Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

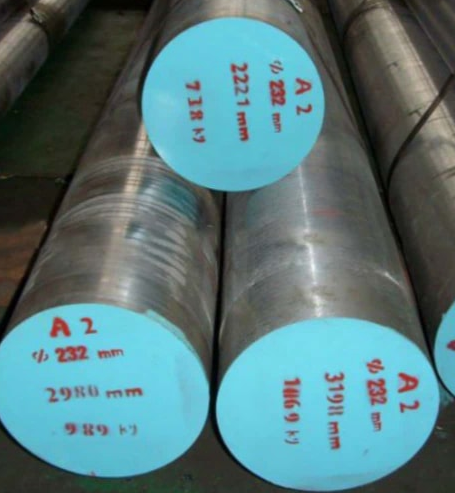

A2 steel is one of the most commonly used tool steels in manufacturing, offering an ideal balance between hardness, toughness, and wear resistance. It is often selected for applications such as cutting tools, punches, dies, and molds due to its excellent characteristics. However, the real question for many manufacturers and engineers is: How does the hardness of A2 steel impact its performance? The hardness of a material directly influences its ability to withstand wear, perform under stress, and maintain precision over time. This blog will dive deep into the crucial relationship between A2 steel’s hardness and its performance, providing 5 key insights that highlight the significance of this property.

Understanding the properties of A2 steel and how its hardness can affect performance is essential for making informed decisions in manufacturing processes. Whether you are selecting a material for tooling, dies, or other heavy-duty applications, A2 steel’s hardness will play a pivotal role in the product’s durability, efficiency, and precision.

NO 1. The Role of A2 Steel Hardness in Tool Performance

The hardness of A2 steel is one of its defining characteristics, particularly when it comes to tools used in high-demand applications. Hardness is not only about the ability of a material to resist deformation but also about its capability to maintain a sharp edge or form under extended use. This is particularly important for tools like cutting edges, punches, and dies that are exposed to constant friction and wear.

A2 steel is known for its excellent balance of hardness and toughness, making it a perfect choice for tools that need to withstand prolonged wear and high-impact conditions without breaking down. Its hardness is achieved through a heat treatment process that allows the steel to maintain strength and precision over extended periods.

Key Points:

- Sharpness and Precision: A2 steel hardness ensures that tools remain sharp even under intense wear. For cutting tools and other precision equipment, maintaining sharpness is essential for high-quality production and efficiency.

- Deformation Resistance: The higher the hardness, the better the tool resists surface deformation, allowing for longer service life and better performance.

- Durability in Harsh Conditions: A2 steel’s hardness ensures tools can withstand long periods of use without significant wear. This leads to fewer replacements and less maintenance, making it an excellent choice in industries where downtime can be costly.

A tool made from A2 steel will offer better resistance to wear and will last longer, minimizing the need for replacements or maintenance. This is especially important in high-production environments where tool failure can lead to significant downtime and increased operational costs.

NO 2. A2 Steel Hardness and Wear Resistance

One of the most crucial performance factors in tools and machinery is wear resistance. The A2 steel hardness directly impacts its wear resistance. A higher level of hardness allows A2 steel to resist the abrasions that occur during use, such as in machining, cutting, or forming materials. As a result, tools made from A2 steel hardness maintain their form and finish over extended periods, reducing the need for frequent tool replacements or re-sharpening.

How Hardness Affects Wear Resistance:

- Abrasive Resistance: A2 steel’s hardness allows it to resist abrasion, making it suitable for applications involving constant friction with hard materials like metals, ceramics, or composites.

- Consistent Performance: With enhanced wear resistance, A2 steel tools maintain their functionality longer, ensuring more consistent performance and reducing operational interruptions.

- Lower Maintenance Costs: Tools made from A2 steel require less maintenance and fewer replacements, which translates into lower overall operational costs for businesses.

Because of its superior wear resistance, A2 steel is often used in manufacturing environments that involve high wear rates, such as metalworking, woodworking, and plastic molding.

NO 3. A2 Steel Hardness and Heat Treatment

The heat treatment process is crucial in determining the final hardness of A2 steel. It is air-hardened, meaning that after being heated to specific temperatures, the steel is allowed to cool in the open air. This process helps develop its distinctive hardness, typically in the range of 55-62 HRC (Rockwell C). The heat treatment process is key to enhancing the steel’s wear resistance and its ability to handle mechanical stresses, making it highly suitable for tooling and machine components.

Effects of Heat Treatment on A2 Steel Hardness:

- Customization: Heat treatment allows manufacturers to adjust the hardness of A2 steel to meet the specific demands of their projects. By controlling the cooling rate, the hardness can be optimized to provide better wear resistance or impact resistance, depending on the needs of the application.

