Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

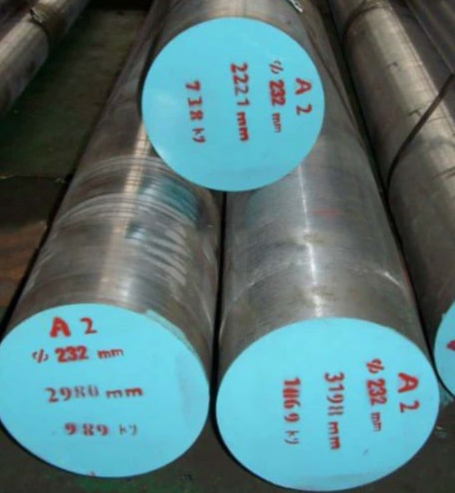

Choosing the right material for your knife is crucial, especially when cutting power and edge retention are priorities. Among the many steel types available, a2 knife steel stands out as a reliable choice for knife enthusiasts and professionals alike. This steel has been widely recognized for its ability to improve cutting efficiency through a blend of toughness, hardness, and wear resistance.

In this article, we will explore 5 proven ways a2 knife steel boosts your cutting power, ensuring that your knives perform at their peak. Alongside these benefits, we will discuss essential care tips and answer some frequently asked questions related to a2 knife steel.

1. Superior Hardness and Edge Retention of A2 Knife Steel

One of the most critical factors that influence a blade’s cutting power is the material’s hardness. Generally, a harder blade will maintain a sharp edge for a longer time, resulting in more precise and effective cutting without the need for frequent resharpening. This directly impacts the overall performance and reliability of the tool during prolonged use.

How Hardness Affects Cutting Power

The hardness of this particular tool steel typically falls within the range of 58 to 62 on the Rockwell Hardness Scale (HRC). This range strikes an excellent balance that allows the blade to hold an edge exceptionally well without sacrificing the toughness necessary to prevent chipping or brittleness. A blade with this level of hardness can remain sharper for extended periods, which means users can rely on it to perform consistently even during intense cutting sessions.

Comparison with Other Steels

Compared to softer blade steels that tend to dull quickly under regular use, this type of steel retains its sharpness remarkably well across various demanding tasks. For example, whether the blade is used for intricate wood carving, precise hunting fieldwork, or everyday kitchen chopping, it maintains cutting efficiency better than many alternatives. This advantage is due in large part to its specific carbon content and alloy composition, which provide a unique combination of hardness and edge durability. As a result, it is a favored choice among skilled craftsmen and knife manufacturers who prioritize long-lasting sharpness.

2. Enhanced Toughness Contributing to Cutting Efficiency

Cutting power is influenced not only by sharpness but also by the toughness of the blade material. Toughness refers to the blade’s ability to absorb impacts without chipping, cracking, or breaking, which is especially important when the knife encounters hard or resistant materials.

Toughness in A2 Knife Steel

This steel belongs to the category of air-hardening tool steels, which means it undergoes a specific heat treatment that increases its structural integrity and toughness. Compared to other steels with similar hardness, it exhibits superior resistance to deformation and mechanical damage. This toughness allows the blade to endure heavy-duty cutting or chopping tasks without suffering edge damage or structural failure.

Impact on Cutting Performance

The interplay between hardness and toughness is crucial for maximizing cutting efficiency. While hardness ensures the blade stays sharp, toughness prevents it from chipping or fracturing during use. Blades made from this type of tool steel maintain a razor-sharp edge even under demanding conditions, such as cutting through tough materials or performing repetitive tasks. This durability translates to increased confidence for users who need reliable cutting tools for various applications, knowing their blade will perform well without frequent maintenance or unexpected failures.

3. Corrosion Resistance and Its Effect on Cutting Longevity

While a2 knife steel is not stainless, it still offers reasonable corrosion resistance compared to many other tool steels. This resistance plays an indirect but crucial role in maintaining cutting power.

How Corrosion Affects Cutting Ability

Corrosion leads to pitting and surface degradation, which can weaken the blade and cause uneven edges. A blade with poor corrosion resistance may lose sharpness quickly and become brittle.

A2 Knife Steel’s Protective Traits

Thanks to its chromium content (typically around 1%), a2 knife steel resists rust and corrosion better than many traditional carbon steels. This resistance helps preserve the blade’s surface integrity and, in turn, its cutting power over time, especially when proper maintenance is observed.

