Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

In the world of toolmaking and precision engineering, M2 HSS steel stands as one of the most reliable and versatile materials available. With a well-balanced combination of red hardness, wear resistance, and toughness, it has become the industry standard for high-speed steel applications. Whether you’re purchasing it for cutting tools, cold work dies, or intricate precision parts, making the right buying decision is crucial.

This article will guide you through five essential buying tips for M2 HSS steel, helping you navigate through specifications, suppliers, quality markers, and performance indicators. If you’re in the market for this grade, understanding its chemical makeup, mechanical strengths, and industrial relevance is key to making an informed purchase.

Let’s dive in and uncover what every buyer should know before investing in M2 HSS steel.

Tip 1: Understand the Core Properties of M2 HSS Steel

When considering M2 HSS steel for your applications, the first step is to understand its fundamental properties. Developed as a molybdenum-based high-speed steel in the tungsten–molybdenum series, M2 combines excellent hardness and toughness, making it ideal for a wide range of uses.

Key Characteristics

- Red Hardness: Maintains high hardness even at elevated temperatures, up to 600°C.

- Toughness: Greater than many high-hardness steels like M4, which makes it suitable for shock-load applications.

- Wear Resistance: Superior resistance to wear, essential for cutting tools under frequent use.

- Thermal Stability: Performs exceptionally under high-temperature cutting environments.

- Machinability: M2 is easier to machine compared to older types like T1, improving production efficiency.

M2 HSS steel is widely used in manufacturing twist drills, taps, saw blades, milling cutters, and dies. Its balanced properties also make it a great option for cold working tools and components that require long-term durability.

Tip 2: Evaluate the Chemical Composition of M2 HSS Steel

One of the strongest indicators of M2 HSS steel‘s performance lies in its chemical composition. Each element plays a specific role, enhancing the steel’s performance under various conditions. Here’s a breakdown of its key elements:

Chemical Composition of M2 HSS Steel

| Element | Composition Range (%) | Role in Performance |

|---|---|---|

| Carbon (C) | 0.78–0.88 | Increases hardness and strength |

| Manganese (Mn) | 0.15–0.40 | Improves hardenability |

| Silicon (Si) | 0.20–0.45 | Enhances strength |

| Sulfur (S) | ≤0.030 | Should be minimal to avoid brittleness |

| Phosphorus (P) | ≤0.030 | Kept low to maintain toughness |

| Chromium (Cr) | 3.75–4.50 | Increases hardness and wear resistance |

| Molybdenum (Mo) | 4.50–5.50 | Improves toughness and red hardness |

| Vanadium (V) | 1.75–2.20 | Enhances wear resistance and cutting ability |

| Tungsten (W) | 5.50–6.75 | Provides high-temperature strength |

| Nickel (Ni) | ≤0.30 | Adds to toughness when present |

This combination of elements results in a steel that can endure heavy-duty cutting tasks and maintain integrity even when exposed to significant thermal stress.

Tip 3: Compare Mechanical Properties Before You Buy

When evaluating m2 hss steel, it’s crucial not only to look at its chemical composition but also to understand its mechanical behavior under various working conditions. Whether you’re manufacturing cutting tools, precision dies, or high-load components, the steel’s mechanical characteristics are fundamental to ensuring operational efficiency and product reliability.

Mechanical Properties Overview

The high performance of m2 hss steel is deeply rooted in its mechanical strength and thermal resilience. Here’s a breakdown of the key parameters:

- Factory Hardness: ≤255 HB (Brinell Hardness)

- Post-Quench Hardness: Up to 62–66 HRC

- High-Temperature Hardness: Maintains approximately 48.5 HRC at 600°C

- Tensile Strength: Approximately 1800 MPa

- Flexural Strength: 3.5 to 4.0 GPa

- Impact Toughness: 0.18–0.32 MJ/m²

These figures demonstrate why m2 hss steel is often selected for high-speed and high-precision applications. It’s built to endure severe mechanical stress while maintaining its cutting edge and structural form. For instance, the post-quench hardness ensures that cutting tools retain their sharpness even under high-speed rotation, whereas the high-temperature hardness (red hardness) means the steel doesn’t soften during prolonged use in high-heat environments.

