Table of Contents

Introduction

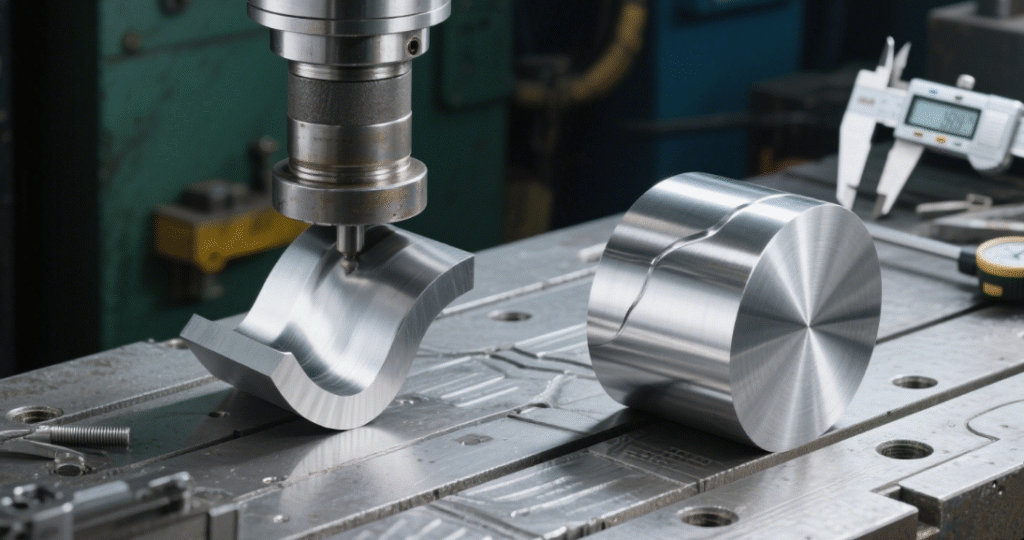

In the realm of precision manufacturing, the selection of the right material is crucial to ensuring that components perform reliably under various conditions. Among the most commonly used steels for high-performance tools and parts are 3Cr13 steel and D2 steel. These two types of steel offer distinct advantages and are used in different applications, depending on their chemical composition and mechanical properties. Understanding the key differences between 3Cr13 Steel vs D2 can help manufacturers select the ideal material for their specific needs.

This article will delve into the chemical composition, mechanical properties, and applications of 3Cr13 Steel and D2 Steel to provide clarity on which material is best suited for different precision manufacturing requirements. Whether you’re in the automotive, aerospace, or tooling industries, understanding these differences can improve efficiency, reduce costs, and enhance product performance.

The Composition: 3Cr13 Steel vs D2

Chemical Composition of 3Cr13 Steel

3Cr13 Steel is a high-carbon, martensitic stainless steel known for its 3Cr13 Steel is a high-carbon, martensitic stainless steel that strikes a balance between strength and corrosion resistance, making it a versatile material for a range of applications. Its chemical composition includes:

- Carbon (C): 0.35–0.45%

- Chromium (Cr): 12–14%

- Manganese (Mn): 0.50%

- Silicon (Si): 0.40%

- Phosphorus (P): 0.03%

This composition allows 3Cr13 to offer both moderate strength and high corrosion resistance. While not as hard as some other tool steels, 3Cr13 excels in environments where resistance to rust and oxidation is more important than extreme hardness. It’s commonly used in applications like cutlery, surgical instruments, and industrial components where good corrosion resistance is essential.

Chemical Composition of D2 Steel

D2 Steel is a high-carbon, high-chromium tool steel known for its excellent wear resistance, toughness, and ability to maintain a sharp edge under demanding conditions. The composition of D2 typically includes:

- Carbon (C): 1.4–1.6%

- Chromium (Cr): 11–13%

- Molybdenum (Mo): 0.70–1.2%

- Vanadium (V): 0.50–1.1%

- Manganese (Mn): 0.1–0.6%

D2 steel is particularly beneficial in cold work tooling applications due to its superior hardness and wear resistance.

Key Differences in Composition

The most significant difference in the composition of 3Cr13 steel vs D2 steel lies in the carbon and chromium contents. D2 steel has a significantly higher carbon content (1.4–1.6%) compared to 3Cr13 steel (0.35–0.45%). This makes D2 much harder and more wear-resistant, ideal for tools that are exposed to high stresses or require long-lasting performance under harsh conditions.

Additionally, D2 steel includes molybdenum and vanadium, elements that further enhance its hardness, wear resistance, and toughness, making it ideal for high-precision applications. In contrast, 3Cr13 steel, with its lower carbon content, focuses more on providing corrosion resistance and moderate strength rather than extreme hardness or wear resistance.

Mechanical Properties: 3Cr13 Steel vs D2

Hardness and Strength:

- 3Cr13 Steel: After proper heat treatment, 3Cr13 steel achieves a hardness range of 52–56 HRC (Rockwell hardness). This level of hardness makes it a solid choice for components that need to withstand moderate wear and mechanical stress. While it’s not as hard as D2 steel, 3Cr13 is sufficient for everyday applications where extreme hardness is not required.