- Improved Durability: A2 steel’s hardness, achieved through heat treatment, ensures that it can resist deformation under high-pressure and high-stress conditions. The resulting durability makes it suitable for tools that need to perform in harsh environments.

- Balance of Hardness and Toughness: While hardness improves wear resistance, it is also important that the steel retains some toughness to withstand sudden impacts. A2 steel’s heat treatment process ensures it strikes the right balance between these two qualities, enhancing its overall performance.

It is important to note that heat treatment not only influences the hardness but also other properties, such as toughness, machinability, and strength, all of which are essential for ensuring the tool’s optimal performance.

NO 4. The Balance Between Hardness and Toughness in A2 Steel

While A2 steel hardness is vital, toughness is equally important. Toughness refers to a material’s ability to absorb energy and resist breaking or fracturing under impact. A2 steel hardness strikes a perfect balance between hardness and toughness. Its moderate hardness allows it to maintain a resilient structure that resists cracking or shattering under high-impact conditions, making it an ideal choice for tools and components subjected to both wear and stress.

How Hardness and Toughness Work Together:

- Wear and Impact Resistance: A2 steel’s hardness ensures that it resists wear, while its toughness allows it to withstand high-impact forces without cracking. This dual capacity makes A2 steel an ideal choice for tools subjected to both abrasion and mechanical stress.

- Long-Lasting Performance: The combination of hardness and toughness ensures that A2 steel tools will perform well over time, even when exposed to varying conditions. This makes them suitable for a wide range of industrial applications, including cutting, molding, and forming.

- Avoiding Brittle Failures: By balancing hardness and toughness, A2 steel maintains a resilient structure that resists fractures or breaking, ensuring that tools stay functional and efficient under extreme stress.

In industries that require durable tools, A2 steel’s balanced hardness and toughness make it an excellent choice for applications such as stamping dies, molds, and cutting tools.

NO 5. A2 Steel Hardness and Machinability

The A2 steel hardness plays a significant role in machinability. While harder materials are generally more challenging to machine, A2 steel hardness is relatively moderate compared to other high-hardness tool steels, making it more machinable. Heat treatment also affects the machinability of A2 steel, and selecting the right techniques is essential to ensure optimal performance.

Factors Influencing Machinability:

- The hardness of A2 steel can make it more difficult to machine, requiring more advanced cutting tools and techniques.

- As the hardness increases, so does tool wear, which means more frequent tool changes and higher maintenance costs.

- However, A2 steel’s moderate hardness compared to other steels allows for relatively easier machining, ensuring that it remains cost-effective for tool manufacturers.

By selecting the correct cutting tools and applying appropriate machining techniques, manufacturers can optimize the machinability of A2 steel to reduce costs and improve the accuracy of the final product.

Table: A2 Steel Hardness and Its Influence on Key Properties

| Property | Low Hardness Range (Brinell) | Medium Hardness Range (Brinell) | High Hardness Range (Brinell) |

|---|---|---|---|

| Wear Resistance | Low | Medium | High |

| Toughness | High | Medium | Low |

| Machinability | High | Medium | Low |

| Strength | Low | Medium | High |

| Fatigue Resistance | Low | Medium | High |

Conclusion

In conclusion, A2 steel’s hardness is a defining feature that significantly impacts its performance across a variety of applications. The combination of hardness, wear resistance, toughness, and machinability makes A2 steel an excellent material choice for many industrial tools. Understanding how A2 steel hardness affects performance is essential for optimizing tool life, efficiency, and overall cost-effectiveness in manufacturing. Whether you’re working with dies, punches, or cutting tools, A2 steel’s carefully balanced hardness ensures that the final product will offer superior performance in demanding environments.

FAQ

What is the typical hardness range of A2 steel?

A2 steel typically falls within the range of 55-62 HRC (Rockwell C) after heat treatment.

Can A2 steel be used for high-impact applications?

Yes, A2 steel offers a balance of hardness and toughness, making it suitable for applications involving both wear and impact.

How does A2 steel compare to other steels like D2 or O1?

A2 steel has moderate hardness compared to D2 or O1, making it more versatile for applications requiring both toughness and wear resistance.

Can A2 steel be further hardened?

A2 steel can be hardened to a certain extent through additional heat treatment, but its toughness may decrease as hardness increases.

Why is A2 steel commonly used in tool-making?

A2 steel’s combination of hardness, wear resistance, and toughness makes it ideal for tools that need to withstand heavy use, such as cutting tools, dies, and punches.