardening, cold-work tool steel known for its combination of good wear resistance, high toughness, and excellent dimensional stability. It is widely used in the production of tools that require a balance between hardness and durability, making it ideal for medium to heavy-duty cold-working applications.

✨ Let’s Stay Connected!

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