Table of Contents

Introduction

Steel for construction has long been the backbone of architectural and infrastructural innovation. Today, as global demand for stronger, more sustainable, and cost-efficient structures increases, the materials used in construction must evolve. With advancements in metallurgy, a growing focus on sustainability, and rising performance expectations, steel continues to lead the charge.

At Shandong Qilu Industrial Co., Ltd., we recognize the shifting landscape and are dedicated to providing steel solutions that address both present and future demands. Through advanced production technologies and an unwavering commitment to quality, we supply materials like A2, D2, and D3 tool steels that redefine what’s possible in construction.

Trend 1: High-Performance Alloys Reshaping Structural Standards

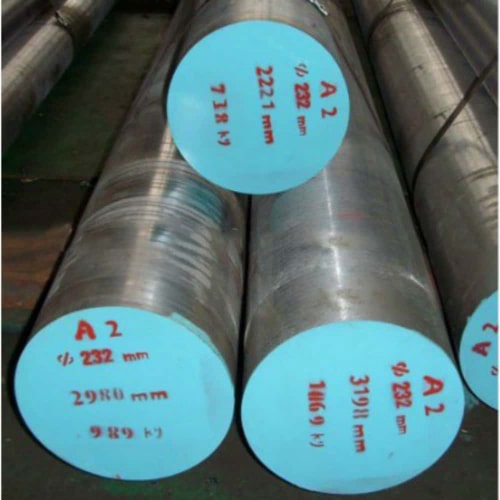

The demand for high-performance steel alloys in construction is rapidly growing as modern infrastructure projects become more complex and safety-focused. Engineers and project managers now prioritize materials with superior mechanical attributes that can endure harsh environments, heavy loads, and long service life. In this context, advanced grades of steel for construction like A2, D2, and D3 are setting new benchmarks across the industry.

Materials such as A2 offer excellent dimensional stability and high toughness, making them especially suitable for high-rise core frameworks where structural integrity is critical. D2, known for its exceptional wear and corrosion resistance, has become a preferred choice for infrastructure like bridges and tunnel linings, where exposure to moisture and stress is continuous. Meanwhile, D3 steel, with its excellent hardness and weldability, is widely adopted in large-span structures, such as industrial plants, warehouses, and sports complexes.

These high-performance tool steels are more than just durable—they are engineered for precision and long-term reliability, key attributes of modern steel for construction. At Qilu, our A2, D2, and D3 grades meet and exceed international standards, delivering trusted performance for clients in demanding environments worldwide.

Trend 2: Sustainability Driving Material Choices

In today’s construction landscape, sustainability is no longer a trend—it’s a fundamental requirement. As urban development accelerates, architects and developers are under increasing pressure to select materials that minimize environmental impact. Steel for construction plays a leading role in this shift due to its high recyclability and long service life, which significantly reduce the need for frequent replacements or repairs.

Modern steel manufacturing practices are now incorporating energy-efficient technologies, lower-emission processes, and more sustainable sourcing. This shift not only helps reduce carbon footprints but also improves the overall environmental credentials of large-scale construction projects.

At Qilu, we are committed to producing steel for construction using environmentally responsible methods. Our tool steels are manufactured with a focus on resource efficiency, utilizing low-emission furnaces and eco-conscious raw materials. By aligning our operations with global sustainability goals, we support our clients’ commitment to green building certifications and environmentally sensitive designs.

For developers aiming to balance durability with eco-friendliness, selecting sustainable steel for construction is a clear and future-proof choice.

Trend 3: Digital Manufacturing and Precision Engineering

As digital transformation reshapes the construction industry, precision and predictability have become non-negotiable. Technologies like Building Information Modeling (BIM), CNC machining, and smart fabrication systems now demand components that meet exact tolerances and consistent performance metrics. This is particularly true for steel for construction, which must integrate seamlessly into prefabricated or modular construction systems.

Any deviation—even by millimeters—can lead to costly project delays or structural misalignments. Therefore, the demand for precision-engineered tool steels is higher than ever.

Qilu answers this need with a digital-first production environment. Our advanced manufacturing lines ensure each batch of A2, D2, D3, or D6 tool steel conforms to strict dimensional accuracy and mechanical consistency. Through rigorous quality control processes, including ultrasonic testing and spectrographic analysis, we guarantee the integrity of every piece of steel for construction that leaves our facility.

This commitment to precision engineering helps our clients maintain project timelines, improve safety, and minimize costly rework—all of which are essential for successful modern construction.

Product Comparison Table

| Grade | Key Properties | Typical Applications | Tensile Strength (MPa) | Corrosion Resistance |

|---|---|---|---|---|

| A2 | High toughness, dimensional stability | Skyscraper cores, industrial structures | 670–710 | Medium |

| D2 | Superior wear and corrosion resistance | Bridges, tunnels, infrastructure | ≥2000 | High |

| D3 | High hardness, good weldability | Large-span constructions, factories | 600–1000 | Medium |

| D6 | Abrasion-resistant, durable | Dies, molds, high-wear components | ≥1320 | Medium–High |

Trend 4: Customization Becoming the Norm

Every construction project is unique, often influenced by local climate conditions, soil properties, architectural vision, and functional requirements. As a result, customization of steel for construction has become the new standard rather than an added option.

