Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

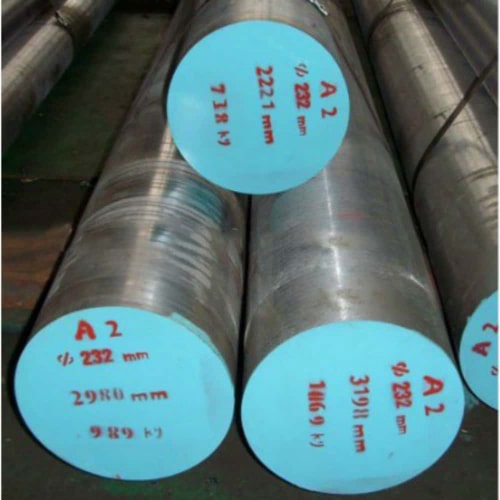

When it comes to high-performance tools and die materials, A2 tool steel has become one of the most trusted choices in modern manufacturing. Whether you are designing cutting dies, forming tools, or wear-resistant components, the mechanical properties of the steel you choose are critical to ensuring long-term durability and reliability.

One of the most essential aspects of any steel used in tooling is its yield strength. The a2 tool steel yield strength is particularly significant because it indicates how well the material resists permanent deformation under stress. This makes it ideal for precision tools that undergo repetitive high-stress applications without failure.

In this blog, we will uncover four game-changing facts about a2 tool steel yield strength that can help you make smarter material choices. We’ll also explore its performance characteristics, typical applications, and how it compares to other tool steels in terms of mechanical properties. By the end, you’ll understand why this steel is such a game-changer for industries that require both toughness and dimensional stability.

What Is A2 Tool Steel and Why Is Yield Strength Important?

A2 tool steel is an air-hardening, cold-work tool steel that belongs to the A-series of tool steels. It is known for its excellent balance between toughness and wear resistance, and it is often chosen for medium-run stamping, blanking, and forming operations.

Understanding Yield Strength in Tool Steels

Yield strength refers to the amount of stress a material can withstand before it begins to deform plastically. In simpler terms, it is the point at which a material stops returning to its original shape when the stress is removed. For tooling and die applications, a high yield strength is critical, as it ensures the material can handle operational loads without permanent bending or warping.

The a2 tool steel yield strength typically falls between 155,000 psi and 185,000 psi (approx. 1069 to 1275 MPa), depending on the heat treatment and processing conditions.

Fact 1: A2 Tool Steel Yield Strength Offers a Perfect Balance for Tooling Applications

Unlike other tool steels that may prioritize either hardness or toughness, A2 tool steel delivers an ideal blend of both. Its yield strength plays a major role in this balance, allowing it to handle mechanical stresses without cracking or losing form.

Key Applications That Rely on A2 Tool Steel Yield Strength

- Cold forming dies

- Shear blades

- Punches and blanking dies

- Trimming tools

- Thread rolling dies

These components endure significant forces, and their structural integrity depends largely on the material’s yield strength.

The Ideal Steel for Medium-Stress Applications

The a2 tool steel yield strength enables it to perform exceptionally in operations that require both resilience and dimensional stability. It can endure repetitive loads without permanent deformation, which is critical in automated production environments.

Fact 2: Heat Treatment Greatly Influences A2 Tool Steel Yield Strength

One of the most important factors affecting yield strength in A2 tool steel is heat treatment. The process transforms the internal structure of the steel, affecting its mechanical behavior and performance under stress.

Heat Treatment Process Overview

- Preheating: Typically at 1450°F (788°C)

- Austenitizing: Heated to 1750–1800°F (954–982°C)

- Quenching: Air-cooled

- Tempering: 400–1000°F (204–538°C), depending on hardness requirement

Different tempering temperatures will affect the resulting yield strength. Higher tempering generally results in slightly lower yield strength but increased toughness.

Table: Yield Strength of A2 Tool Steel Under Different Heat Treatment Conditions

| Heat Treatment Condition | Approx. Yield Strength (psi) | Rockwell Hardness (HRC) | Notes |

|---|---|---|---|

| As annealed | ~85,000 | ~22 | Lowest strength, softest state |

| Air-quenched, tempered at 400°F | ~185,000 | 62–63 | Highest yield strength |

| Tempered at 600°F | ~170,000 | 59–60 | Balanced strength and toughness |

| Tempered at 900°F | ~155,000 | 54–56 | Higher toughness, lower strength |

This table demonstrates how significantly heat treatment can affect the a2 tool steel yield strength. It’s critical to choose the right tempering temperature for your application.

