Table of Contents

Introduction

When it comes to modern knife steels, the debate of 154cm steel vs. D2 has been going on for decades. Both steels are popular in the knife-making world for their distinct characteristics, strong performance, and reliability in everyday and specialized uses. Whether you are a knife enthusiast, a collector, or simply someone looking for the right material for a blade, understanding how these two steels compare is crucial.

In this article, we will dive into nine excellent comparisons between 154cm steel and D2. We will explore everything from edge retention and toughness to corrosion resistance and ease of sharpening. Along the way, we will highlight how these steels perform in real-world scenarios and help you make an informed decision.

Background of 154cm Steel vs D2

Before we compare, it’s important to understand the origins and metallurgy of these steels.

The History of 154cm Steel

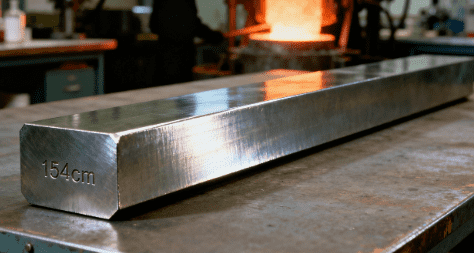

154cm steel was originally developed in the United States as a high-carbon, high-performance stainless steel. Its initial purpose was for turbine blades in aerospace, but it quickly became popular among knife makers due to its hardness, edge retention, and corrosion resistance. It’s often seen as a premium steel choice for mid to high-end knives.

The History of D2 Steel

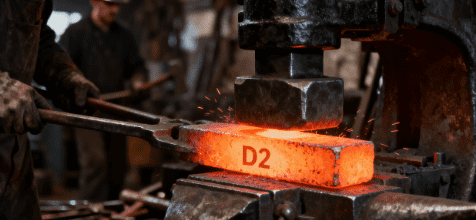

D2 steel, on the other hand, is a tool steel known for its wear resistance and toughness. Originating from industrial applications such as cutting tools and dies, it made its way into the knife industry because of its semi-stainless nature and ability to hold an edge for long periods of time. While not fully stainless, D2 is considered a “semi-stainless” steel because of its high chromium content.

9 Excellent Comparisons of 154cm Steel vs D2

1. Edge Retention

One of the most critical aspects for any knife user is how long the blade stays sharp. In the case of 154cm steel vs D2, both steels offer respectable performance. D2 is known for exceptional edge retention, often lasting longer than 154cm under heavy use. However, this comes at a trade-off—D2 is harder to sharpen once it becomes dull.

154cm, while slightly easier to lose its edge than D2, provides a more balanced performance for those who prefer easier maintenance.

2. Corrosion Resistance

When exposed to moisture, acidic foods, or outdoor environments, corrosion resistance becomes vital. 154cm steel has an edge here due to its stainless steel composition. It can resist rust and staining more effectively than D2, making it more suitable for humid environments or kitchen use.

D2, although it has decent chromium content, is not completely stainless. Over time, it may show signs of patina or minor rust if not properly maintained.

3. Toughness

Toughness refers to how well a blade resists chipping or breaking. 154cm is generally considered tougher than D2, especially under impact or heavy-duty use. For those who require a durable, resilient knife for outdoor tasks, 154cm may offer better performance.

D2, being harder, is somewhat more brittle, which means it is more prone to chipping if used improperly.

4. Ease of Sharpening

The ease of sharpening is another critical point of comparison. For the discussion of 154cm steel vs D2, most users agree that 154cm is easier to sharpen. Its balance of hardness allows users to bring back a fine edge with less effort and standard sharpening tools.

D2, due to its high wear resistance, can be challenging to sharpen. It often requires diamond stones or specialized sharpening systems to achieve a fine edge.

5. Wear Resistance

Wear resistance is where D2 shines. Its tool steel heritage gives it remarkable resistance to abrasion and deformation. This is why D2 is often favored by those who use knives for cutting abrasive materials.

