Introduction

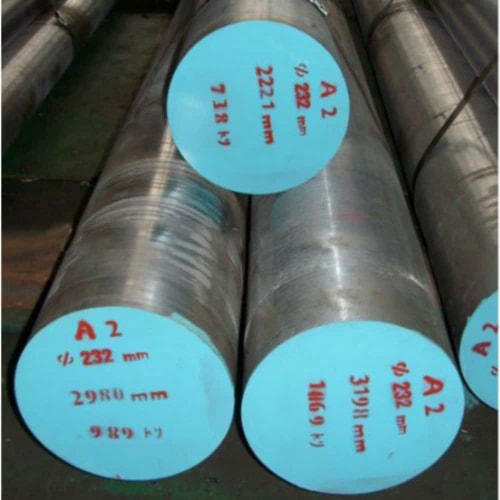

Tool steel A2, a versatile alloy often used in manufacturing industries, has earned a reputation for its exceptional hardness, wear resistance, and toughness. Its unique properties make it an ideal choice for a wide range of applications, from cutting tools and dies to automotive components. In this comprehensive guide, we’ll delve deep into the world of tool steel A2, exploring its composition, properties, heat treatment, and applications. By the end of this article, you’ll have a solid understanding of why tool steel A2 is a preferred choice for many engineers and manufacturers.

Understanding Tool Steel A2

Composition and Properties

Tool steel A2 is an air-hardening alloy steel, primarily composed of iron, carbon, chromium, and molybdenum. These elements contribute to its exceptional hardness, wear resistance, and toughness. The high carbon content provides hardness, while chromium and molybdenum enhance corrosion resistance and improve the steel’s ability to hold an edge.

Heat Treatment

Heat treatment is a critical process for maximizing the properties of tool steel A2. It involves heating the steel to a specific temperature, holding it for a certain period, and then cooling it at a controlled rate. The most common heat treatment process for A2 is air quenching followed by tempering. This process results in a martensitic microstructure, which is responsible for the steel’s high hardness and wear resistance.

Applications of Tool Steel A2

Tool steel A2 is used in a wide range of applications, including:

- Cutting tools: Drills, reamers, taps, and milling cutters made from A2 excel in machining a variety of materials.

- Dies: A2 is commonly used for cold-forming dies, such as those used in the automotive industry.

- Punches: A2’s toughness and wear resistance make it ideal for punching applications.

- Gauges: The precision and dimensional stability of A2 make it suitable for manufacturing gauges.

- Automotive components: A2 is used in various automotive components, such as gears, shafts, and bushings.

Comparing A2 to Other Tool Steels

| Property | A2 | O1 | D2 |

|---|---|---|---|

| Carbon content | 1% | 0.9% | 1.2% |

| Chromium content | 5% | 1.25% | 12% |

| Molybdenum content | 1% | 0% | 0.8% |

| Hardness (HRC) | 58-62 | 58-60 | 60-64 |

| Toughness | High | Medium | High |

| Wear resistance | High | Medium | Very high |

| Corrosion resistance | Good | Good | Excellent |

Factors to Consider When Choosing A2 Tool Steel

- Application: Consider the specific requirements of your application, such as the type of material being machined, the level of precision required, and the operating environment.

- Heat treatment: The choice of heat treatment process will significantly impact the final properties of the tool steel.

- Cost: A2 is a relatively affordable tool steel, but the final cost will depend on factors such as the size and quantity of the material required.

Conclusion

Tool steel A2 offers an excellent combination of hardness, toughness, and wear resistance, making it a versatile choice for a wide range of applications. By understanding the composition, properties, heat treatment, and applications of A2, you can make informed decisions when selecting the right tool steel for your project.

FAQ

What is Tool Steel A2?

Tool Steel A2 is a versatile air-hardening alloy steel known for its excellent combination of hardness, toughness, and wear resistance. It’s widely used in various manufacturing applications.

What are the primary applications of A2 tool steel?

A2 tool steel is used in a wide range of applications, including cutting tools (drills, reamers, taps, milling cutters), dies, punches, gauges, and automotive components.

How is A2 tool steel heat treated?

A2 tool steel is typically heat treated through air quenching followed by tempering. This process results in a martensitic microstructure, which contributes to its high hardness and wear resistance.

What are the advantages of A2 tool steel over other tool steels?

A2 offers a good balance of properties, including high hardness, toughness, and wear resistance, at a relatively affordable cost. It’s also relatively easy to machine and grind.

How do I care for A2 tool steel tools?

To maintain the performance of A2 tools, it’s essential to keep them clean, lubricated, and properly stored. Avoid excessive heat and impact, as these can damage the tool steel.