- D2 Steel: D2 steel, on the other hand, can achieve hardness in the range of 58–62 HRC, making it significantly harder than 3Cr13 steel. This makes D2 steel the preferred choice for tooling applications that require prolonged sharpness and wear resistance, such as cutting tools, dies, and molds.

The higher carbon content and overall composition of D2 steel ensure its ability to maintain sharp edges and resist wear in high-stress environments, making it ideal for precision tools in industries like automotive, aerospace, and manufacturing.

Toughness and Impact Resistance:

- 3Cr13 Steel: The toughness of 3Cr13 steel is moderate, meaning it performs well under standard operational conditions but might not withstand the same extreme impact as D2 steel. 3Cr13 is generally used in situations where toughness is not the highest priority, and where corrosion resistance is the main requirement.

- D2 Steel: Despite its higher hardness, D2 steel maintains excellent toughness, especially when it is used in tools subjected to high impact and stress. D2 steel is particularly well-suited for applications in punches, dies, and molds, where both high wear resistance and toughness are required for extended tool life.

Applications: 3Cr13 Steel vs D2

Applications of 3Cr13 Steel

Due to its balanced properties of moderate strength and corrosion resistance, 3Cr13 steel is frequently used in a wide variety of industries for components that do not face extreme wear and stress. Key applications include:

- Cutlery: 3Cr13 steel is commonly used in kitchen knives and other cutting tools, offering a good balance of strength and corrosion resistance.

- Surgical Instruments: With its excellent corrosion resistance, 3Cr13 is often chosen for surgical tools and medical instruments where hygiene and resistance to rust are important.

- Aerospace and Automotive Components: This steel is often found in automotive components, fittings, and parts that require moderate strength and corrosion resistance.

- Industrial Components: It is also used in valves, springs, and other components requiring good corrosion resistance but not extreme hardness.

Applications of D2 Steel

D2 steel is most commonly used in high-performance tooling applications due to its exceptional hardness, wear resistance, and edge retention capabilities. Its applications include:

- Cutting Tools: D2 steel is widely used for manufacturing industrial blades, knives, and shears, thanks to its ability to maintain sharp edges over time.

- Molds and Dies: D2 steel is preferred for injection molds and die-casting tools where its hardness and wear resistance ensure long-term durability and consistent performance in high-volume production environments.

- Automotive and Aerospace Components: D2 steel is used for precision dies and automotive parts, especially in high-stress applications where durability and longevity are essential.

- Punches and Dies: Due to its toughness and hardness, D2 steel is often used for punches, blanking dies, and other tools that require precision and the ability to withstand repetitive impacts without degrading.

| Steel Type | Hardness (HRC) | Wear Resistance | Toughness | Applications |

|---|---|---|---|---|

| 3Cr13 Steel | 52–56 HRC | Moderate | Moderate | Cutlery, Surgical Tools, Aerospace |

| D2 Steel | 58–62 HRC | Excellent | Good | Cutting Tools, Injection Molds, Automotive Dies |

Performance in High-Stress Environments

How D2 Steel Performs in High-Stress Applications

In industrial applications where extreme conditions are present, such as in high-pressure environments, D2 steel consistently outperforms 3Cr13 steel. This is due to its higher carbon content and superior hardness, which make it ideal for parts that must endure wear, abrasion, and impact.

The Role of 3Cr13 Steel in Less Demanding Applications

3Cr13 steel, with its moderate hardness and high corrosion resistance, is best used in applications where stress and abrasion are not as severe. It excels in environments where resistance to corrosion and moderate wear resistance are sufficient.

Conclusion

When it comes to selecting the right material for precision manufacturing, the decision between 3Cr13 steel vs D2 steel boils down to the specific needs of your application. If you are in need of a material that combines corrosion resistance with moderate strength for industrial parts or cutting tools, 3Cr13 steel is a reliable choice. However, for high-performance tooling applications, especially those requiring superior wear resistance, edge retention, and the ability to withstand high stresses, D2 steel is the optimal material.

At Qilu Industrial Co., Ltd., we specialize in providing top-tier materials like D2 steel, P20, H13, and other tool steels, ensuring that your manufacturing process is equipped with the best materials for the job. Our commitment to quality and innovation ensures that your products achieve maximum performance, and our efficient execution helps you stay competitive in the marketplace.

FAQ

1. What is the primary difference between 3Cr13 and D2 steel?

The main difference lies in the carbon content. D2 steel has a much higher carbon content, providing it with superior hardness and wear resistance, making it ideal for cutting tools, while 3Cr13 is more corrosion-resistant and suited for less demanding applications.

2. Which steel is better for cutting tools?

D2 steel is generally better suited for cutting tools due to its high hardness, excellent wear resistance, and ability to retain a sharp edge over time.

3. Can 3Cr13 steel be used for heavy-duty tools?

While 3Cr13 steel offers good strength and wear resistance, it is not as suited for heavy-duty applications as D2 steel, which is engineered specifically for high-stress environments.

✨ Let’s Stay Connected!

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