154cm has good wear resistance but does not match D2 in this category. That said, it balances better with corrosion resistance, making it a more versatile choice for many users.

6. Cost and Availability

When choosing between 154cm steel vs D2, budget and accessibility also come into play. Generally, 154cm knives are priced slightly higher due to their stainless nature and popularity among premium knife makers. D2, while often more affordable, is still considered a high-quality steel and offers excellent value.

7. Maintenance Needs

154cm requires less maintenance overall because it resists rust more effectively. A simple wipe and occasional sharpening are often enough to keep it in good condition.

D2 demands more care. Regular oiling and proper storage are necessary to prevent rust spots and corrosion, especially in humid environments.

8. Popular Applications

154cm steel is commonly used in everyday carry knives, tactical blades, and even kitchen knives due to its stainless qualities.

D2 steel finds its place in hunting knives, outdoor survival tools, and heavy-duty applications where wear resistance matters most.

9. Real-World Performance

In real-world usage, the debate of 154cm steel vs D2 depends heavily on what the user values most. For those who want stainless qualities and easier maintenance, 154cm shines. For those who value extreme edge retention and abrasion resistance, D2 may be the superior choice.

Comparison Table for 154cm Steel vs D2

| Feature | 154cm Steel | D2 Steel |

|---|---|---|

| Carbon Content | ~1.05% | ~1.50% |

| Chromium Content | ~14% (full stainless) | ~12% (semi-stainless) |

| Molybdenum Content | ~4% (improves toughness, wear resistance) | ~1% (adds hardness and wear resistance) |

| Hardness (HRC) | 58–61 HRC | 60–62 HRC |

| Edge Retention | Good, 7/10 | Excellent, 9/10 |

| Corrosion Resistance | Very High, 8/10 | Moderate, 5/10 |

| Toughness | Strong, resistant to chipping (7/10) | Brittle under stress, moderate toughness (6/10) |

| Ease of Sharpening | Easy, works with standard stones (8/10) | Harder to sharpen, requires diamond tools (5/10) |

| Wear Resistance | Good, 7/10 | Outstanding, 9/10 |

| Cost | Slightly higher average market price | More affordable in most production knives |

| Maintenance | Low-effort, simple cleaning and occasional oiling | Requires more frequent oiling and care against rust |

Practical Tips for Choosing Between 154cm Steel vs D2

For Everyday Carry

If you plan to carry your knife daily for general use, 154cm is often the more practical choice due to its corrosion resistance and ease of sharpening.

For Outdoor or Hunting Use

If your focus is on outdoor adventures, field dressing, or heavy cutting, D2 might be the better option because of its superior edge retention and wear resistance.

For Collectors and Enthusiasts

Knife collectors often value both steels for different reasons. Many choose to own knives in both 154cm and D2 to enjoy the strengths of each.

Conclusion

In the debate of 154cm steel vs D2, there is no single “better” steel—it depends entirely on your needs and preferences. 154cm offers stainless convenience, toughness, and easier sharpening, while D2 excels in edge retention and wear resistance at a lower price point.

Both steels are proven choices in the knife world, and each has its place depending on the intended use. By understanding the nine excellent comparisons, you can make an informed decision about which steel suits your lifestyle and knife collection.

FAQ on 154cm Steel vs D2

Is 154cm better than D2?

It depends on your needs. 154cm is better for corrosion resistance and ease of maintenance, while D2 is better for edge retention and wear resistance.

Which steel is easier to sharpen?

154cm is easier to sharpen with regular tools, while D2 often requires diamond sharpeners due to its wear resistance.

Can D2 rust easily?

D2 is semi-stainless, so it can rust if not cared for properly, especially in humid environments. Regular oiling helps prevent rust.

Which is more expensive, 154cm or D2?

Generally, 154cm knives are slightly more expensive than D2 knives, though both are widely available in the market.

Which steel is better for outdoor use?

For outdoor and heavy-duty use, many prefer D2 for its edge retention. However, if rust is a concern, 154cm may be the safer choice.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