Builders now demand materials tailored to their specific engineering challenges. These include custom thicknesses, special surface finishes, unique alloy compositions, or even non-standard bar lengths. Flexibility in specification helps meet design goals without compromising safety or efficiency.

Qilu offers comprehensive customization capabilities across its steel for construction product line. We accommodate requests for forged shapes, hot-rolled profiles, and special mechanical properties with fast turnaround and consistent quality. Our engineers work closely with clients to understand application needs, ensuring the steel we deliver performs precisely as intended.

With over a decade of industry expertise and global project support, Qilu stands out as a trusted partner for tailored steel solutions that meet modern construction expectations.

Trend 5: Global Supply Chain Optimization

The globalization of construction means supply chain reliability is more important than ever. Large-scale projects now source materials from multiple continents, making on-time delivery and consistent quality critical to success. A delay in receiving steel for construction, or receiving material that doesn’t meet specifications, can disrupt entire project timelines and budgets.

To mitigate these risks, contractors are turning to suppliers who offer global reach, transparent logistics, and responsive support.

At Shandong Qilu Industrial Co., Ltd., we maintain a robust international logistics network that ensures our steel for construction products are delivered promptly and according to specification. Our A2, D2, and D3 grades are already supporting major infrastructure projects in regions such as Europe, North America, Southeast Asia, and the Middle East.

Clients rely on our ability to meet tight deadlines, maintain consistent communication, and provide flexible shipping options. In an industry where timing and precision are everything, our optimized supply chain is a key factor in client satisfaction and project success.

Conclusion

Steel for construction is not just about strength anymore—it’s about performance, precision, sustainability, and speed. The trends highlighted above are reshaping how architects, engineers, and developers approach material selection. Shandong Qilu Industrial Co., Ltd. is committed to staying ahead of these trends through continuous innovation, efficient execution, and customer-centric service.

With a product range that includes A2, D2, D3, and D6 steels, Qilu stands ready to support construction professionals with materials designed for the demands of tomorrow.

FAQ

What makes A2, D2, or D3 better than regular carbon steel?

A2, D2, and D3 tool steels outperform standard carbon steel in several critical aspects, especially when it comes to demanding structural applications. These advanced steel grades offer significantly improved mechanical properties, including higher toughness, better wear resistance, and superior dimensional stability. In the context of steel for construction, such properties are essential for components exposed to dynamic loads, temperature changes, and long service cycles. While regular carbon steel may suffice for light-duty structures, tool steels like A2, D2, and D3 ensure long-term performance and safety in high-stakes projects like bridges, industrial facilities, and high-rise buildings.

Are these steels suitable for welding?

Yes, many grades of tool steel used in steel for construction, including D3 and A2, offer good weldability, especially when proper welding procedures are followed. Preheating and post-weld heat treatment are typically recommended to prevent cracking or distortion and to preserve the steel’s mechanical integrity. A2, for instance, maintains dimensional stability even after welding, making it suitable for structural reinforcements. While D2 is more wear-resistant and slightly more challenging to weld, it can still be used successfully with expert handling. Overall, with the right techniques, these tool steels are a reliable option for welded construction elements.

Can Qilu provide custom-sized steel for unique construction needs?

Absolutely. At Qilu, we recognize that no two construction projects are alike, and customization is often essential. That’s why we offer a broad range of steel for construction in both rolled and forged forms, available in bars, plates, blocks, and rings. Whether a client needs non-standard dimensions, specific alloy modifications, or tailored hardness levels, we can deliver precision-made materials to match their exact specifications. Our in-house engineering and production teams work closely with construction firms and design consultants to ensure every custom order supports structural integrity and design efficiency.

How does Qilu ensure steel quality?

Quality is at the heart of everything we do at Qilu, especially when producing steel for construction that must meet demanding safety and performance standards. We implement a comprehensive quality assurance system that includes chemical composition verification, hardness and tensile strength testing, and dimensional inspection. Each batch of steel undergoes rigorous scrutiny using modern laboratory equipment and industry-approved protocols. From raw material sourcing to final packaging, our processes are designed to ensure consistency, traceability, and compliance with international construction codes. This level of control gives clients confidence in using our steel in critical infrastructure.

Is Qilu experienced in international logistics?

Yes, Shandong Qilu Industrial Co., Ltd. has extensive experience managing global logistics for steel for construction products. We serve clients in North America, Europe, Southeast Asia, and the Middle East, and our export team is well-versed in international shipping regulations, documentation, and customs procedures. Timely delivery is a priority, especially for large-scale construction projects with tight deadlines. We coordinate closely with freight carriers and logistics partners to ensure each shipment arrives on time and in perfect condition. Our multilingual support team also ensures clear communication throughout the process, making international transactions smooth and efficient.

✨ Let’s Stay Connected!

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