Welcome to My Blog! 🌟

Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share more insights, engage with our vibrant community, and post regular updates. Here’s how you can stay connected:

📘 Facebook: Connect with me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Table of Contents

Introduction

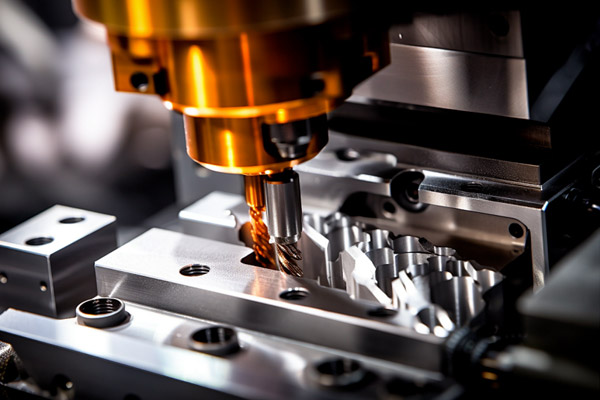

D2 tool steel is a high-carbon, high-chromium steel that is commonly used in the manufacturing of tools, dies, and other industrial components. Known for its exceptional hardness, wear resistance, and strength, D2 tool steel is a popular choice for applications that require durability. However, to maximize the performance and lifespan of tools made from D2 steel, it is crucial to understand the importance of proper heat treatment.

Heat treating D2 tool steel is a process that enhances its mechanical properties, improving tool life and performance. This blog will explore four key reasons why heat treating D2 tool steel is essential for extending the life of your tools.

1. Enhancing Hardness for Better Wear Resistance

One of the most important reasons to heat treat D2 tool steel is to enhance its hardness, which directly contributes to better wear resistance. The heat treatment process involves heating the steel to a specific high temperature, holding it at that temperature, and then cooling it rapidly (known as quenching). This process is often followed by tempering to achieve the desired mechanical properties.

When properly heat treated, D2 tool steel can achieve an impressive hardness rating of 55-62 HRC on the Rockwell scale. This high level of hardness makes D2 steel suitable for applications where tools are subjected to extreme stress, abrasion, and heavy workloads.

By heat treating D2 tool steel, the microstructure is optimized to resist surface wear and deformation. Cutting tools, stamping dies, and other components that require superior wear resistance benefit greatly from this increased hardness. Without heat treatment, D2 steel would be significantly softer and more prone to wear, leading to frequent tool replacement and higher operating costs.

Furthermore, increasing hardness through heat treatment helps D2 steel maintain dimensional stability under mechanical loads, ensuring that parts and tools retain their shape and effectiveness over longer periods.

2. Improving Toughness to Prevent Cracking

Another critical reason to heat treat D2 tool steel is to improve toughness and minimize the risk of cracking. While D2 steel is well-known for its hardness, it can also be brittle if not properly heat treated. Balancing hardness with toughness is essential for ensuring that the tool can withstand impact and shock loads without catastrophic failure.

The tempering phase of the heat treatment process plays a key role here. After quenching, the steel contains high internal stresses that can lead to cracking or breaking. Tempering involves reheating the quenched steel to a lower temperature to relieve these stresses and adjust the hardness to an appropriate level.

Through proper tempering, heat treating D2 tool steel enhances its ability to absorb energy and resist fracture under dynamic loads. This improved toughness ensures that tools made from D2 steel can perform reliably in demanding applications such as die-casting, heavy-duty cutting, and stamping operations where impacts are common.

Without heat treating D2 tool steel appropriately, even minor defects or sharp corners can become initiation points for cracks, significantly shortening the tool’s service life.

3. Increasing Heat Resistance for High-Temperature Applications

Another significant advantage of heat treating D2 tool steel is its improved resistance to high temperatures. Heat treatment allows D2 steel to retain its hardness and mechanical properties even when exposed to elevated temperatures. This is crucial for tools that operate in high-heat environments, such as cutting tools used in metalworking or dies used in injection molding.

Heat resistance is essential for ensuring that tools made from D2 steel maintain their effectiveness over extended periods. Without heat treatment, the material could soften at high temperatures, leading to reduced tool performance and a shorter service life. Proper heat treatment increases the steel’s ability to withstand thermal cycling and high operating temperatures, ensuring it continues to perform at optimal levels.