4. Precision Heat Treatment Boosting Cutting Performance

Heat treatment plays a crucial role in enhancing the physical and mechanical properties of this particular tool steel, effectively maximizing its cutting capabilities. Without a carefully controlled heat treatment process, even the best steel alloy would fall short of its potential in sharpness, toughness, and durability.

What Heat Treatment Does for A2 Knife Steel

The process involves heating the metal to specific temperatures, followed by controlled cooling methods, such as air cooling or quenching. For this tool steel, the heat treatment refines its microstructure, transforming the internal grain pattern to increase hardness while preserving necessary toughness. This precise thermal cycle enhances wear resistance and optimizes the blade’s ability to maintain a sharp edge over extended periods.

Benefits to Cutting Power

A blade that undergoes a proper heat treatment exhibits an exceptional balance between rigidity and flexibility. This balance allows the edge to remain sharp and strong, even after prolonged use in challenging conditions. The result is a cutting tool that delivers powerful and precise cuts, reducing the need for frequent resharpening or repairs. Moreover, the enhanced durability means the blade can withstand a variety of environments — from humid kitchens to rugged outdoor settings — without performance degradation.

By focusing on optimizing the heat treatment process, manufacturers ensure the steel delivers peak cutting efficiency, making it a reliable choice for professionals and enthusiasts alike.

5. Versatile Application of A2 Knife Steel Across Cutting Tasks

One of the standout features of this grade of tool steel is its remarkable versatility. Its properties allow it to adapt seamlessly across multiple cutting tasks, which significantly boosts the practical cutting power users experience in day-to-day applications.

Versatility in Use

Whether used in culinary arts, woodworking, or outdoor survival activities, the steel consistently performs at a high level. Its excellent edge retention, combined with strong resistance to wear and impact, enables the blade to handle a broad spectrum of materials and cutting techniques. This flexibility ensures users can trust their tools for everything from fine slicing in the kitchen to heavier chopping tasks outdoors.

User Confidence and Cutting Efficiency

Because this steel reliably holds its edge and resists damage, users can approach their cutting tasks with greater confidence. Knowing the blade will perform as expected reduces hesitation and allows for more precise, efficient handling. This increased efficiency not only improves productivity but also extends the tool’s overall lifespan.

The ability to maintain cutting power in various scenarios means that whether you are preparing meals, crafting wood, or engaging in fieldwork, the blade remains a dependable asset. This adaptability is a key reason why this steel is preferred by knife makers and users seeking performance combined with durability.

Table: Key Properties of A2 Knife Steel Compared to Other Common Knife Steels

| Property | A2 Knife Steel | 1095 Carbon Steel | 440C Stainless Steel | D2 Tool Steel |

|---|---|---|---|---|

| Hardness (HRC) | 58-62 | 55-58 | 56-58 | 58-62 |

| Toughness | High | Moderate | Moderate | High |

| Corrosion Resistance | Moderate | Low | High | Moderate |

| Edge Retention | Excellent | Good | Good | Excellent |

| Ease of Sharpening | Moderate | Easy | Moderate | Difficult |

Conclusion

In summary, a2 knife steel offers an exceptional combination of hardness, toughness, corrosion resistance, and adaptability, making it an outstanding choice for anyone looking to boost their knife’s cutting power. By understanding and appreciating these benefits, users can select blades made from a2 knife steel with confidence, knowing they will deliver reliable performance over time.

Proper maintenance and heat treatment further enhance the material’s natural strengths, making a2 knife steel a versatile and powerful option for various cutting tasks.

FAQ

Q1: Is a2 knife steel suitable for kitchen knives?

Yes, a2 knife steel is often used in kitchen knives due to its excellent edge retention and toughness, though it requires careful maintenance to avoid rust.

Q2: How often should I sharpen a knife made from a2 knife steel?

Sharpening frequency depends on use, but thanks to its hardness, a2 knife steel blades generally require less frequent sharpening than many other steels.

Q3: Can a2 knife steel resist rust?

While a2 knife steel offers moderate corrosion resistance, it is not stainless and needs regular cleaning and oiling to prevent rust.

Q4: Is a2 knife steel difficult to sharpen?

A2 knife steel has moderate ease of sharpening—while it is harder than basic carbon steels, proper sharpening tools and techniques can maintain its edge effectively.

Q5: What types of knives commonly use a2 knife steel?

A2 knife steel is popular in tool knives, hunting knives, and some kitchen knives, valued for its durability and cutting performance.