Fact 3: A2 Tool Steel Yield Strength Is Superior to Many Cold Work Tool Steels

When selecting a tool steel, engineers often compare A2 to D2, O1, and S7. The a2 tool steel yield strength provides a distinct advantage over some of these alternatives, particularly when both dimensional stability and toughness are required.

A2 vs D2 Tool Steel

D2 is known for extreme wear resistance and high hardness, but it is more brittle than A2. While D2 may offer higher hardness, its lower toughness and limited yield strength make it less suitable for impact-prone applications.

A2 vs O1 Tool Steel

O1 is oil-hardening and offers good dimensional stability, but it doesn’t match the yield strength of A2. O1 also deforms more easily under load, making it a less durable choice for high-stress tooling.

A2 vs S7 Tool Steel

S7 has higher impact resistance but generally lower wear resistance. A2 strikes a better balance for most general-purpose tools and dies, offering solid yield strength with better wear performance than S7.

Summary of Mechanical Properties

| Tool Steel | Approx. Yield Strength (psi) | Toughness | Wear Resistance | Best Use Case |

|---|---|---|---|---|

| A2 | 155,000–185,000 | High | High | General cold work tools |

| D2 | ~140,000 | Low | Very High | Abrasive environments |

| O1 | ~100,000 | Medium | Medium | Basic cutting tools |

| S7 | ~135,000 | Very High | Low | Impact applications |

From this comparison, it’s clear that the a2 tool steel yield strength gives it a unique advantage across many tooling and forming applications.

Fact 4: A2 Tool Steel Yield Strength Enhances Dimensional Stability in Machining

In high-precision industries like aerospace, automotive, and die making, dimensional stability under stress is non-negotiable. A2’s reliable yield strength helps tools maintain their shape even after numerous cycles of heavy use.

Why Dimensional Stability Matters

When steel yields under pressure, even microscopic deformations can ruin tight tolerances in cutting tools or dies. The excellent a2 tool steel yield strength ensures that components stay within spec, avoiding costly rework or failure.

Machining Advantages

- Reduced warping during machining and heat treatment

- Maintains sharp edges and flatness over time

- Ideal for tight-tolerance parts

This combination of mechanical integrity and stability makes A2 tool steel a top choice for manufacturers who require consistency and precision.

Conclusion

From its excellent performance in cold work operations to its reliable behavior under stress, the a2 tool steel yield strength is a crucial property that makes A2 a game-changing material. It strikes a near-perfect balance between toughness, wear resistance, and dimensional stability, making it suitable for a wide range of tooling applications.

By understanding the four key facts outlined in this article, you can make more informed decisions when choosing materials for your next tooling project:

- A2 offers optimal performance for cold work tools

- Heat treatment dramatically affects its yield strength

- It outperforms many alternatives in strength vs. toughness

- It provides dimensional reliability in precision machining

Whether you’re a tool designer, engineer, or machinist, knowing these characteristics can lead to better product performance and longer tool life.

FAQ

Q1: What is the typical yield strength of A2 tool steel?

A2 tool steel typically has a yield strength between 155,000 and 185,000 psi depending on heat treatment.

Q2: Can A2 tool steel be hardened without compromising its yield strength?

Yes, A2 can be air-hardened and tempered to achieve both high yield strength and toughness, making it ideal for cold work tools.

Q3: Is A2 tool steel yield strength higher than D2?

Generally, yes. A2 has higher toughness and better yield strength, while D2 focuses more on wear resistance and hardness.

Q4: How does tempering affect A2 tool steel yield strength?

Tempering at lower temperatures (around 400°F) yields the highest strength, while higher tempering temperatures reduce strength but improve toughness.

Q5: What is the best application for steel with high yield strength like A2?

High-yield strength steels like A2 are ideal for stamping dies, shear blades, and forming tools where resistance to plastic deformation is critical.