4. Enhancing Wear Resistance and Edge Retention

The ability of a tool to maintain a sharp edge is a key factor in its effectiveness and longevity. Another important benefit of heat treating D2 tool steel is the significant improvement in wear resistance and edge retention.

D2 steel is often used for applications requiring a keen cutting edge, such as knives, punches, and industrial blades. However, without heat treatment, the material would quickly lose its sharpness, leading to frequent re-sharpening and reduced efficiency.

Through proper hardening and tempering, heat treating D2 tool steel optimizes its microstructure to minimize edge degradation. This means that tools maintain their cutting ability for longer periods, even under continuous use and high-stress conditions.

Better edge retention reduces operational interruptions, increases productivity, and lowers maintenance costs. It also ensures that manufactured parts are consistently of high quality, with fewer defects caused by dull cutting tools.

Factors to Consider When Heat Treating D2 Tool Steel

While heat treating D2 tool steel is essential for improving tool life, several factors should be considered during the heat treatment process to ensure optimal results.

1. Temperature Control

Accurate temperature control is crucial when you heat treat D2 tool steel. Heating the material too quickly or at an incorrect temperature can lead to uneven hardness distribution, internal stresses, or even cracking. Maintaining precise temperatures during the austenitizing, quenching, and tempering stages ensures that the material develops the desired combination of hardness and toughness.

Using programmable furnaces and controlled atmospheres can help achieve consistent temperature profiles, minimizing the risk of errors.

2. Quenching Medium

The choice of quenching medium has a significant impact when you heat treat D2 tool steel. Common media include air, oil, and salt baths, each offering different cooling rates and effects on the steel.

- Air quenching: Reduces distortion but may not be fast enough for some applications.

- Oil quenching: Provides a faster cooling rate but increases the risk of distortion.

- Salt baths: Offer uniform cooling but require careful handling and maintenance.

Selecting the appropriate quenching method is essential for achieving uniform hardness and minimizing the chances of cracking or warping.

3. Tempering Time and Temperature

Tempering is a crucial step when you heat treat D2 tool steel. If the tempering temperature is too high, the hardness may be reduced excessively; if it’s too low, the material may remain brittle. Achieving the ideal balance requires precise control over both time and temperature during tempering.

Multiple tempering cycles may be necessary for some applications to ensure complete stress relief and optimal mechanical properties.

Table: Heat Treatment Process for D2 Tool Steel

| Process Step | Temperature Range | Key Benefits | Time Duration |

|---|---|---|---|

| Preheating | 1,000°F – 1,200°F | Reduces temperature gradient stress | 30-60 minutes |

| Austenitizing | 1,475°F – 1,550°F | Forms austenite structure for quenching | 30 minutes |

| Quenching | ~1,450°F | Rapid cooling to harden the steel | 2-5 minutes |

| Tempering | 300°F – 1,050°F | Reduces brittleness, improves toughness | 1-2 hours |

Conclusion

Heat treating D2 tool steel is an essential process for improving tool life and ensuring that your tools perform optimally in demanding applications. By enhancing hardness, improving toughness, increasing heat resistance, and enhancing wear resistance, heat-treated D2 tool steel provides a reliable solution for industries that require durable and high-performance tools.

For those looking to maximize tool life and reduce maintenance costs, understanding the heat treatment process and selecting the right parameters is crucial. With the proper heat treatment, D2 tool steel can achieve its full potential, providing superior performance and longevity in a wide range of applications.

FAQ

What makes D2 tool steel different from other steels?

D2 tool steel is high in carbon and chromium, making it highly wear-resistant and hard. This steel is ideal for making tools that need to maintain sharpness and durability over time.

How does heat treatment affect D2 tool steel?

Heat treatment improves the hardness, toughness, heat resistance, and wear resistance of D2 tool steel, ensuring it performs well in heavy-duty applications.

Can D2 tool steel be heat treated multiple times?

Yes, D2 tool steel can undergo heat treatment multiple times, although it is essential to control the temperature and cooling process to avoid unwanted changes in the material’s properties.

Is heat treating D2 tool steel expensive?

The cost of heat treating D2 tool steel can vary depending on the method used, but the benefits of improved performance and tool longevity often outweigh the initial costs.