Tip 4: Match the Steel Form to Your Application

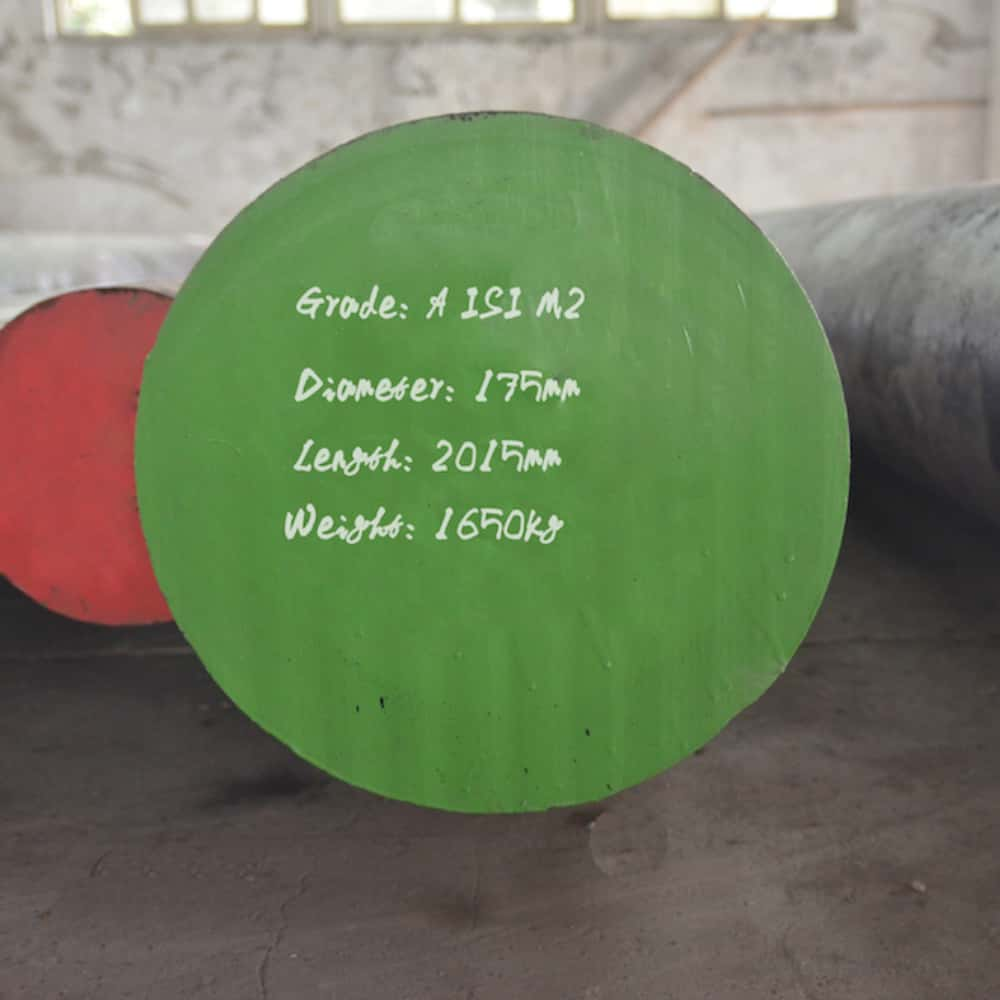

Before finalizing your purchase, assess whether you need M2 HSS steel in round bar form, plate, or another format. The form directly affects how the steel can be processed and applied.

Commonly Available Forms

- Round Bars: Diameter range of 2 mm to 200 mm. Ideal for lathe and CNC applications.

- Steel Plates: Thickness between 2 mm and 200 mm, width between 200 mm and 610 mm. Best for molds and die sets.

Choosing the appropriate form minimizes machining effort and reduces material waste, which ultimately helps optimize your costs.

Tip 5: Source M2 HSS Steel from Reputable Suppliers

No matter how technically sound m2 hss steel is on paper, your real-world results will depend on where—and how—you source it. Supplier credibility can directly impact quality, reliability, and even regulatory compliance for your end products.

What to Look for in a Supplier

- Technical Documentation: Ensure certificates for chemical and mechanical properties are provided.

- Customer Reviews: Check for testimonials, especially regarding wear resistance, red hardness, and consistency.

- Sample Availability: See if small quantities are available for testing before large-scale orders.

- Custom Sizing: Reliable suppliers should offer cutting services to deliver the size and form you require.

Some suppliers may also offer heat treatment services, improving the steel’s properties further based on your specific needs.

Real-World Applications of M2 HSS Steel

Thanks to its high red hardness, superior wear resistance, and outstanding durability, m2 hss steel is used across a wide range of industries—from metalworking and aerospace to tooling and measurement systems. Here are some of its most common and impactful uses:

Cutting Tools

Due to its sharpness retention and high-temperature hardness, M2 is commonly used to manufacture:

- Twist drills

- Milling cutters

- Gear cutters

- Saw blades

Cold Working Dies

The steel’s hardness and wear resistance make it suitable for:

- Cold stamping dies

- Cold extrusion tools

Precision Measuring Tools

Its ability to maintain structural integrity over time also makes it an ideal choice for:

- Gauges

- Precision knives

- Profiling tools

Customer Testimonials

“Reliable Performance in High-Temperature Applications”

“We’ve been using M2 tool steel for several months now, and its performance has exceeded our expectations. The material maintains its hardness even under high temperatures, making it ideal for our precision tools. We’re very satisfied with its reliability and overall quality.”

“Excellent Durability and Consistency”

“M2 high-speed steel has become our go-to choice for manufacturing cutting tools. The consistency and durability of the steel ensure minimal wear and long service life. We highly recommend it for any high-performance tooling applications.”

“Improved Production Efficiency”

“The M2 tool steel we purchased has proven to be an excellent investment. It offers outstanding wear resistance and is easy to machine into the required shapes. Our production efficiency has improved significantly since we switched to this material.”

Conclusion

Purchasing M2 HSS steel is an investment that affects the productivity, durability, and quality of your tools or components. By understanding its chemical composition, mechanical capabilities, form availability, and supplier reputation, you set yourself up for long-term success.

Always choose steel that meets the necessary certifications, and never hesitate to consult with manufacturers about heat treatment options and machining behaviors.

If you’re ready to enhance your cutting performance and tooling lifespan, M2 HSS steel is a smart, future-proof choice for nearly any high-speed steel requirement.

FAQ

What makes M2 HSS steel better than T1 steel?

M2 has superior red hardness, better wear resistance, and improved toughness compared to T1. It’s also more cost-effective for high-speed tool applications.

Can M2 HSS steel be used in high-temperature environments?

Yes, it maintains significant hardness (around 48.5 HRC) even at 600°C, making it excellent for high-speed and high-temperature cutting.

How is M2 HSS steel typically heat treated?

It is usually hardened through quenching and tempered to achieve desired hardness levels of 62–66 HRC.

Is M2 HSS steel suitable for machining?

Yes, M2 is known for good machinability, especially compared to other high-speed steels like M4.

Where can I buy certified M2 HSS steel?

Look for suppliers offering full chemical and mechanical certifications. Many international steel providers offer this grade in round bar and plate forms, along with optional heat treatment services.